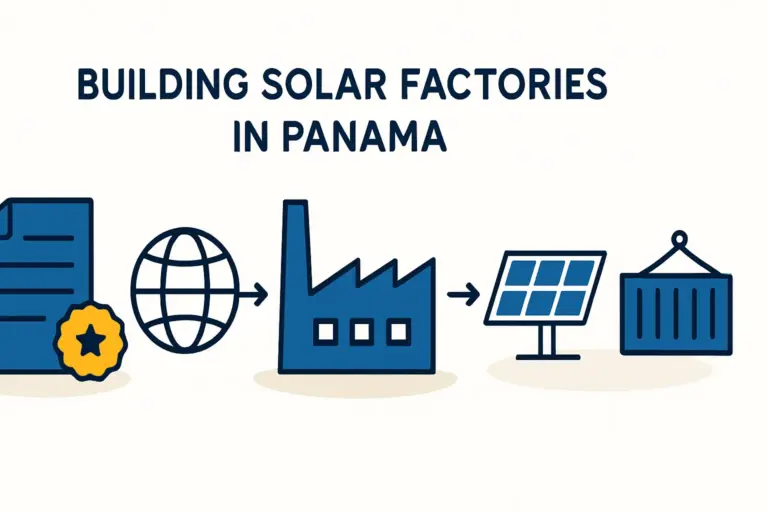

An entrepreneur considering a new venture in Panama’s growing renewable energy sector will likely focus on the impressive local incentives and the country’s strategic location. However, the success of a solar module assembly plant often hinges on a less visible factor: the resilience and efficiency of its raw material supply chain.

While Panama is a global logistics champion, it does not yet produce the highly specialized components required for photovoltaic modules. This presents a critical challenge that must be addressed from the earliest planning stages. Any new manufacturing operation must navigate a global sourcing landscape to secure its most vital inputs.

This article outlines a strategic framework for establishing a reliable supply chain for solar module raw materials in Panama, balancing the realities of international procurement with the potential for future local sourcing.

Panama’s Unique Position: A Logistical Hub for Manufacturing

Panama’s ambition to generate 50% of its power from renewable sources, as outlined in its National Energy Plan 2015-2050, has created significant domestic demand for solar energy projects. For an entrepreneur, this signals a stable and growing local market. Yet, the country’s most significant asset for a manufacturer is its unparalleled logistics infrastructure.

With the Panama Canal serving as a global maritime crossroads and the Colón Free Trade Zone (CFZ) offering a streamlined hub for imports and re-exports, the nation is uniquely positioned to manage a global supply chain. The country’s high ranking in the World Bank’s Logistics Performance Index (LPI) underscores its efficiency in customs, infrastructure, and international shipments.

For a solar module factory, this means that even though raw materials must be imported, bringing them into the country and managing inventory can be more efficient and cost-effective than in many other regions. This infrastructure transforms a potential dependency on imports into a strategic advantage, allowing a manufacturer to source the best components globally and consolidate them efficiently.

Understanding the Core Components of a Solar Module

A sound sourcing strategy begins with understanding the primary components of a solar panel. A typical Bill of Materials (BOM) for a photovoltaic module includes several highly specialized items, each with its own distinct global supply chain. The main raw materials for solar panels are:

-

Solar Cells: The most critical and highest-value components, responsible for converting sunlight into electricity. The vast majority of solar cells are manufactured in Asia.

-

Solar Glass: This is not standard window glass but a highly engineered, low-iron, tempered glass designed for maximum light transmission and durability.

-

Aluminum Frames: These provide structural integrity to the module and facilitate mounting. The required aluminum extrusions must meet precise dimensional tolerances.

-

Encapsulant (EVA or POE): Polymer sheets that laminate the solar cells, protecting them from moisture, vibration, and debris.

-

Backsheet: The rearmost layer of the module, acting as an electrical insulator and protecting the internal components from the elements.

-

Junction Box: A small, weatherproof enclosure on the back of the panel that houses the bypass diodes and wiring.

A new manufacturer in Panama will initially need to procure nearly all of these critical components from international suppliers.

Sourcing Strategy: Local Potential vs. Global Realities

A pragmatic sourcing strategy for a Panamanian solar factory involves a clear-eyed assessment of what must be imported versus what could be sourced locally over time.

International Procurement: The Necessary First Step

For the most technologically sensitive components, global sourcing is the only viable option for a new facility.

-

Solar Cells, Encapsulant, and Backsheets: The production of these materials requires significant capital investment and specialized chemical and electronics manufacturing expertise. Today, this supply chain is heavily concentrated in China and other parts of Southeast Asia. A new factory in Panama must establish relationships with these established international suppliers.

-

Solar-Grade Glass: While Panama has glass manufacturers, producing specialized low-iron, anti-reflective solar glass is a distinct industrial process. Initially, this component will need to be imported from major global producers.

The key is to leverage the Colón Free Trade Zone to manage these imports. By establishing a logistics base within the CFZ, a company can import components in bulk, deferring import duties until the materials are moved to the factory for production. This strategy improves cash flow and allows for a strategic inventory buffer to protect against shipping delays.

Local Sourcing: The Opportunity for Growth

While critical components must be imported, a manufacturer can build resilience and support the local economy by sourcing other necessary goods and services within Panama.

-

Aluminum Frames: Panama has an existing aluminum extrusion industry. The primary task is to identify and qualify a local partner capable of meeting the precise tolerances and quality standards required for solar module frames. This can offer significant cost savings on shipping and import logistics.

-

Packaging Materials: Items like cardboard boxes, protective corners, and wooden pallets are ideal candidates for local sourcing.

-

Labor and Ancillary Services: All labor, construction services, and factory maintenance can be sourced from the local Panamanian market.

Navigating Logistics and Quality Control

Establishing a global supply chain requires meticulous planning that goes beyond simple procurement. A robust system for logistics and quality control is fundamental to the operation’s long-term success.

Key considerations include:

-

Supplier Qualification: Vetting international suppliers thoroughly is crucial. This involves not only assessing their product specifications and certifications but also their production capacity and financial stability. Based on experience from J.v.G. turnkey projects, working with pre-qualified suppliers can significantly de-risk the launch of a new solar module manufacturing line.

-

Quality Control (QC): A multi-stage QC process is essential. This should include inspections at the supplier’s factory before shipment, as well as incoming quality checks once materials arrive at the Panamanian facility. Neglecting this step can render entire batches of expensive components unusable.

-

Freight and Customs: Partnering with an experienced freight forwarder and customs broker is critical. These experts can navigate the complexities of international shipping, insurance, and Panamanian customs clearance, ensuring a smooth flow of materials.

A Phased Approach to Building a Resilient Supply Chain

A prudent approach is to develop the supply chain in phases, prioritizing stability at launch while progressively integrating local content.

-

Phase 1 (Year 1-2): Rely exclusively on established, pre-vetted international suppliers for all core module components. This ensures the factory can produce certified, high-quality modules from day one, which is essential for building market credibility.

-

Phase 2 (Year 2-4): Begin a local supplier development program. Focus on qualifying a Panamanian aluminum extruder for frames and sourcing all packaging materials locally. This transition reduces logistics costs and shortens lead times for these items.

-

Phase 3 (Year 5+): Explore longer-term opportunities for greater localization. This could involve partnerships or joint ventures to encourage the domestic production of components like junction boxes or even solar glass, should the market scale sufficiently.

This phased strategy allows a new enterprise to manage risk effectively, focusing first on operational excellence before taking on the added complexity of local supplier development.

Frequently Asked Questions (FAQ)

Can I source all solar panel materials within Panama?

Currently, it is not possible to source all critical, high-tech components like solar cells, solar-grade glass, and encapsulant from within Panama. A new factory must plan for international procurement of these items.

What is the biggest supply chain risk for a new factory in Panama?

The primary risks are geopolitical or logistical disruptions affecting shipping lanes from Asia, which is the main source of solar cells. Another significant risk is inconsistent quality from suppliers. Both risks can be mitigated through careful supplier diversification, robust quality control, and maintaining a buffer stock of critical materials—a strategy made much easier by facilities like the Colón Free Trade Zone.

How does the Colón Free Trade Zone help a solar manufacturer?

The CFZ provides significant advantages. It allows a company to import and warehouse raw materials without immediately paying import duties and taxes. These fees are levied only when the goods are moved into the national territory for manufacturing. This improves cash flow and creates a cost-effective hub for managing inventory.

How much working capital should be allocated for raw materials in the business plan?

A common practice is to allocate enough working capital to cover at least two to three months of production inventory. This figure can vary based on supplier payment terms and shipping lead times. A detailed financial forecast in the business plan is essential for determining the precise amount required for your specific production capacity.

Your Next Steps in Planning

For entrepreneurs in Panama, the path to successful solar module manufacturing is clear. It begins not with machinery, but with a meticulously planned supply chain strategy. The country’s world-class logistics infrastructure provides a powerful advantage, but it must be paired with a realistic understanding of the global landscape for specialized solar components.

By focusing on a phased approach that prioritizes quality and reliability with established international suppliers from the start, a new enterprise can build a strong foundation. Over time, it can strategically increase local sourcing to enhance efficiency and contribute to the growth of Panama’s domestic industrial capacity. The key is to transform the necessity of importation into a well-managed, strategic strength.