Imagine a newly commissioned solar module factory in Port Moresby. The advanced machinery is installed, the supply chain is established, and the market is ready. But the success of this venture hinges not on the technology, but on the local team tasked with operating it.

For entrepreneurs considering entry into Papua New Guinea’s burgeoning solar sector, building a skilled workforce is the most critical—and often least understood—variable. The opportunity is significant. With a national electrification goal of 70% by 2030, PNG’s demand for renewable energy solutions is clear. Yet, transforming a motivated labor pool into a high-performing manufacturing team requires a deliberate and culturally aware strategy. This article outlines a practical framework for recruiting, training, and retaining a local workforce in PNG, turning a potential challenge into a sustainable competitive advantage.

Understanding the Labor Landscape in Papua New Guinea

Before a training program can be designed, it is essential to understand the unique characteristics of PNG’s labor market. A successful strategy must be built on this reality, not on assumptions imported from other regions.

Research from institutions like the National Research Institute of PNG and the World Bank highlights several key factors that define the context:

-

A Youthful Demographic: Over 60% of PNG’s population is under the age of 25. This ‘youth bulge’ represents a vast reservoir of potential talent, eager for formal employment and new skills. However, it also means the workforce is largely inexperienced.

-

Educational Foundation: While primary school enrollment is relatively high, the transition rate to secondary and tertiary education, particularly in technical fields, is lower. This means recruitment should focus on aptitude and trainability rather than formal qualifications.

-

The Informal Economy: A significant portion of the population is engaged in the informal or agricultural sector. For many, a solar factory will be their first experience in a structured, industrial environment with rigorous safety and quality standards. This transition requires careful management and clear communication.

Recognizing these factors is the first step. The goal is not to view them as limitations, but as the parameters needed to design a highly effective, ground-up workforce development program.

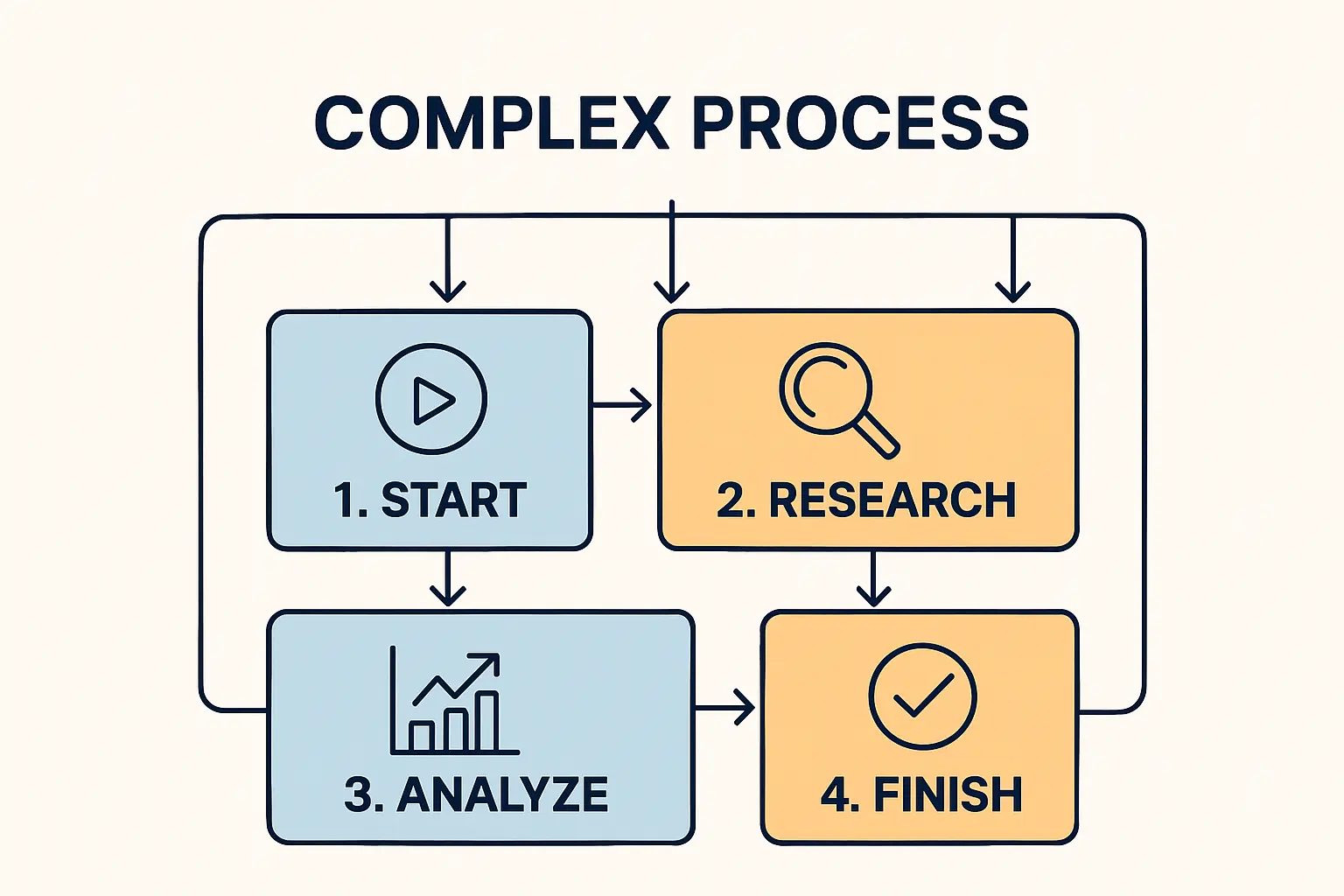

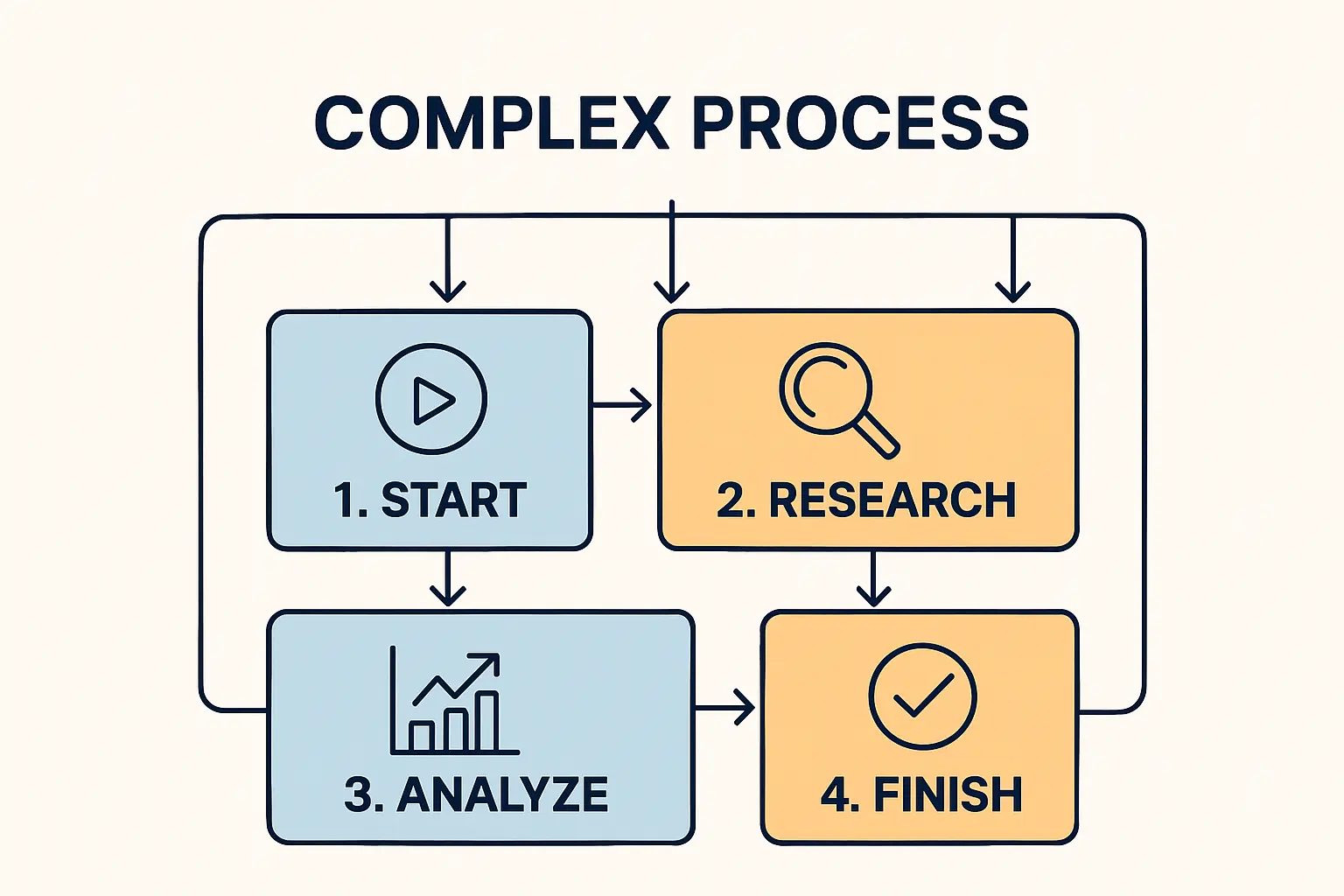

A Three-Pillar Framework for Workforce Development

A robust workforce strategy can be built on three interconnected pillars: Strategic Recruitment, Structured Training, and Long-Term Retention.

Pillar 1: Strategic Recruitment

Finding the right people is about looking for potential, not just prior experience. In a market where specific solar manufacturing skills are non-existent, the focus must shift to core attributes.

-

Sourcing Channels: Collaborate directly with Technical and Vocational Education and Training (TVET) centers. These institutions are a primary source of individuals with foundational technical aptitudes and a demonstrated interest in hands-on work.

-

Assessment Criteria: Prioritize dexterity, attention to detail, a methodical approach to tasks, and a strong willingness to learn. Simple, practical tests can be more indicative of future performance than a formal interview. Experience from J.v.G. turnkey projects in similar emerging markets shows that a candidate’s attitude is a far better predictor of success than their initial skill set.

Pillar 2: Structured Technical Training

After recruitment, a systematic training process builds the team, bridging the gap between general aptitude and the specific demands of solar module assembly.

Phase 1: Foundational Knowledge and Safety

Before an employee touches any equipment, they must understand the ‘why.’ This phase covers basic electrical principles, material handling, and, most importantly, workplace safety protocols (EHS). A deeply ingrained safety culture is non-negotiable.

Phase 2: Machine-Specific, Competency-Based Training

This is the core of the technical training. Each operator must be trained to proficiency at their specific station. This includes:

-

Stringer Operators: Learning to handle delicate solar cells and manage the automated soldering process.

-

Layup Technicians: Precisely assembling the layers of the module (glass, EVA, cells, backsheet) ahead of lamination.

-

Laminator and Framer Operators: Managing the machinery that encapsulates and provides structural integrity to the finished panel.

-

Testing and Quality Control: Using equipment like sun simulators and EL testers to certify module performance and identify internal defects.

Training should be hands-on, repetitive, and supervised by an experienced technician. The ‘Train the Trainer’ model is particularly effective here; identify early high-performers from the local team and invest in developing them into future trainers. This creates a self-sustaining system for scaling the workforce. A comprehensive understanding of the full production line depends on this deep knowledge of all key manufacturing machines.

Phase 3: The Culture of Quality

Every team member must be trained to be a quality inspector. This involves teaching them to visually identify common defects like microcracks, soldering issues, or misaligned cells. Fostering this sense of ownership at every stage of the line is crucial for minimizing waste and ensuring the final product meets international standards.

Pillar 3: Long-Term Retention and Skill Progression

Training is an investment, and protecting that investment requires a clear retention strategy. High staff turnover can cripple a new manufacturing operation.

-

Career Pathways: Define clear opportunities for advancement. An assembly operator can progress to a team leader, a quality assurance specialist, or a maintenance technician. This visibility gives employees a reason to stay and grow with the company.

-

Fair Compensation: Provide a competitive wage and benefits package that positions the company as a desirable employer in the formal sector.

-

Positive Work Environment: Acknowledge the cultural transition many employees may be making. A supportive management style, clear communication, and a sense of shared mission—contributing to PNG’s energy independence—can be powerful motivators beyond the paycheck.

The Business Case: How Investment in People Drives Profitability

A well-structured workforce development program is not a cost center; it directly drives business success. The investment required for a solar factory is significant, and optimizing the workforce is key to maximizing its return.

-

Reduced Defects & Higher Yield: Well-trained operators produce higher-quality modules, leading to less material waste and a higher percentage of A-grade products.

-

Increased Uptime: Staff with basic maintenance and troubleshooting skills can resolve minor issues without waiting for senior technicians, improving overall equipment effectiveness (OEE).

-

Lower Turnover Costs: Retaining skilled staff avoids the recurring expenses of recruiting and training new employees.

-

Stronger Social License: Investing in a local workforce builds goodwill and strengthens relationships with local communities and government stakeholders—a crucial asset for any long-term industrial project in PNG.

Frequently Asked Questions (FAQ)

-

How long does it typically take to train a new solar module assembly operator?

For a single station (e.g., stringer operation), a new recruit with good aptitude can typically be trained to a proficient level within 4 to 6 weeks. This includes foundation/safety training and hands-on, supervised practice. -

What is the ideal educational background for recruits?

A diploma from a TVET institution is beneficial but not essential. The most important qualities are good hand-eye coordination, the ability to follow structured processes, and a commitment to quality. A focus on practical aptitude over academic credentials often yields the best results. -

Are there government programs in PNG that can support this training?

The PNG government, through bodies like the National Training Council, often supports initiatives aimed at vocational training and skills development. Entrepreneurs should explore potential partnerships or subsidies for accredited training programs that align with national development goals. -

What is the typical staff size needed for a small-scale (20–50 MW) assembly line?

For a semi-automated line operating a single shift, a workforce of 25–40 employees is a realistic estimate. This includes operators, quality control personnel, maintenance staff, and administrative support. -

How critical is it to bring in expatriate trainers initially?

Bringing in an expatriate trainer is highly recommended, at least initially. An experienced technical trainer is essential for the first phase to correctly set up processes, transfer knowledge effectively, and implement the ‘Train the Trainer’ program. Their goal should be to make themselves redundant by developing a self-sufficient local training capability within the first 12-18 months.

Conclusion: Your Workforce as a Strategic Asset

Entering the solar manufacturing sector in Papua New Guinea is a venture with immense potential. While discussions often focus on machinery and finance, the ultimate success of the operation will be decided by the people on the factory floor.

By implementing a deliberate framework for recruitment, training, and retention—one tailored to the realities of the PNG labor market—an entrepreneur builds more than just a product. They build a capable, motivated, and loyal team that becomes the factory’s most valuable and sustainable asset. This focus on the human element is critical to the comprehensive planning required for a successful launch.