An entrepreneur planning to enter the solar manufacturing market often focuses first on technology and machinery. Long-term success, however, often hinges on a more foundational decision: where to build the factory.

In a country like Peru, with its growing economy and strategic push for industrialization, choosing the right location within a designated industrial zone is critical. A plot of land that seems ideal on paper can introduce unforeseen operational challenges related to power, logistics, or labor.

This guide offers a framework for evaluating industrial parks in Peru for solar module manufacturing. It moves beyond simple cost analysis to focus on the core infrastructure requirements that directly impact production efficiency, supply chain reliability, and overall profitability. Understanding these factors is essential for any investor looking to establish a sustainable manufacturing presence in the region.

Understanding Peru’s Industrial Landscape

Peru is actively positioning itself as an attractive manufacturing hub, benefiting from a stable economic outlook and strategic government initiatives. The development of modern, large-scale industrial parks is central to this vision. These zones are not merely collections of empty lots but master-planned ecosystems designed to support industrial operations with integrated infrastructure.

For an entrepreneur, locating within a designated park like the Parque Industrial de Ancón offers significant advantages over a standalone site. These benefits include streamlined permitting, pre-installed utilities, and better access to transportation networks. As global supply chains shift, Peru’s “nearshoring” appeal makes it a compelling location for supplying both domestic and regional markets.

The Four Pillars of Site Selection for a Solar Factory

A thorough evaluation comes down to four critical pillars. Overlooking any one of them can lead to significant operational friction and increased costs down the line.

Pillar 1: Logistics and Port Proximity

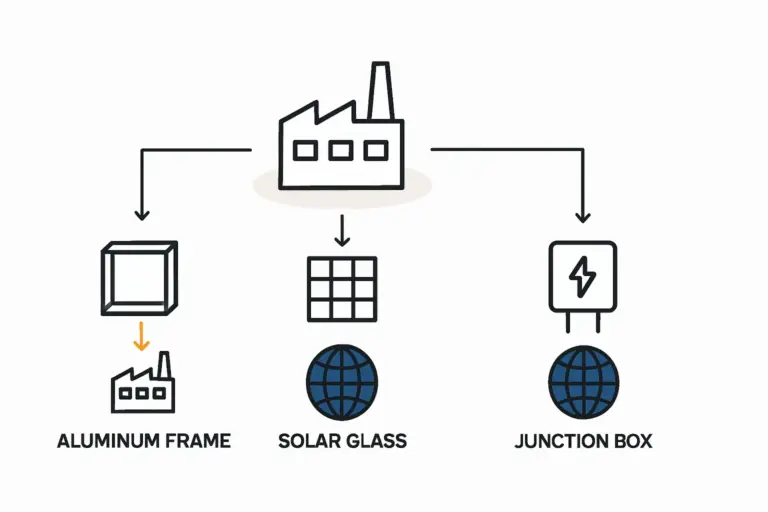

A solar module factory operates as part of a global supply chain. Key raw materials—such as solar cells, tempered glass, and EVA encapsulant—are typically imported, while finished modules may be destined for export. Efficient access to a major seaport is therefore not a luxury, but an economic necessity.

Key considerations include:

-

Proximity to Major Ports: The distance to the Port of Callao, South America’s premier Pacific gateway, directly impacts inland transportation costs and delivery times. Every kilometer adds to the expense of both incoming materials and outgoing products.

-

Future Developments: The new Chancay Megaport north of Lima is set to become a major regional hub, drastically reducing transit times to Asia. Industrial parks with direct access to this new infrastructure, such as Ancón, will gain a significant competitive edge.

-

Road and Rail Infrastructure: The quality and capacity of road networks connecting the industrial park to the port must be evaluated. Traffic congestion and poor road conditions can create logistical bottlenecks and disrupt production schedules.

Pillar 2: Power and Energy Infrastructure

Solar module manufacturing is an energy-intensive process. Machines like laminators and cell stringers require a constant, stable supply of high-quality electricity to operate reliably. Power fluctuations or outages can cause equipment damage, material waste, and costly production downtime.

An ideal site must offer:

-

Grid Stability: The factory must connect to Peru’s national grid, the Sistema Eléctrico Interconectado Nacional (SEIN), which is generally robust. Even so, it is crucial to assess the stability and capacity of the local substation serving the industrial park.

-

Redundant Energy Sources: Relying on a single power source is a major business risk. Industrial zones with access to the Camisea natural gas pipeline, such as those in Lurín, offer a vital advantage. Natural gas can power on-site generators, providing a reliable and cost-effective secondary energy source.

-

Power Quality: The assessment should extend beyond mere availability to include power quality, such as consistent voltage and frequency. Poor power quality can degrade the performance and lifespan of sensitive manufacturing equipment.

Pillar 3: Labor and Technical Skill Access

A factory is more than machines and buildings; it needs a skilled, reliable workforce. While automation plays a large role, a typical 50 MW solar module factory still requires a dedicated team for operations, maintenance, quality control, and administration. The local availability of talent directly influences how many employees you need for a solar module factory.

Factors to evaluate include:

-

Proximity to Urban Centers: Sites near major metropolitan areas like Lima provide access to a larger and more diverse labor pool, making it easier to recruit technicians, engineers, and administrative staff.

-

Local Skill Base: Assess whether the surrounding area has a history of industrial activity. A region with an existing manufacturing base will likely have a workforce familiar with factory environments, reducing the training burden.

-

Accessibility and Transport: The site must be reasonably accessible for employees via public or private transportation. A remote location can make it difficult to attract and retain qualified personnel.

Pillar 4: Physical Site and Building Suitability

Finally, the physical characteristics of the site itself must align with the specific needs of a solar factory. The plot of land is just the starting point; it must be suitable for the complex construction and operational phases ahead.

The analysis should cover:

-

Zoning and Permitting: Confirm that the industrial park’s zoning regulations explicitly permit manufacturing activities of this scale and type, which simplifies the approval process.

-

Scalability: A common planning error is acquiring a site that only fits the initial production line. Consider future expansion. The site should have enough space to add a second or third line as the business grows, avoiding a costly relocation.

-

Geotechnical and Environmental Conditions: Before acquisition, a thorough site survey is necessary to understand soil stability, water table levels, and potential environmental constraints. These factors influence foundation design and overall construction costs, a key part of the building requirements for a solar module factory.

A Practical Evaluation: Ancón vs. Lurín

Applying this four-pillar framework to two of Lima’s prominent industrial areas highlights the practical trade-offs involved.

Parque Industrial de Ancón: As a new, state-promoted megaproject, Ancón is designed for large-scale, modern industry. Its key advantage is its strategic location relative to the future Chancay Megaport, positioning it as an ideal hub for export-oriented manufacturing. It offers large, undeveloped plots perfect for businesses with ambitious growth plans.

Lurín Industrial Area: Lurín is a more established industrial zone south of Lima. Its primary strength lies in its mature infrastructure, including direct access to the Camisea natural gas pipeline. For a manufacturer prioritizing energy stability and redundancy, this is a decisive factor. Its proximity to the existing Port of Callao is also a strong logistical advantage.

The choice depends on business strategy. An export-focused operation with a long-term view might favor Ancón, while a manufacturer prioritizing immediate operational stability may lean toward Lurín.

Frequently Asked Questions (FAQ)

Why is port proximity so critical if we plan to sell modules locally in Peru?

Even if 100% of your sales are domestic, nearly all critical raw materials—solar cells, glass, backsheets, and aluminum frames—are imported. Your entire production line depends on a reliable and cost-effective inbound supply chain that begins at the port.

Is the national power grid in Peru reliable enough for sensitive manufacturing?

The SEIN grid is one of the more stable in the region. However, for any high-value manufacturing process, best practice is to mitigate all potential risks. A secondary power source, like a natural gas generator, or at minimum high-quality uninterruptible power supplies (UPS) and voltage stabilizers for critical machinery, is a prudent investment to prevent losses from even brief interruptions.

What are the hidden costs of selecting a remote, cheaper site?

Cheaper land often brings higher long-term operational costs. These can include building your own access roads, higher transportation expenses for every shipment, increased logistical complexity, and difficulty attracting skilled employees who may be unwilling to commute to a remote location.

How long does it typically take to get a site operational?

Site selection and preparation are foundational stages in the project timeline. Choosing a site within a well-organized industrial park can shorten the path from plan to production. Once a suitable site is secured, a structured approach makes it possible to understand how to start a solar module factory and achieve a complete setup in under a year.

Conclusion: Your Next Steps in Site Evaluation

Selecting a location for a solar module factory is a strategic decision that extends far beyond a real estate transaction. The chosen site fundamentally shapes the company’s cost structure, operational efficiency, and capacity for future growth. By systematically evaluating potential locations against the four pillars of logistics, power, labor, and site suitability, entrepreneurs can lay a strong foundation for a successful manufacturing operation in Peru.

The next logical step is to conduct a detailed feasibility study for the top one or two sites. This involves deeper due diligence, preliminary engineering assessments, and financial modeling based on the specific conditions of each location. Based on experience from J.v.G. turnkey projects, this detailed planning phase is where a promising venture transforms into a viable, bankable project.