An investor has identified Peru as a promising location for a new solar module factory, drawn by its stable economic framework and growing demand for renewable energy. With initial feasibility studies complete, a critical decision is at hand: where to build? While factors like logistics and tax incentives are on the checklist, one variable is proving particularly decisive for long-term success—the availability of a skilled and stable workforce.

This analysis compares Peru’s two primary industrial centers, Lima and Arequipa, focusing on sourcing, training, and retaining the technical labor required for solar panel production. Understanding the distinct characteristics of each city’s labor market is essential for developing a sound operational strategy.

The Strategic Importance of Labor in Solar Manufacturing

In the automated environment of a modern solar module factory, the quality of the final product depends directly on the skill of the team overseeing the process. Solar manufacturing is not merely an assembly line; it is a technical process that demands precision and consistency.

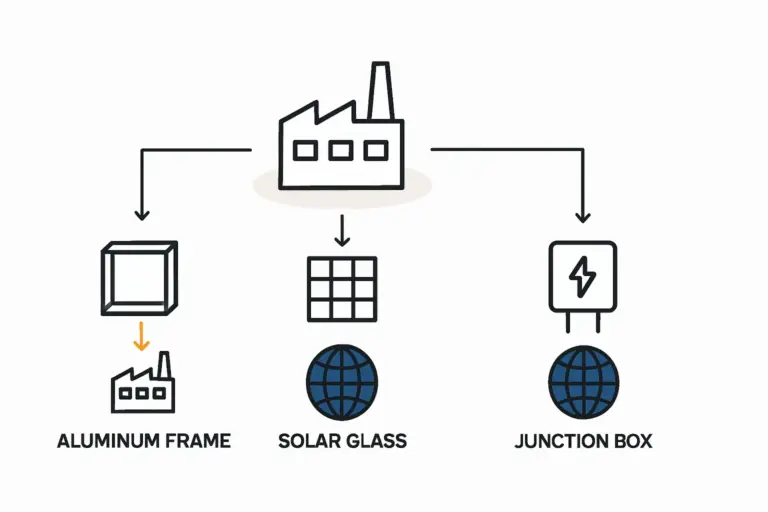

The required workforce includes individuals with skills in several key areas:

- Electronics and Electrical Systems: For handling cell stringing, junction box application, and testing.

- Mechanical Aptitude: For operating and maintaining laminators, framers, and other automated equipment.

- Quality Assurance: For visual inspection, electroluminescence (EL) testing, and ensuring every module meets certification standards.

Securing a team with this foundational expertise is a critical step, and the choice of location will significantly influence both the ease and cost of building it.

Lima: The Economic Powerhouse

As Peru’s capital and largest city, Lima is the nation’s undisputed economic engine, accounting for over 43% of the country’s GDP. With a metropolitan population exceeding 10 million, it offers an immense and diverse talent pool for any industrial enterprise.

The Labor Market Landscape

Lima’s sheer size translates to a larger number of available technicians, engineers, and manufacturing specialists. This availability, however, comes with intense competition. A new solar factory in Lima will be competing for talent not just with other manufacturers but also with thriving logistics, services, and commercial sectors. This competitive pressure drives up wage expectations and the overall cost of living—crucial factors in any financial projection.

Key Educational Institutions

A primary source of technical talent in the Lima region is SENATI (National Service of Industrial Work Training). As one of Peru’s premier technical institutes, it produces a steady stream of graduates with practical skills in industrial electronics, automation, and manufacturing processes. A factory located in Lima has direct access to this pipeline of newly trained talent.

Business Implications for a Solar Factory

Advantages: Direct access to the largest talent pool in the country, proximity to the port of Callao for logistics, and close connections to government agencies and corporate headquarters.

Challenges: Higher labor costs, increased competition for skilled employees, and the potential for greater workforce turnover as staff are courted by other established companies.

Arequipa: The Industrial Southern Hub

Arequipa, Peru’s second-largest city with a population of over 1.1 million, is often called the ‘Southern Hub’. It has a robust and long-standing industrial identity, built primarily around the mining and textile sectors. This has cultivated a workforce with strong industrial discipline and technical aptitude.

The Labor Market Landscape

While the labor pool in Arequipa is smaller than Lima’s, it is highly concentrated in industrial skills. Competition for technical talent is less fierce, which can lead to greater workforce stability and lower employee turnover. For a business focused on long-term operational consistency, this can be a significant advantage. Additionally, wages and general operating costs in Arequipa are typically lower than in the capital.

Key Educational Institutions

TECSUP is a leading technical institute in Arequipa with a strong reputation for producing high-quality engineering and technology professionals. Its curriculum is well-aligned with the needs of industrial operations, providing a reliable source of candidates who can be trained for the specific requirements of solar module assembly.

Business Implications for a Solar Factory

Advantages: A focused, industrially-experienced labor pool, lower comparative labor costs, and potentially higher employee retention rates.

Challenges: A smaller pool of candidates to draw from demands more targeted recruitment. Logistics and supply chain management may require more detailed planning compared to Lima’s centralized infrastructure.

A Comparative Analysis for Decision-Makers

The choice between Lima and Arequipa involves a trade-off between scale and stability. Here is a summary of the key differences:

| Factor | Lima | Arequipa |

|---|---|---|

| Talent Pool Size | Very Large & Diverse | Moderate & Focused |

| Competition for Labor | High | Moderate |

| Typical Wage Level | Higher | Lower |

| Workforce Stability | Potentially Lower | Potentially Higher |

| Logistical Access | Excellent (Port of Callao) | Good (Proximity to Ports) |

| Key Technical Institutes | SENATI | TECSUP |

Ultimately, a detailed financial model is needed to understand the full impact of these variables on the overall solar panel manufacturing cost. A location with lower wages may offer significant long-term savings that outweigh any initial logistical complexities.

Building a Local Workforce: Beyond Recruitment

Regardless of the chosen city, establishing a successful solar module factory in a new market requires a commitment to in-house training. General technical skills from institutions like SENATI or TECSUP provide an excellent foundation, but the specific demands of solar panel production must be taught on-site.

Based on experience from J.v.G. turnkey projects, a structured internal training program is critical. This program should cover machine-specific operations, quality control protocols like EL image interpretation, and safety procedures. The productivity of any workforce is closely tied to the tools they use, and ensuring they are trained on the right solar production equipment is essential for achieving output and quality targets. This approach is particularly effective in emerging markets where the solar industry is new, allowing a company to cultivate a highly skilled, loyal workforce from the ground up.

Frequently Asked Questions (FAQ)

What specific technical skills are most important for solar module assembly?

The most critical skills include a foundational understanding of electronics, mechanical aptitude for operating automated machinery, and exceptional attention to detail for quality control. The ability to interpret technical diagrams and follow precise process steps is also essential.

Are there government incentives for hiring and training local labor in Peru?

Governments often provide incentives for industrial projects that create local employment. Investors should consult with Peruvian agencies like ProInversión to understand current programs related to workforce development, training grants, or tax benefits tied to job creation.

How long does it typically take to train a new production line operator?

Basic operator training for a specific machine can often be completed within two to four weeks. However, developing a highly proficient quality control technician or maintenance specialist can take several months of continuous, hands-on experience on the production floor.

Does the choice between Lima and Arequipa affect the solar panel manufacturing process itself?

The core solar panel manufacturing process remains identical regardless of location. The facility’s location, however, directly influences related activities such as supply chain logistics, raw material warehousing, workforce scheduling, and the transportation of finished goods.

Conclusion: Making an Informed Decision

The decision between Lima and Arequipa is a strategic one with no single correct answer. Lima offers the advantage of scale, a vast talent pool, and unparalleled logistical convenience. Arequipa presents an opportunity for lower operational costs, a focused industrial workforce, and potentially greater long-term stability.

The optimal choice depends on the investor’s specific priorities, business model, and risk tolerance. An enterprise focused on rapid scaling and complex international logistics would likely favor Lima. A business that prioritizes cost control and operational consistency, however, might find Arequipa more suitable. By carefully weighing these distinct labor market dynamics, an investor can lay a strong foundation for a successful and sustainable solar manufacturing operation in Peru.