Entrepreneurs entering the solar manufacturing industry often focus on production lines and sales projections, treating electricity as a standard, predictable utility. In many high-growth markets, however, the cost and reliability of the power supply can be one of the most significant variables affecting a factory’s long-term profitability and operational stability. An otherwise sound business plan can be undermined by high-cost, fluctuating electricity and frequent production stoppages caused by an unstable grid.

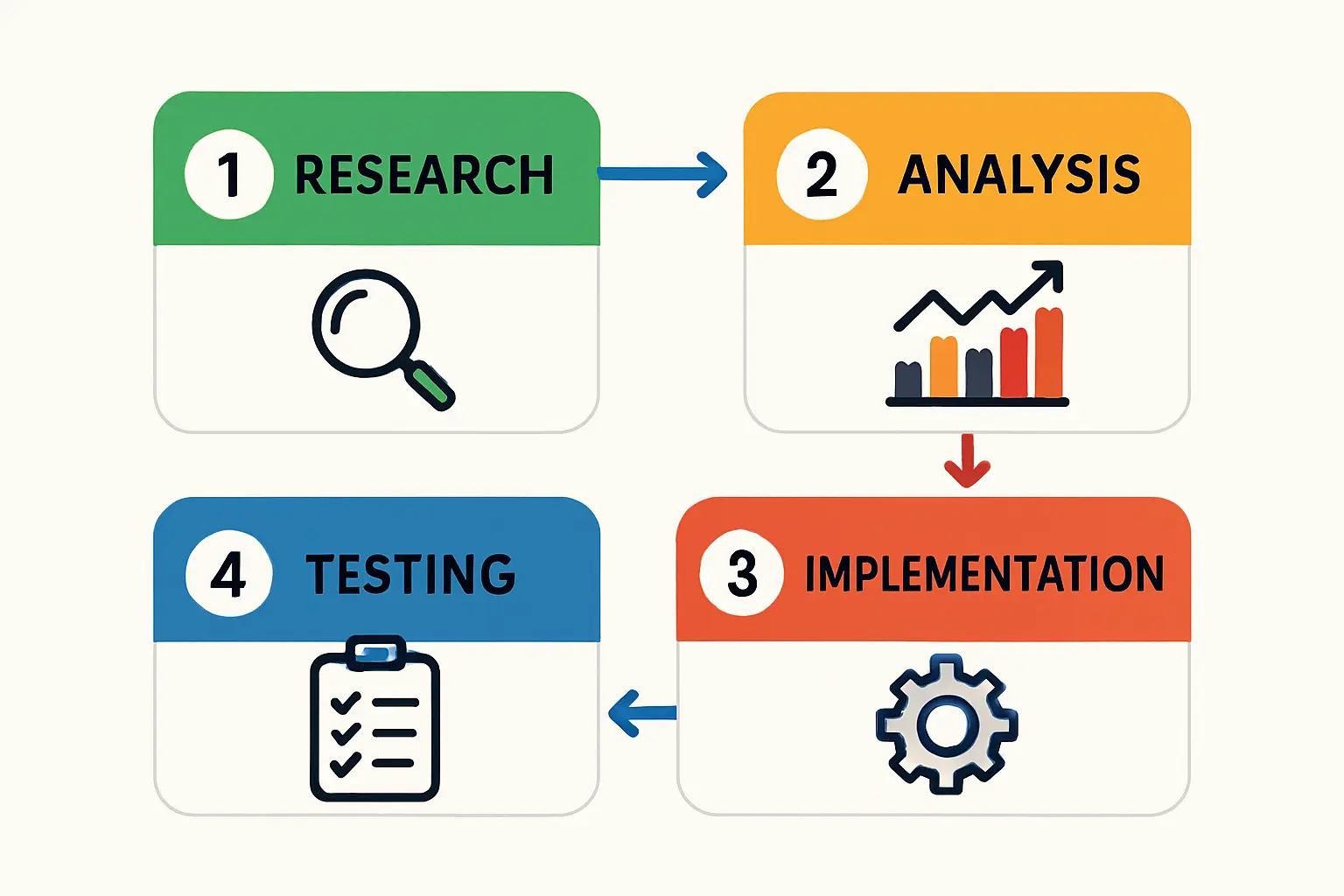

This analysis uses the Philippines as a case study to demonstrate how a thorough assessment of local power infrastructure is not just a preliminary check, but a critical part of planning a new solar module factory. The principles discussed here apply to many emerging markets where rapid industrial growth often outpaces grid development.

The Dual Challenge: High Costs and Low Reliability

For any manufacturing business, energy is a major operational expenditure (OPEX). This cost is magnified for a solar module factory, which relies on energy-intensive machinery like laminators and furnaces. Manufacturers often face a twofold challenge:

-

High Electricity Tariffs: In regions dependent on imported fossil fuels or with limited generation capacity, electricity rates can be significantly higher than the global average. These costs directly erode profit margins and make the final product less competitive.

-

Grid Instability: An unreliable power grid, prone to frequent voltage fluctuations or outright blackouts, poses a direct threat to production. Unplanned downtime can halt assembly lines, spoil raw materials, and damage sensitive solar manufacturing equipment.

Together, these factors create a difficult operational environment that demands attention early in the planning phase.

A Regional Power Analysis: The Case of the Philippines

The Philippines clearly illustrates how power costs and reliability can vary dramatically within a single country, underscoring the importance of location-specific due diligence.

Luzon: High Demand, High Costs

Luzon, the country’s economic hub, is served primarily by Meralco. Electricity rates here often hover around PHP 12/kWh (approx. USD 0.20/kWh). The grid is frequently placed on ‘yellow’ and ‘red’ alerts, especially during the hot, dry season when demand peaks. These alerts signal that operating reserves are thin, increasing the risk of power interruptions for industrial users.

Visayas: The Highest Price Point

In some parts of the Visayas region, costs are even higher. Mactan Electric Company, for example, has posted rates exceeding PHP 16/kWh (approx. USD 0.27/kWh). For a manufacturer, this cost makes it exceptionally difficult to maintain competitive pricing without a mitigation strategy.

Mindanao: A Hydropower Advantage

Mindanao has historically benefited from lower electricity rates—sometimes around PHP 10/kWh (approx. USD 0.17/kWh)—due to its heavy reliance on hydropower. While more affordable, the grid has its own stability challenges, particularly during droughts that affect dam levels.

This regional variance shows that the choice of factory location has a direct, measurable impact on its financial viability.

A Strategic Solution: On-Site Power Generation

For a solar panel manufacturer, the most logical strategy to counter high energy costs and grid instability is to generate its own power. By installing a sizable solar array on the factory’s rooftop and available land, the facility can produce a substantial portion of its own electricity.

This approach, known as self-consumption, transforms a major operational risk into a strategic advantage.

The benefits are immediate and compounding:

- Reduced Operational Costs: Every kilowatt-hour generated on-site is one less purchased from the utility, leading to direct and significant savings.

- Energy Independence: While a grid connection is still needed for 24/7 operations, on-site generation drastically reduces reliance on an unstable grid during daylight hours, when manufacturing is typically at its peak.

- Budgetary Predictability: Self-generation insulates the business from volatile fuel prices and regulatory tariff changes, making financial forecasting more reliable.

Integrating this strategy is fundamental to building a resilient and robust solar panel manufacturing business plan, particularly in markets like the Philippines.

Integrating Power Strategy into Your Factory Plan

Experience from J.v.G. Technology GmbH projects in similar markets shows that the power infrastructure assessment must be part of the initial site selection and feasibility study—not an afterthought. A factory’s power strategy influences its layout, structural engineering for rooftop solar capacity, and long-term financial modeling.

When planning for turnkey solar production lines, it is essential to include the on-site solar power plant as part of the primary project scope. This ensures the energy solution is engineered to meet the specific load profile of the manufacturing equipment, maximizing its efficiency and return on investment.

Frequently Asked Questions (FAQ)

Why are electricity costs so variable in the Philippines?

The costs are driven by a mix of factors, including reliance on imported fossil fuels, the geographical challenges of an archipelago, regional generation capacity, and local distribution costs.

What is a ‘red alert’ on the power grid?

A red alert is a formal notice issued by the grid operator when the power supply cannot meet demand and regulating reserves are depleted. This signals a high probability of rotational blackouts (brownouts) to prevent a total system collapse.

Can a solar factory run 100% on its own solar power?

While a factory can generate much of its daytime energy, running 100% off-grid is generally impractical for large industrial operations. Manufacturing processes often run 24/7, requiring a stable power source at night. A grid connection remains essential and is often supplemented by on-site battery storage or backup generators for critical systems.

Is this power stability issue unique to the Philippines?

No. This challenge is common across many developing economies in Africa, Southeast Asia, and Latin America. The strategic framework of assessing grid stability and planning for on-site generation is a crucial piece of due diligence for any investor considering manufacturing in these regions.

Conclusion: Turning a Liability into an Asset

For entrepreneurs looking to build a solar module factory, the local power grid is more than an outlet on the wall—it is a critical business variable. By proactively assessing utility costs and grid stability and integrating on-site solar generation into the core business model, a potential liability becomes a significant competitive advantage. This foresight ensures greater operational resilience, lower production costs, and a more sustainable, profitable enterprise for the long term.