When business leaders consider where to establish a new manufacturing facility, the conversation often centers on machinery, capital, and supply chains. Yet, a critical factor that determines the long-term success of an operation is the availability and quality of its human capital.

For entrepreneurs looking to start a solar factory, the Philippines presents a compelling, though nuanced, labor market. While not traditionally a hub for photovoltaic (PV) manufacturing, the country’s workforce has a unique combination of foundational strengths that, with the right strategy, can be developed into a significant competitive advantage.

This guide examines the Filipino labor landscape for technical roles, outlines typical wage structures, and explores how to build a world-class manufacturing team by leveraging local educational institutions.

The Philippine Labor Landscape: A Primer for Investors

At first glance, the Philippines offers a highly attractive environment for establishing a technical workforce. The country boasts one of the highest literacy rates in Asia, consistently above 97%. This high level of basic education ensures that new employees can readily understand technical manuals, process documentation, and safety protocols—a fundamental requirement for any modern manufacturing plant.

The Philippines is also the world’s third-largest English-speaking nation. This proficiency removes major communication barriers, simplifying training by international experts and ensuring seamless integration with global management standards and client communications.

These factors contribute to a general labor pool characterized by:

- High Literacy: Facilitates rapid learning and comprehension of complex procedures.

- Widespread English Proficiency: Eases collaboration with foreign engineers, trainers, and management.

- Strong Cultural Adaptability: The workforce is known for its ability to adapt to international business practices.

These foundational elements create fertile ground for developing the specialized skills required in solar module manufacturing.

Assessing the Technical Talent Pool

While general literacy is important, a solar factory requires a core of technically proficient staff. Each year, the Philippines produces a steady stream of graduates in science, technology, engineering, and mathematics (STEM) fields. Government data indicates that universities and colleges turn out tens of thousands of engineering and technology graduates annually, providing a deep talent pool for recruitment.

This means that finding candidates with degrees in Mechanical, Electrical, and Industrial Engineering is generally straightforward. These individuals have the essential theoretical knowledge of automation, electrical circuits, and production processes that form the backbone of a solar module assembly line.

The key distinction, however, is that while these graduates are technically competent, they are rarely solar-specific experts. Very few local university programs offer specialized curricula in photovoltaic manufacturing. An investor’s strategy, then, should not be to find ready-made solar experts, but to create them through a structured, intensive training program. This is a common and entirely manageable scenario in emerging solar markets, provided there is proper planning.

The Role of TESDA and Vocational Training

Beyond university graduates, the Philippines has a robust system for vocational and technical training through the Technical Education and Skills Development Authority (TESDA). This government agency manages and supervises technical education and skills development nationwide, offering a wide range of accredited programs, from basic electronics and welding to more advanced courses in automation and mechatronics.

For a new solar factory, TESDA offers two key strategic opportunities:

-

Hiring Graduates: TESDA-certified technicians provide a reliable source of skilled workers for operator and maintenance roles. They bring hands-on experience with industrial equipment and a practical understanding of workplace safety.

-

Developing Custom Programs: Companies can collaborate with TESDA or private training centers to develop training modules specific to solar panel manufacturing. This proactive approach ensures a steady pipeline of talent trained on the exact machinery and processes used in the factory. This model has been successfully implemented in other industries entering the Philippines, such as electronics and automotive assembly.

Wage Structures and Operational Costs

Labor costs are a critical component of any investor’s business model. The investment required for a solar factory extends beyond machinery to include operational expenditures, and salaries are a major part of that budget.

The wage structure in the Philippines is highly competitive compared to Western nations and even regional manufacturing hubs like China. Entry-level and skilled technical workers can be hired for salaries significantly lower than those in Europe or North America, and they remain competitive with wages in more established Asian manufacturing centers.

University-educated engineers and supervisors command higher salaries but are still cost-effective on a global scale, allowing a factory to build a strong technical leadership team without incurring prohibitive overhead. This favorable wage environment frees up resources for comprehensive training and development, which ultimately leads to a higher-quality, more efficient workforce.

Our experience at J.v.G. Technology GmbH with turnkey projects globally confirms that a well-trained, cost-effective team is a cornerstone of a plant’s long-term profitability.

Building a Competent Team: A Practical Approach

The successful launch of a solar module factory in the Philippines hinges on a clear-eyed strategy for workforce development. This process involves more than just recruitment—it is a systematic program of training and skill transfer.

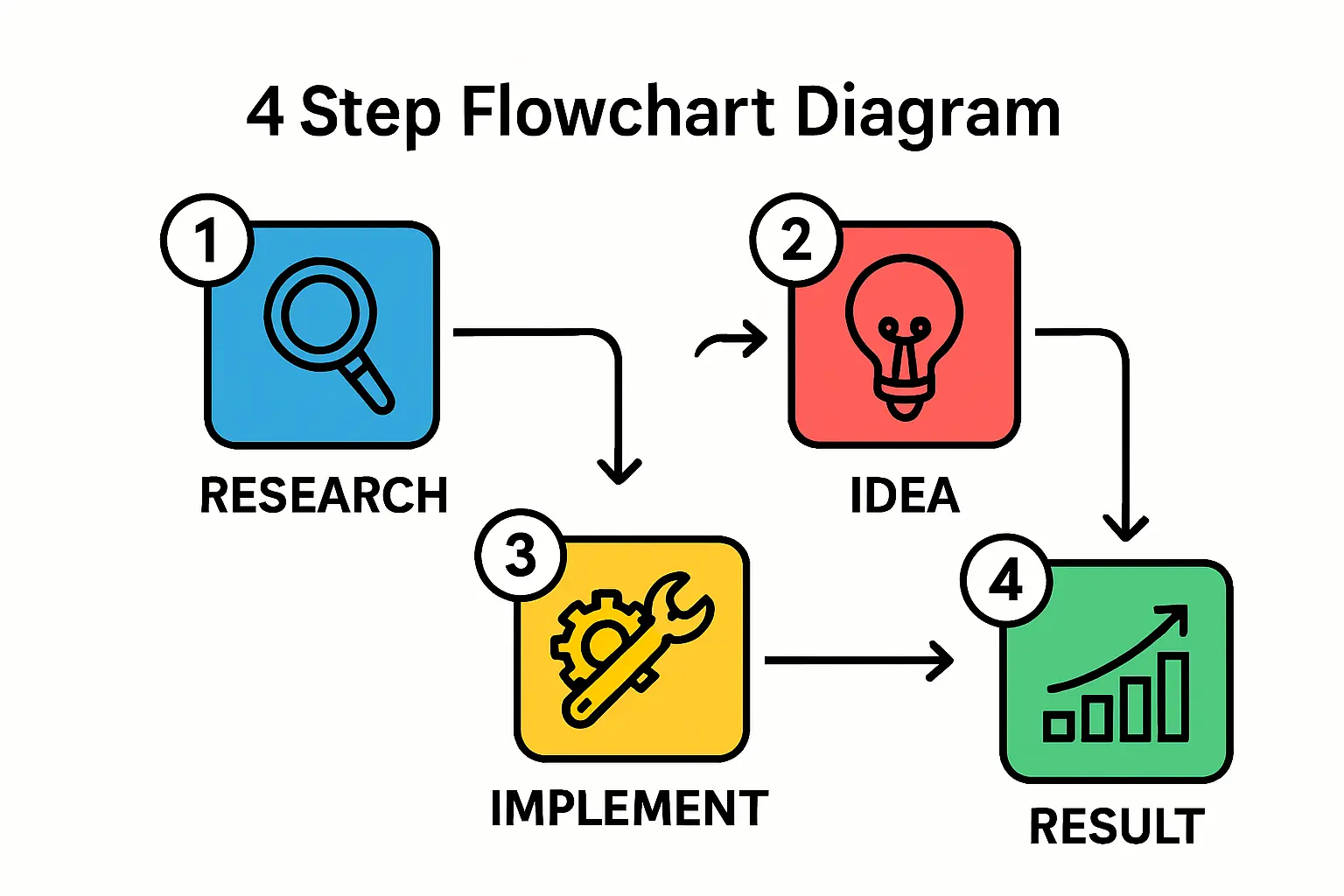

A typical strategy involves these steps:

-

Hire for Foundation: Recruit engineers and technicians with strong fundamentals in electrical and mechanical systems, not necessarily for prior solar experience.

-

Core Team Training: Send a small, core team of key engineers and supervisors abroad for intensive training at a machine supplier’s facility or a reference factory.

-

On-Site Skill Transfer: This core team, alongside experts from the equipment supplier, then leads on-site training for all other operators and technicians as the machinery is installed and commissioned.

This ‘train-the-trainer’ model is highly effective. It not only ensures that knowledge is transferred correctly but also builds a sense of ownership and expertise within the local team from day one. When investing in a turnkey production line, this comprehensive operator and maintenance training is typically an integral part of the service package, de-risking the critical start-up phase for the investor.

Frequently Asked Questions (FAQ)

-

Do I need to hire technicians with prior experience in solar manufacturing?

No, it is not essential. While prior experience is an asset, it is rare in markets new to PV manufacturing. A more effective strategy is to hire candidates with strong foundational skills in electronics, mechanics, or automation and provide them with specialized, machine-specific training. -

How long does it take to train a new production team?

A typical training program for a new solar module factory takes between four and eight weeks. This includes initial classroom instruction followed by extensive hands-on training during the installation and commissioning of the production line. A core team may undergo a slightly longer, more intensive program. -

Is English proficiency sufficient for technical training, or are local translators needed?

Given the high level of English proficiency in the Philippines, especially among those with technical or university education, training can almost always be conducted effectively in English. This significantly simplifies the process and reduces the risk of miscommunication. -

What are the key roles to hire first when setting up a new factory?

The first key hires should be the Plant Manager, a Production Engineer, and a Maintenance Engineer. This core team can then be involved in the subsequent hiring of supervisors and operators, ensuring they have a deep understanding of the personnel they will be managing.