Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

A nation’s economic future is often shaped by a handful of strategic decisions—investments that not only generate revenue but also create entire ecosystems of innovation, employment, and self-sufficiency. For Qatar, as it pursues its landmark Vision 2030, the transition to sustainable energy is one of those pivotal moments. While investing in solar farms is a crucial first step, the larger strategic opportunity lies in controlling the technology itself: manufacturing the high-performance solar modules that will power the region for decades to come.

This proposal outlines a blueprint for establishing a gigawatt-scale solar module production hub in Qatar. This plan is designed to create more than just a factory; it aims to build a national champion—a technological leader that aligns perfectly with the economic diversification and knowledge-based goals of Qatar Vision 2030. This is an industrial project with a clear strategic purpose for the nation.

The Strategic Imperative: Why Qatar is Positioned for Solar Leadership

The viability of a major industrial project depends on the convergence of policy, demand, and infrastructure. For solar manufacturing in Qatar, these elements are not just present; they are uniquely aligned, creating a powerful competitive advantage.

First, guaranteed domestic demand provides a foundational off-take market. Qatar’s plan to install 5 GW of solar capacity by 2035 creates a predictable, large-scale customer base that de-risks the initial investment. A national manufacturing champion would be the natural supplier for these critical state-led energy projects.

Second, world-class industrial and logistics infrastructure is already in place. Industrial zones offer a ready foundation for construction, while access to low-cost energy significantly lowers operational costs. More importantly, Qatar’s position as a global logistics hub, with facilities like Hamad Port and an extensive air cargo network, transforms what could be a supply chain challenge into a strategic asset for both importing raw materials and exporting finished goods.

Finally, this initiative directly serves the core pillars of Qatar Vision 2030. It fosters economic diversification away from hydrocarbons, develops a knowledge-based economy by building expertise in advanced manufacturing, and stimulates private sector growth. This is a tangible step toward building a sustainable and competitive economy for the future.

A Phased Blueprint for Gigawatt-Scale Production

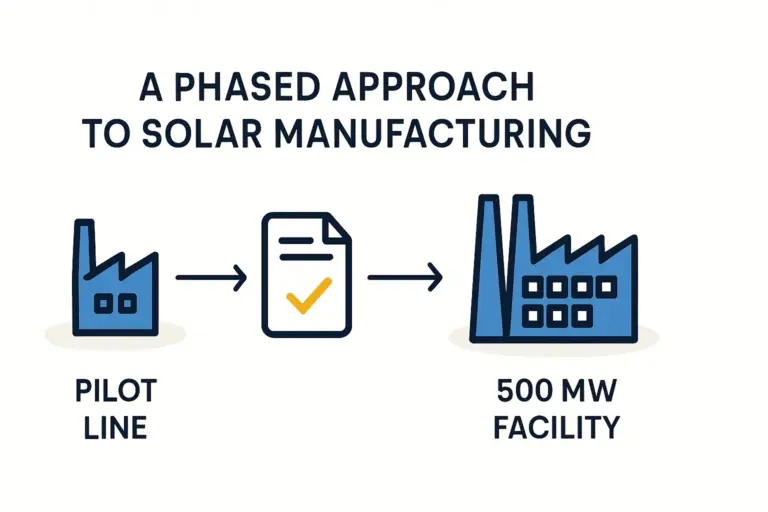

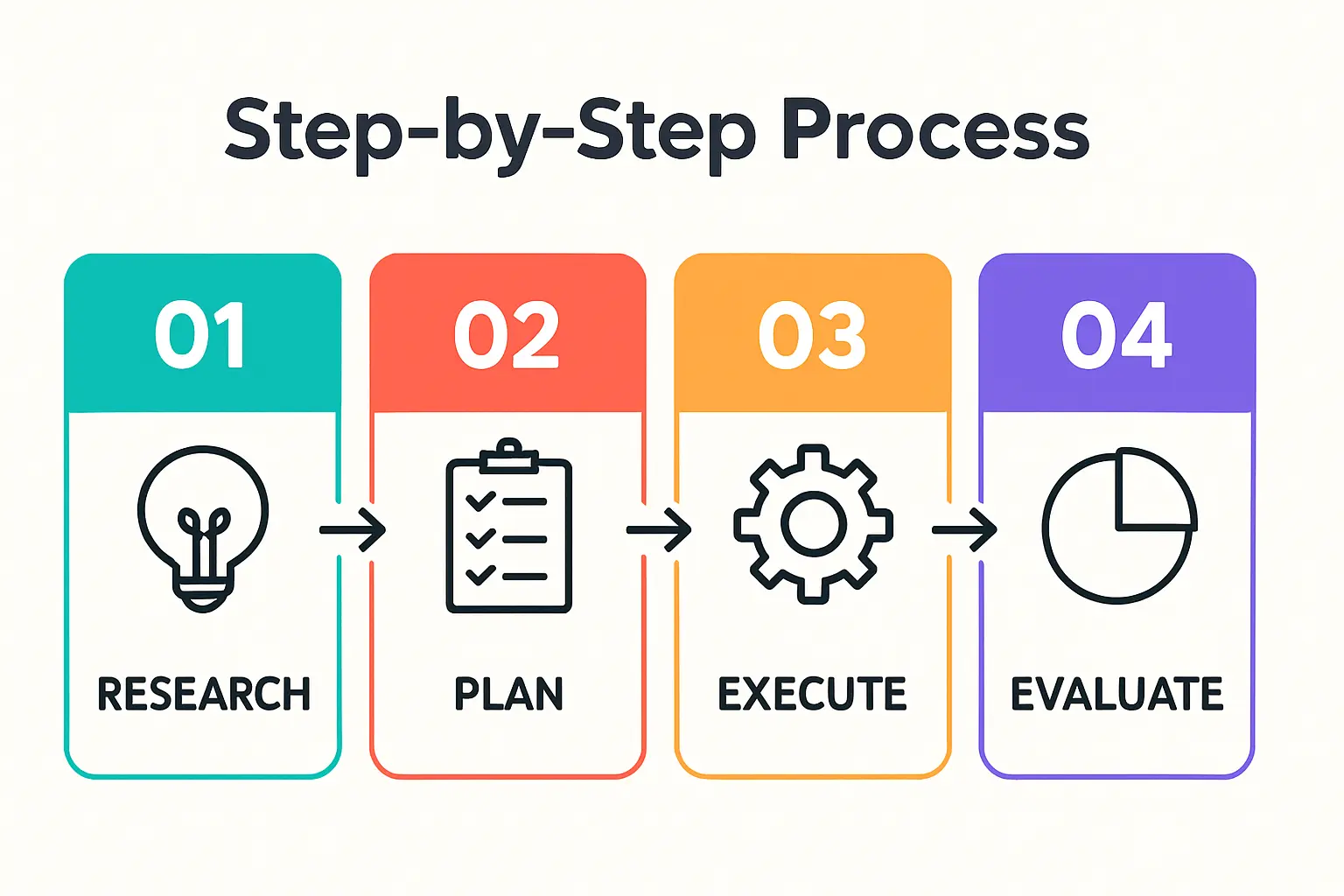

A project of this magnitude requires a prudent, phased approach to manage capital, mitigate risk, and methodically build capabilities. A three-phase expansion plan allows the enterprise to scale alongside market demand and operational expertise. This staged investment model, based on experience gained from European PV manufacturers’ turnkey projects, has proven highly effective.

Phase 1: The 500 MW Foundation

The initial phase focuses on establishing a highly efficient 500 MW production line. The primary goal is to serve Qatar’s domestic projects, master the [Link 2: The Complete Guide to Solar Module Manufacturing Machines], and secure all necessary [Link 3: How to Secure Solar Module Certifications for Global Markets]. This phase builds the operational bedrock, trains the core technical workforce, and establishes the brand’s reputation for quality within the local market.

Phase 2: Scaling to 1 GW and Regional Export

Once the initial line is running at peak efficiency and quality standards are proven, the facility will expand to a cumulative 1 GW capacity. This phase introduces higher levels of automation and leverages Qatar’s logistical advantages to begin exporting to the burgeoning MENA market, which is projected to install over 20 GW of solar capacity annually by 2030.

Phase 3: Achieving 2 GW+ National Champion Status

The final phase scales production to 2 GW or more, cementing the company’s status as a regional leader. Investment at this stage will focus on vertical integration, establishing a dedicated R&D facility to adapt and innovate on existing technologies, and solidifying a global brand presence. The enterprise becomes a true technology company, not just a manufacturer.

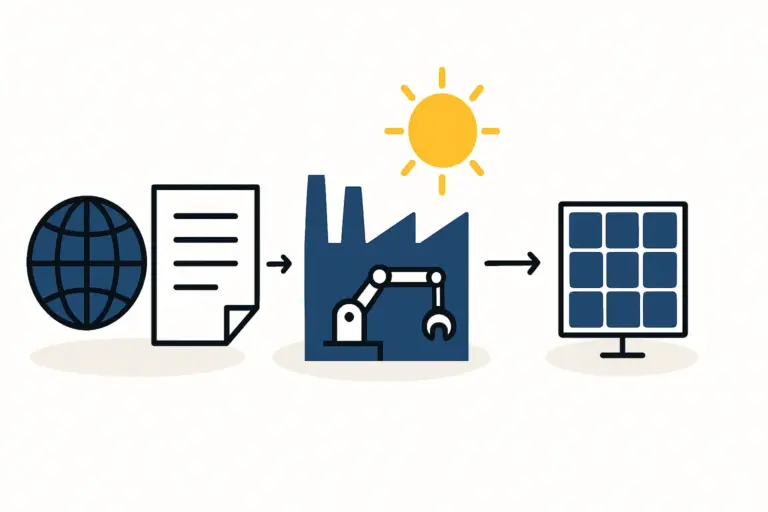

Integrating into the Global Supply Chain from a Position of Strength

A common concern for new entrants is dependency on the global supply chain for raw materials like solar cells, glass, and aluminum frames. However, Qatar’s strategic location and superior logistics infrastructure transform this potential challenge into a distinct competitive advantage.

Hamad Port provides efficient, cost-effective access to suppliers across Asia and Europe. This allows the facility to source high-quality materials globally without the shipping bottlenecks that can hinder other locations, ensuring production remains on schedule and on budget.

For exports, this same logistical prowess allows finished modules to be shipped efficiently to high-growth markets across the MENA region and beyond, making ‘Made in Qatar’ a competitive and reliable choice for international developers.

The Technology Cornerstone: Licensing DESERT+ for Unmatched Performance

Standard solar modules, often designed for temperate European climates, can suffer accelerated degradation and reduced performance in the harsh environmental conditions of the Gulf. The combination of high ambient temperatures, intense UV radiation, humidity, and abrasive sand requires a specialized solution.

This is where a strategic technology partnership becomes critical. Through a licensing agreement with a proven engineering firm like an EU PV factory turnkey supplier, a Qatari manufacturer can immediately access over 30 years of German engineering expertise. The proprietary DESERT+ technology is specifically designed for these conditions.

A DESERT+ [Link 1: What is a Solar Module? A Guide for Business Leaders] incorporates several key enhancements:

-

Heat-Resistant Components: Specialized encapsulants and backsheets that withstand extreme temperatures without premature aging.

-

Reinforced Frames: Anodized aluminum frames and robust junction boxes that resist corrosion from humidity and sand.

-

Specialized Coatings: Anti-reflective and anti-soiling glass coatings that maximize light absorption and reduce the impact of dust accumulation.

By producing a module engineered for its home environment, the Qatari national champion can offer a demonstrably superior product with a longer lifespan and higher energy yield, creating an immediate and sustainable competitive advantage.

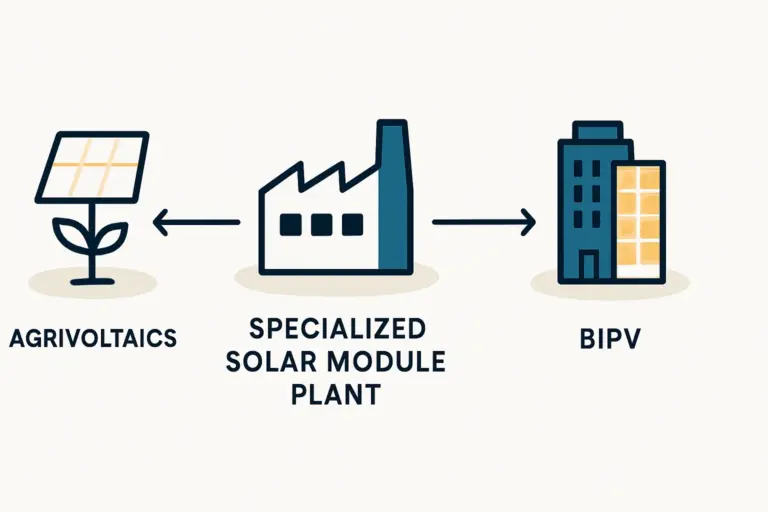

Economic and Strategic Impact Beyond Manufacturing

The establishment of a GW-scale solar factory transcends a simple financial return on investment. Its strategic value includes:

-

Energy Security: Strengthening national autonomy by reducing reliance on foreign technology for critical energy infrastructure.

-

High-Skill Job Creation: Generating hundreds of direct and thousands of indirect jobs for engineers, technicians, and logistics professionals.

-

Technology Transfer: Fostering a domestic talent pool with expertise in advanced renewable energy manufacturing.

-

Export Diversification: Establishing a new, high-value export product that contributes directly to the goals of Vision 2030.

Frequently Asked Questions for Prospective Investors

What is the typical investment requirement for a 500 MW setup?

While costs vary based on building specifications and equipment choices, a turnkey 500 MW line typically requires a significant capital investment. A detailed business plan is essential to outline specific costs for machinery, construction, and operational ramp-up.

How long does it take to get a factory operational?

With a structured [Link 4: Turnkey Solar Factory Setup: A Phased Approach], a new facility can move from groundbreaking to producing its first certified modules in approximately 12 to 18 months, depending on construction timelines and equipment lead times.

Where would the raw materials come from?

The global supply chain for solar components is well-established. Key materials like solar cells, glass, aluminum, and polymers would initially be imported from top-tier suppliers in Asia and Europe, leveraging Qatar’s excellent port facilities.

How important are international certifications?

International certifications are critical. Securing [Link 3: international certifications] such as those from IEC and TÜV is non-negotiable for selling to large-scale utility projects, both domestically and internationally. This process should be planned from day one.

The Path Forward: From Vision to Execution

Establishing a gigawatt-scale solar manufacturing facility is a bold and complex undertaking, yet it represents one of the most compelling industrial opportunities in Qatar today. It is an investment in the nation’s infrastructure, its talent, and a sustainable economic future.

The journey from concept to a fully operational, profitable enterprise requires meticulous planning, proven technology, and expert guidance. By leveraging a phased investment model, securing superior desert-specific technology, and capitalizing on the nation’s inherent logistical strengths, Qatar can build more than a factory—it can create a national champion that will lead the region’s energy transition for generations to come.

Download the National Champion Solar Manufacturing Case Study [PDF]

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.