Many entrepreneurs entering the solar industry see recruiting skilled technical labor as a major initial hurdle. They often assume that a viable location for a new factory must already have a deep pool of photovoltaic experts.

However, an extensive industrial history in other sectors can provide a more valuable foundation than many realize. The key lies not in finding pre-trained solar technicians, but in identifying a workforce with transferable industrial skills and implementing a structured training program to bridge the knowledge gap.

This article outlines a strategic framework for assessing and developing technical labor for solar module production, using Russia’s industrial hubs as a case study. The principles discussed here apply to any entrepreneur evaluating a region with a strong manufacturing heritage for a new solar venture.

The Untapped Potential of Legacy Industrial Cities

Recent research on Russia’s economic landscape identifies over 300 ‘monotowns’—cities historically centered around a single industry, such as metallurgy, machine building, or chemical production. While some of these regions face economic challenges, they offer a crucial asset for new high-tech industries: a deeply ingrained culture of industrial work and a population with fundamental technical skills.

For an investor planning to establish a solar module factory, these areas represent a strategic opportunity. Instead of competing for a small number of experienced PV technicians in established markets, they can draw from a broader pool of candidates who understand production discipline, quality control, and the operation of complex machinery. The challenge, then, shifts from one of scarcity to one of focused training.

Identifying Promising Regions for Recruitment

The most promising locations are those with a history in industries that require precision and process control. Cities like Tolyatti, with its background in automotive manufacturing, or the steel centers of Cherepovets and Magnitogorsk, are home to a workforce accustomed to the rigors of a modern production environment. These workers possess transferable skills in automation, process monitoring, and adherence to precise technical specifications.

When evaluating potential sites, an analysis of the local industrial base provides critical clues. A history in electronics assembly, automotive component manufacturing, or precision engineering points to a labor pool that can be rapidly upskilled for the specific demands of solar module assembly.

Bridging the Skills Gap: From Traditional Industry to Solar Technology

While a background in heavy industry is advantageous, it is no substitute for the specific knowledge required in photovoltaics. The goal is to build upon this existing foundation with targeted training for specialized roles within the solar factory.

Key positions in a typical production line include:

-

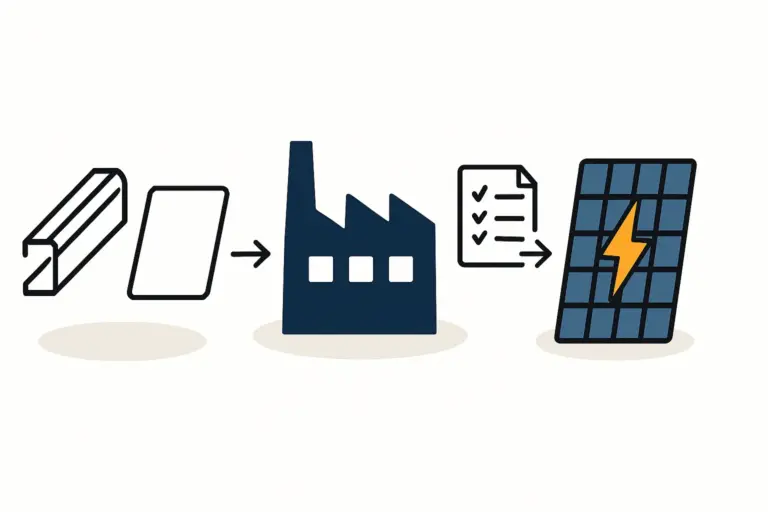

Stringer Operator: Operates the automated machine that solders solar cells together into strings. This role requires high attention to detail and the ability to monitor a sensitive, high-speed process.

-

Laminator Technician: Manages the lamination process, where module components are bonded together under heat and pressure. This demands an understanding of material properties and precise control of machine parameters.

-

Quality Control Inspector: Conducts visual inspections and electrical tests (e.g., using a sun simulator) to ensure each module meets international standards.

For a worker moving from an automotive assembly line to a solar stringer operator, for example, the transition is less about learning manufacturing from scratch and more about adapting existing skills to new materials and a different solar module manufacturing process.

Designing an Effective Training Program

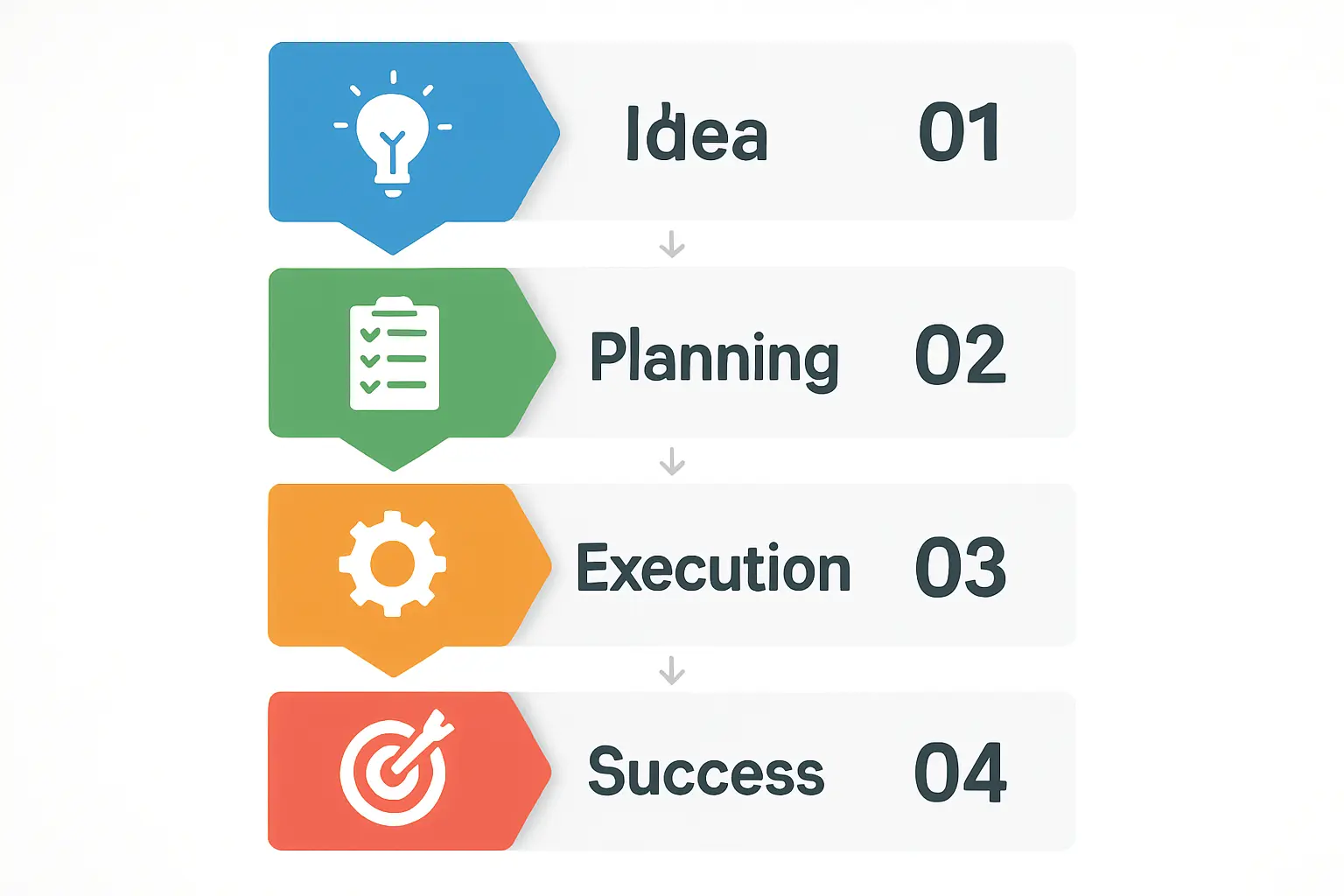

A successful upskilling program is systematic, combining theoretical knowledge with practical, hands-on experience. Experience from J.v.G. Technology GmbH turnkey projects shows that a structured four-to-six-week training program is typically sufficient to bring a team with a relevant industrial background to operational readiness.

A comprehensive program is best structured in three phases:

Phase 1: Foundational PV Knowledge

This classroom-based phase covers the fundamentals of solar cell technology, module construction, material handling, and critical safety protocols. The goal is to provide the ‘why’ behind the manufacturing steps.

Phase 2: Hands-On Machine Training

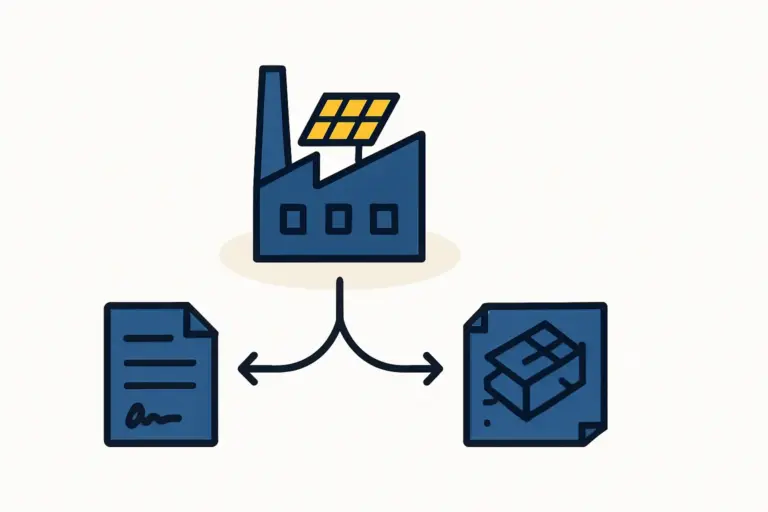

Under the supervision of experienced engineers, trainees learn to operate, calibrate, and maintain the specific equipment on the production line. This is the most critical phase, where theory is put into practice. For clients investing in a complete turnkey solar production line, this on-site training by the equipment supplier’s engineers is an integral part of the commissioning process.

Phase 3: Quality Control and Process Refinement

The final phase focuses on teaching operators to identify potential defects, understand the criteria for quality assurance, and contribute to the ongoing optimization of the production workflow.

Financial and Strategic Considerations

Investing in a local training program offers significant advantages over relocating a large team of external experts. This approach is often more cost-effective in the long run, fosters local community engagement, and builds a sustainable, self-sufficient operational team.

In regions actively seeking economic diversification, government incentives or partnerships with local technical colleges may also be available to support such training initiatives. This human capital strategy should be a core component of the initial business plan and the overall solar factory investment calculation, as a well-trained team is essential for achieving production targets and ensuring product quality.

Frequently Asked Questions (FAQ)

What kind of industrial background is most suitable for solar module manufacturing?

Experience in electronics assembly, automotive manufacturing, textiles, or any field involving automated production lines and stringent quality control provides an ideal foundation. The key attributes are discipline, attention to detail, and an aptitude for technology.

How long does it take to train a new operator for a specific machine like a stringer?

For an individual with a relevant industrial background, focused training on a specific machine can take two to four weeks to become proficient. Full competence and troubleshooting skills typically develop over the first few months of production.

Is it necessary to hire foreign experts to run the factory?

It is common to have a small team of external experts (often provided by the line supplier) on-site during the installation, commissioning, and initial ramp-up phases. Their primary role is to train the local leadership and core technical team, who then become self-sufficient in running day-to-day operations.

What is the typical team size for a small-scale (e.g., 50 MW) solar factory?

A semi-automated 50 MW production line typically requires approximately 25 to 30 employees per shift, including operators, technicians, quality control personnel, and logistics staff.

Ultimately, the availability of a skilled workforce shouldn’t be seen as a prerequisite, but as the manageable outcome of a well-executed plan. By strategically selecting regions with a solid industrial heritage and implementing a robust training program, an entrepreneur can build a highly capable team and establish a successful solar manufacturing operation, even in a market without an established solar industry. Understanding this labor dynamic is a critical first step in planning an entry into the sector.