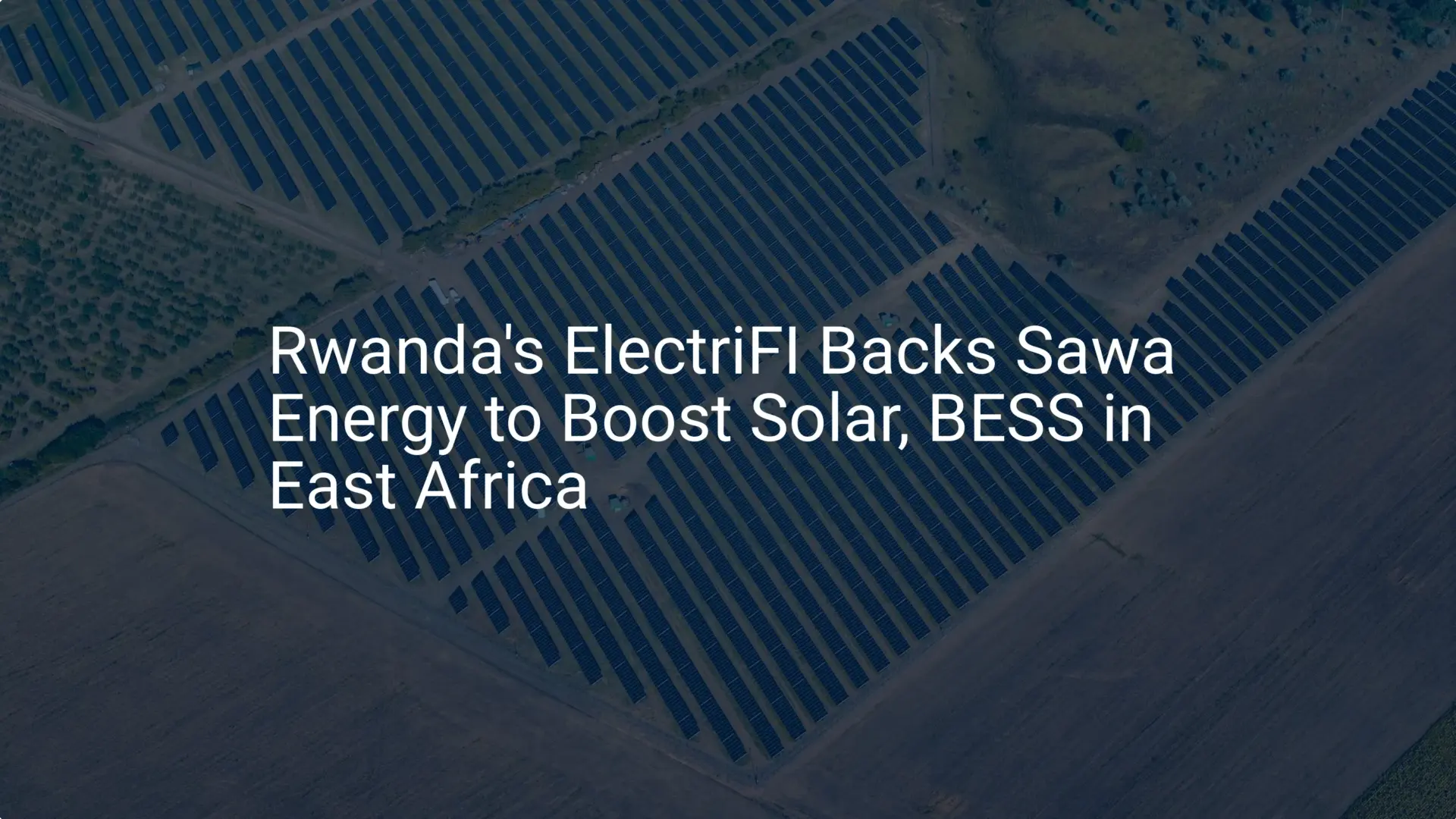

Rwanda’s 36MW Blueprint: Unlocking a Guaranteed Market for Solar Manufacturing

National development plans can seem like high-level policy documents, full of ambitious targets and long-term goals. For a discerning investor, however, they can also serve as a detailed blueprint for market demand.

Rwanda’s National Electrification Plan (NEP) is a prime example. It doesn’t just outline a vision for universal energy access; it presents a clear, data-driven case for establishing local solar panel manufacturing to meet a predictable and substantial need.

This analysis delves into the NEP’s specific targets to quantify the opportunity for investors eyeing Rwanda’s renewable energy sector, showing how national policy translates directly into tangible demand for locally produced solar modules.

Understanding Rwanda’s National Electrification Plan (NEP)

The cornerstone of Rwanda’s energy strategy is achieving 100% electricity access for all households. Recognizing the economic and logistical challenges of extending the national grid to every corner of the country, the government has adopted a pragmatic, two-pronged approach:

On-Grid Connections: Targeting 52% of households to be connected to the main electrical grid. This typically involves extending grid infrastructure to more densely populated areas.

Off-Grid Solutions: Targeting the remaining 48% of households with standalone systems, primarily solar home systems (SHS). This is a cost-effective and rapid method for electrifying rural and remote communities.

This dual strategy is not merely a technical choice; it is an economic one. For many rural households, the cost of grid extension is prohibitive. Off-grid solar provides a faster, more affordable path to modern energy, creating a distinct and significant market segment.

Calculating the Off-Grid Market Opportunity

The most direct, calculable demand for a local solar module factory comes from the NEP’s off-grid targets. The government’s own figures provide the data needed to build a reliable forecast.

The calculation is straightforward:

-

Households to be Connected: The plan aims to provide access to approximately 1.5 million new households.

-

Off-Grid Segment: 48% of these new connections are designated for off-grid solutions.

1,500,000 households * 48% = 720,000 households -

Typical System Size: The average solar home system required for basic lighting and phone charging is around 50 watts-peak (Wp).

-

Total Market Demand: Multiplying the number of households by the average system size reveals the total required solar panel capacity.

720,000 households * 50 Wp/household = 36,000,000 Wp

This translates to a baseline market demand of 36 Megawatts-peak (MWp), coming solely from the off-grid portion of the National Electrification Plan. For a new manufacturing facility, this represents a predictable, multi-year pipeline of orders.

This 36 MWp figure provides a solid foundation for a business case, allowing an entrepreneur to model production capacity, revenue, and the overall investment required for a solar factory.

The On-Grid Component: A Source of Sustained Demand

While the off-grid market is defined by a high volume of small systems, the 52% on-grid target creates a different yet equally important source of demand. As Rwanda works to strengthen and decarbonize its national grid, solar power plays a critical role.

This demand materializes in several ways:

-

Utility-Scale Solar Farms: Large-scale projects feeding directly into the national grid require thousands of solar panels.

-

Commercial & Industrial (C&I) Installations: Businesses are increasingly turning to solar to reduce operating costs and ensure a stable power supply.

-

Mini-Grids: In larger villages not yet connected to the main grid, solar-powered mini-grids serve as a key transitional technology.

A local manufacturing plant is uniquely positioned to supply these projects. A domestic production facility offers significant advantages, such as meeting government tender requirements that often prioritize locally sourced components.

Government Incentives and the Business Environment

The Rwandan government actively supports investment in its renewable energy sector. This goes beyond policy targets and includes tangible financial incentives that directly improve the business case for a local manufacturing operation.

Key measures include:

-

Tax Exemptions: Imported solar system components, including the raw materials needed for manufacturing, are exempt from Value-Added Tax (VAT) and import duties. This significantly lowers both initial setup costs and ongoing operational expenses.

-

Local Content Preference: Government-led projects often give preference to ‘Made in Rwanda’ products, providing a competitive edge against foreign imports.

These incentives are embedded within Rwanda’s long-term ‘Vision 2050’, which aims to transform the nation into an upper-middle-income country. Local manufacturing aligns perfectly with this vision by creating skilled jobs, fostering industrial capacity, and reducing reliance on imports.

Why Local Production Holds a Strategic Advantage

In a globalized market, a local manufacturer in Rwanda has several strategic advantages over international competitors.

-

Supply Chain Resilience: A local factory avoids the long lead times, high shipping costs, and currency volatility associated with importing finished panels. This ensures a more reliable supply for critical national projects.

-

Product Customization: A domestic producer can design and manufacture modules specifically tailored to the local market—for example, smaller, more robust panels for solar home systems in rural areas.

-

Enhanced Trust and Service: A local presence enables easier after-sales support, warranty fulfillment, and technical assistance, building greater trust with customers and government partners. Experience from J.v.G. Technology turnkey projects in other emerging markets consistently shows that a local operational base is a key factor in long-term success.

Frequently Asked Questions (FAQ)

What is a typical starter factory size for a market like Rwanda?

For a market with a quantifiable demand of 36 MWp over several years, a starter factory with an annual production capacity of 20 MW to 50 MW is a common and viable entry point. This allows for scalability as both on-grid and off-grid markets mature.

Is it difficult to find trained labor for a solar factory in Rwanda?

While the specialized workforce is still developing, the country has a young and motivated labor pool. A standard project setup includes a comprehensive training program, often led by experienced engineers, to transfer the necessary technical skills to the local team.

How can a local factory compete on price with large international manufacturers?

Competition is not based on price alone. A local factory competes by offering superior logistics, eliminating international shipping costs, avoiding import duties on finished goods, providing faster delivery, and aligning with government incentives that favor local production.

What is the first step to properly assess this opportunity?

The essential first step is to develop a detailed feasibility study and a professional solar business plan. This document validates market assumptions, outlines production costs, projects financial returns, and serves as the foundational document for securing financing and investment.

Conclusion: From National Policy to Business Opportunity

Rwanda’s National Electrification Plan is more than a statement of intent; it is a clear market signal. The government’s well-defined targets for on-grid and off-grid connections create a predictable, multi-year demand for solar modules. This data greatly reduces the guesswork typically associated with market entry, providing a solid foundation for investment.

For an entrepreneur, the challenge lies in translating this policy-driven opportunity into an operational reality. By leveraging government support, focusing on the strategic advantages of local production, and starting with a robust business plan, an investor can build a successful manufacturing enterprise that delivers both commercial returns and significant national impact.