Financial Modeling: Estimating Operational Expenditures for a Solar Factory in Saint Vincent and the Grenadines

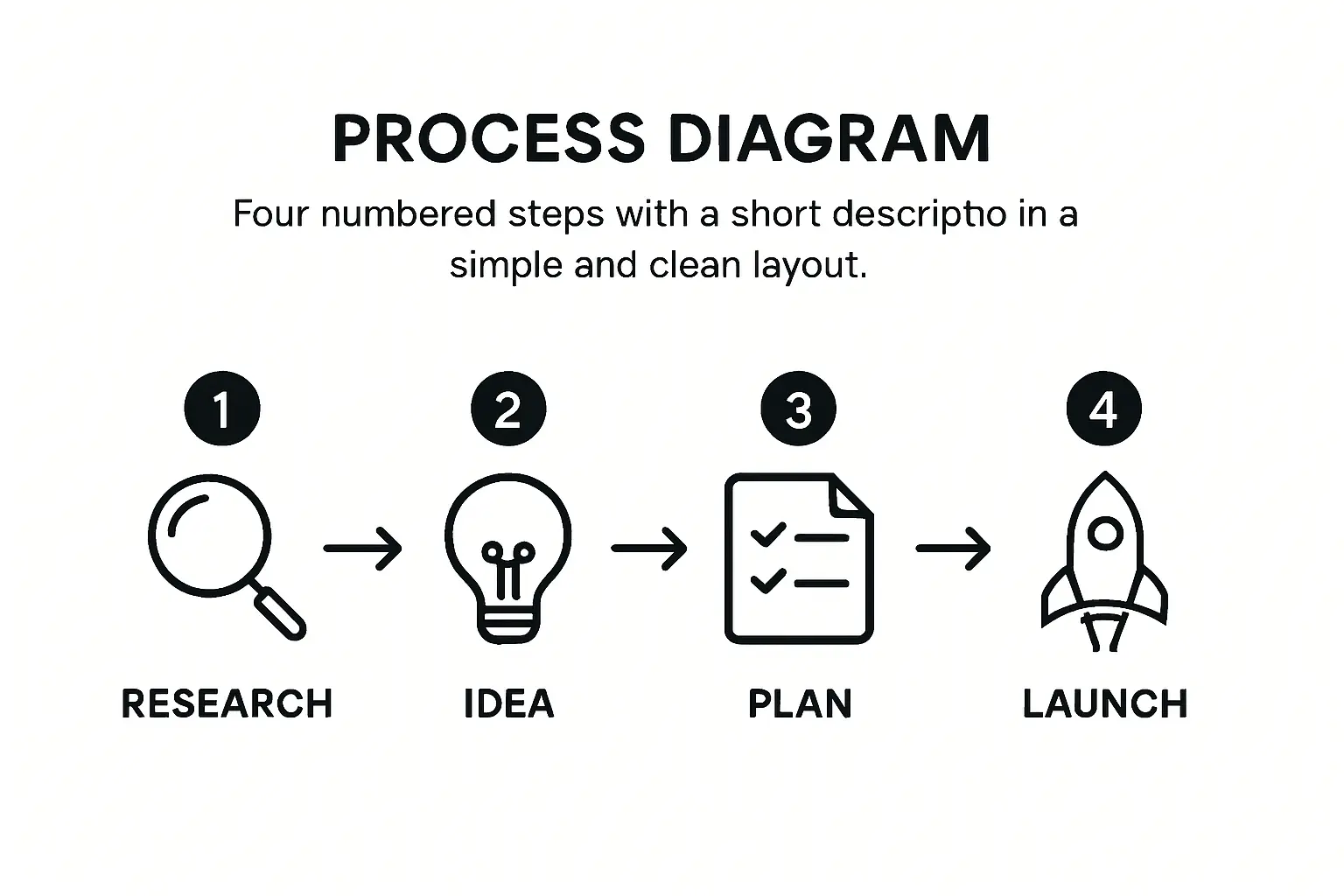

Launching a new manufacturing facility is an exciting milestone. The machinery is installed, the building is complete, and the initial team is in place. But long-term profitability isn’t determined by the grand opening—it hinges on the careful management of ongoing costs. While many entrepreneurs focus heavily on upfront capital, the true measure of a sustainable business lies in mastering its Operational Expenditures (OpEx).

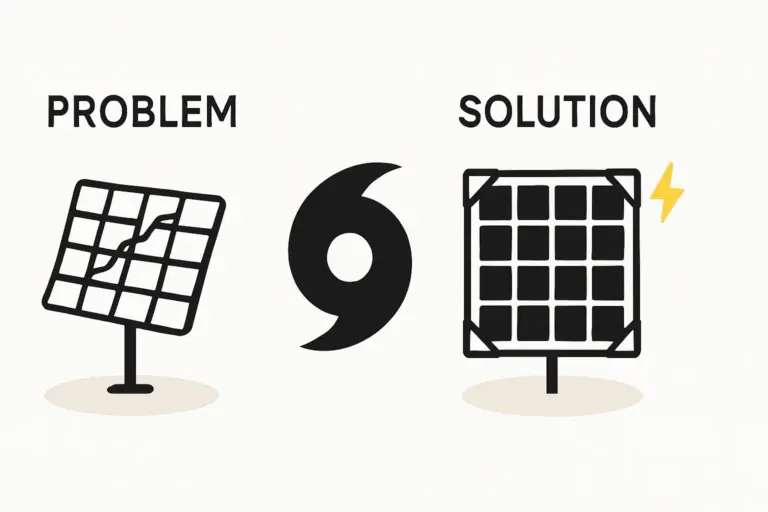

Nowhere is this truer than in a market with the potential of Saint Vincent and the Grenadines (SVG). The nation aims to generate 80% of its energy from renewable sources by 2030, yet currently relies on imported fossil fuels for over 95% of its power. This gap makes the opportunity for local solar module manufacturing clear. Success, however, depends on a financial model that accurately reflects the unique economic and logistical landscape of the islands.

Understanding OpEx goes beyond simple accounting; it’s about building a resilient operational strategy. It means anticipating recurring costs—from local wages to inter-island logistics—long after the initial capital for machinery and setup has been spent. This guide provides a framework for estimating these crucial expenditures for a small to medium-sized solar factory in SVG.

Core Components of Your Factory’s OpEx

Operational expenditures are the day-to-day costs of running the business. A clear understanding and categorization of these costs are fundamental to accurate financial forecasting and to setting prices for your finished solar modules. The primary OpEx categories for a solar assembly plant include labor, utilities, raw materials, logistics, maintenance, and administrative overhead.

Labor Costs: Your Most Valuable Asset

Your workforce is the engine of your factory. In SVG, labor costs are a significant component of OpEx and must be planned with precision. A typical semi-automated solar module factory of 20-50 MW capacity may employ 25 to 35 people across various roles.

These roles typically fall into two main categories:

-

Skilled Labor: This includes line supervisors, quality control technicians, and maintenance engineers who require specialized training. Based on the local market in SVG, wages for skilled personnel range from USD 10 to USD 15 per hour.

-

Unskilled or Semi-Skilled Labor: This group comprises the majority of the workforce, including line operators responsible for specific stages of the assembly process. The average wage for these roles in SVG is approximately USD 4 to USD 6 per hour.

For a factory with five skilled technicians and 20 line operators on a standard shift, the monthly wage bill is a primary cost driver. Factoring in social contributions and potential overtime is essential for a realistic budget. Investing in training is also a key consideration, as a well-trained staff is crucial for mastering manufacturing processes and ensuring high product quality.

Utilities and Energy Consumption

In an island nation dependent on imported fuel, utility costs—especially electricity—are a critical OpEx variable. The electricity tariff in SVG can range from USD 0.25 to USD 0.30 per kWh, substantially higher than in many larger industrial economies.

For a solar factory, the major power consumers are the laminator, stringer machines, and climate control (HVAC) systems. An inefficient workflow or poor insulation can lead to significant energy waste, highlighting the importance of a well-designed facility. Thoughtful factory layout planning can directly contribute to lower monthly utility bills.

A strategic advantage for a solar manufacturer in this environment is the ability to use its own product. Installing a solar array on the factory roof can drastically reduce electricity costs, insulate the business from grid price volatility, and serve as a powerful demonstration of the product’s value.

Logistics and Supply Chain Management in an Archipelago

Saint Vincent and the Grenadines is an archipelago, which introduces unique logistical complexities that must be factored into your OpEx. Nearly all raw materials—solar cells, glass, aluminum frames, EVA foil—will be imported.

Key Logistical Costs:

-

Inbound Logistics: Materials will likely arrive at the main port in Kingstown. Costs include ocean freight, port handling fees, customs duties (though exemptions may apply for green technology), and inland transportation to your factory site.

-

Inter-Island Distribution: If your market extends to the Grenadine islands, the cost of transporting finished modules via ferry or other marine transport must be calculated. This ‘last-mile’ cost can be significant and will affect your final product pricing.

Maintenance, Spares, and Consumables

To ensure consistent output and quality, a proactive maintenance schedule is non-negotiable. The tropical climate of SVG, with its high humidity and salt-laced air, can accelerate wear on machinery if not managed properly.

Your OpEx budget must include:

-

Preventative Maintenance: Regular servicing of key machines like stringers and laminators.

-

Spare Parts Inventory: Keeping critical spare parts on-site is essential to prevent costly production shutdowns while waiting for a replacement to be shipped internationally.

-

Consumables: These are items consumed during the production process, such as cleaning agents, specialized machinery lubricants, and personal protective equipment (PPE) for staff.

Administrative and Compliance Overheads

These are the costs of running the business beyond the factory floor. They are often stable but must not be overlooked.

-

Factory Lease or Rent: A significant and predictable monthly expense.

-

Insurance: Coverage for the facility, equipment, and liability is essential.

-

Salaries: Administrative staff, including management, finance, and sales personnel.

-

Compliance and Certification: Maintaining product and factory standards involves ongoing costs, including periodic audits and testing. This is crucial for securing the certifications that open export markets or qualify for government projects. The SVG government’s focus on green technology may present opportunities, but compliance with its standards will be mandatory.

Frequently Asked Questions (FAQ)

How much of a project’s total budget should be allocated to first-year OpEx?

A common business planning guideline is to have at least six to twelve months of projected operational expenditures available as working capital. This ensures the business can function smoothly as it ramps up production and sales, covering costs before revenue becomes consistent.

Can a solar factory realistically reduce its utility costs by using its own panels?

Absolutely. This is a primary strategic advantage. By installing a solar PV system on its own roof, a factory can significantly lower its electricity bill—a major OpEx component in SVG. It also enhances the company’s green credentials and provides a real-world showcase for its products.

How do SVG’s import duties affect raw material costs?

The Government of Saint Vincent and the Grenadines has historically offered tax incentives and import duty exemptions for equipment and materials related to renewable energy projects. Investors should engage with Invest SVG or the relevant ministry to confirm current policies, as these incentives can substantially reduce the cost of imported raw materials.

What is the most commonly underestimated operational cost for new solar factories?

Many new entrepreneurs underestimate the cost of maintaining a sufficient inventory of spare parts for critical machinery. A single machine failure without a spare part on hand can halt the entire production line for weeks, leading to a loss of revenue far greater than the cost of the part itself.

Conclusion: From Financial Model to Sustainable Operation

Building a solar module factory in Saint Vincent and the Grenadines is a venture with immense potential to support the nation’s energy independence and create local value. However, translating that potential into a profitable reality requires moving beyond initial investment figures to create a granular, realistic, and locally adapted model of operational expenditures.

By carefully forecasting costs for labor, utilities, logistics, and maintenance, an entrepreneur can build a resilient business prepared for the unique challenges and opportunities of the Caribbean market. A well-structured business plan, informed by these local conditions, is the true foundation for a successful and sustainable manufacturing operation.