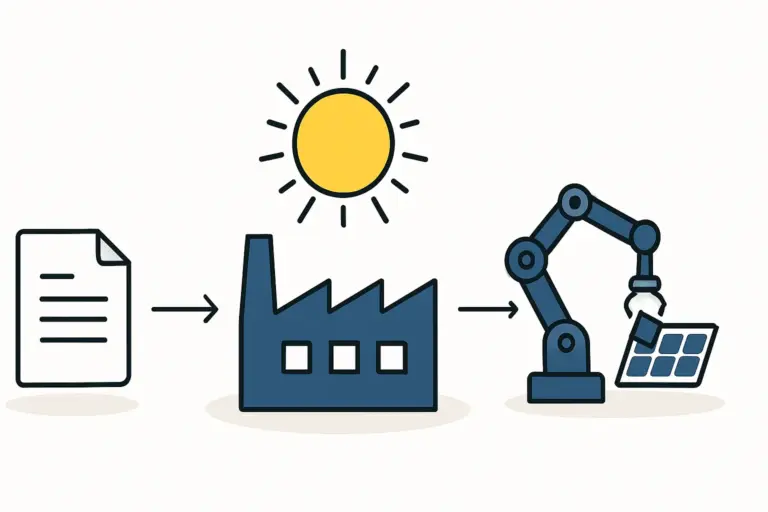

Even with a perfectly engineered business plan, a state-of-the-art facility, and a robust financial model, a new solar module factory’s timeline and budget can be jeopardized by one often-underestimated factor: logistics. Transporting multi-ton, high-precision manufacturing equipment from Germany or China into a Saudi industrial city—and later shipping finished solar modules to international markets—is a critical operational challenge.

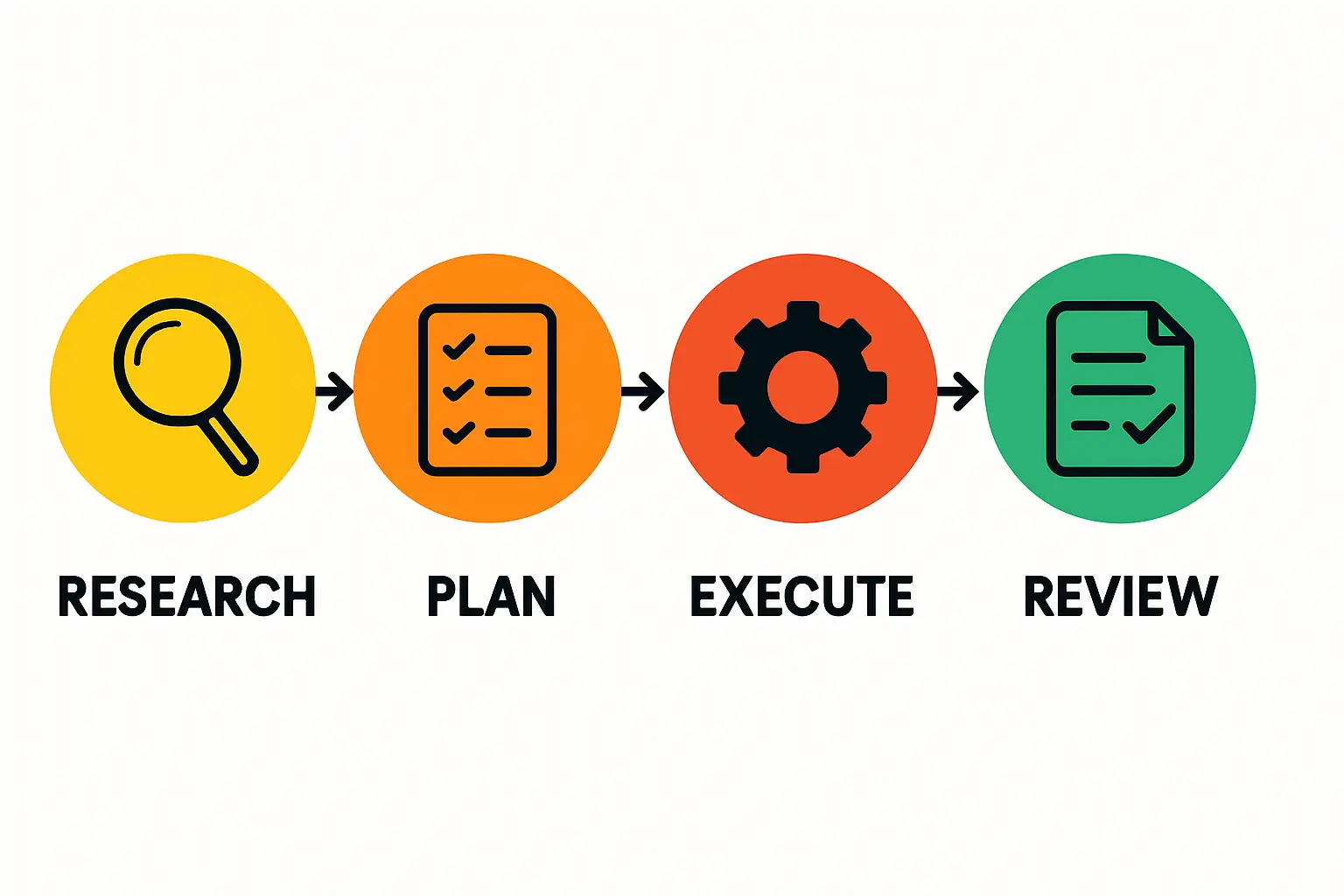

This article offers a practical overview of the logistical framework in Saudi Arabia, focusing on key considerations for importing production machinery and exporting finished products through its principal seaports. For any investor planning to enter the Kingdom’s growing solar manufacturing sector, understanding this landscape is a crucial first step.

Saudi Arabia’s Strategic Position in Global Logistics

The Kingdom of Saudi Arabia’s commitment to becoming a global logistics hub is a core pillar of Vision 2030. This is not merely an ambition on paper; it is backed by massive investment in infrastructure and process optimization. For a prospective solar manufacturer, this national strategy translates into a highly favorable operational environment.

The country’s recent jump from 55th to 38th in the World Bank’s Logistics Performance Index is a testament to these improvements, particularly in customs clearance efficiency and the quality of trade infrastructure.

At the heart of this logistical network are two world-class ports:

-

Jeddah Islamic Port (JIP): On the Red Sea, JIP is one of the busiest ports in the world and the primary gateway for cargo from Europe, North America, and Africa. Its strategic position on a major east-west trade route makes it ideal for both importing European machinery and exporting modules to Western markets.

-

King Abdulaziz Port (KAP) in Dammam: Situated on the Arabian Gulf, KAP is the largest port in the Gulf region. It is the main entry point for goods from Asia and the Indian subcontinent, which makes it the logical choice for sourcing equipment from countries like China. It is also perfectly positioned for exporting to neighboring GCC countries and Asian markets.

These ports are not just entry and exit points; they are integrated logistical hubs connected by an expanding rail and road network that enables efficient transit to major industrial cities.

Phase 1: Importing Your Production Machinery

The first major logistical test for any new solar factory is the successful importation of the production line itself. This equipment is heavy, sensitive, and high-value, requiring meticulous planning.

Navigating Customs and Documentation

A common pitfall for new importers is incomplete or incorrect documentation. Customs delays often stem not from infrastructure but from administrative errors. The key to a smooth process is preparation. Essential documents typically include:

- Commercial Invoice: A detailed invoice from the machinery supplier.

- Certificate of Origin: Authenticating the country where the equipment was manufactured.

- Bill of Lading / Airway Bill: The contract between the cargo owner and the shipping line.

- SASO Certificate of Conformity: Most goods imported into Saudi Arabia must comply with standards set by the Saudi Standards, Metrology and Quality Organization (SASO), managed through the online SABER platform.

Engaging a reputable, licensed customs broker is not an optional expense; it is a critical investment. An experienced broker can ensure all documentation is correctly prepared and submitted in advance, heading off potential issues and accelerating the clearance process.

Handling and Inland Transportation

Once your machinery clears customs, the next step is moving it from the port to your factory. Solar manufacturing equipment, such as laminators and stringers, can weigh several tons and requires specialized handling.

This process involves coordinating with freight forwarding companies experienced in heavy-lift cargo. They will arrange for the necessary cranes, flat-bed trucks, and personnel to ensure the equipment is loaded and transported safely. While the quality of Saudi Arabia’s highway network connecting Dammam, Riyadh, and Jeddah is a significant advantage, final-mile delivery to the factory site still requires careful planning. Understanding the investment requirements for a solar factory helps in allocating a sufficient budget for these crucial logistical services.

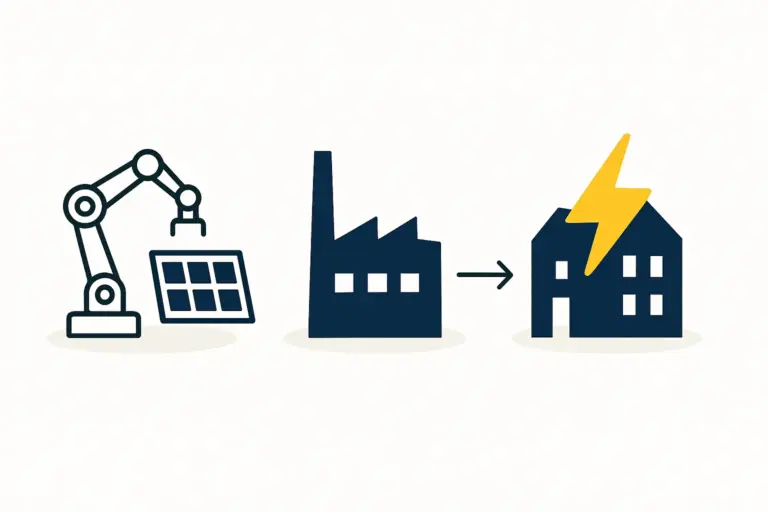

Phase 2: Exporting Finished Solar Modules

Once your factory is operational, the logistical focus shifts from inbound equipment to outbound products. The efficiency of your export process directly impacts your profitability and ability to compete in international markets.

Packaging, Containerization, and Freight

Solar modules, particularly modern designs, are robust but require specific packaging to prevent damage during transit. They are typically stacked vertically on custom pallets, shrink-wrapped, and corner-protected before being loaded into standard 20-foot or 40-foot shipping containers.

One of the first key metrics to determine is how many modules can safely fit into each container type. This calculation affects shipping costs per unit and is essential for providing accurate quotes to international buyers. Choosing between different module technologies, such as those discussed in the guide on Glass-Glass vs. Glass-Backsheet Modules, can also have implications for weight and packaging, which in turn influences logistical costs.

Leveraging Port Capabilities for Global Sales

The choice between Jeddah and Dammam for export depends entirely on your target markets.

-

For markets in Europe, Africa, and the Americas: Jeddah Islamic Port offers direct and frequent shipping services, minimizing transit times.

-

For markets in the GCC, India, and East Asia: King Abdulaziz Port in Dammam is the more efficient and cost-effective choice.

Both ports have advanced container terminals with high throughput, reducing vessel waiting times and ensuring your products can be shipped reliably. Many successful export operations are also based in industrial cities or special economic zones, which can offer streamlined export procedures and other incentives.

Frequently Asked Questions (FAQ)

What is the role of a freight forwarder?

A freight forwarder is a logistics specialist who acts as your agent to arrange the transportation of your goods. They do not move the cargo themselves but contract with various carriers—shipping lines, airlines, trucking companies—to manage the entire process, from the factory door to the final destination. Their role is particularly crucial in complex international shipments involving multiple modes of transport and customs clearance.

How long does customs clearance typically take in Saudi Arabia?

Thanks to significant process improvements, customs clearance can be very fast if all documentation is in order. With pre-cleared documentation submitted by a competent broker, cargo can often be released within 24-48 hours of arrival. However, any discrepancies can lead to inspections and delays.

Are there specific certifications required for importing machinery?

Yes, the most critical is the SASO Certificate of Conformity, obtained through the SABER platform. Your machinery supplier must work with an approved conformity assessment body to ensure their equipment meets Saudi standards before it is shipped. Failure to do so will prevent the goods from clearing customs.

Which port is better for my factory, Jeddah or Dammam?

This depends on two main factors:

-

Origin of Machinery: If your equipment is sourced from Europe, Jeddah is often more direct. If it is from China or other parts of Asia, Dammam is the logical choice.

-

Primary Export Markets: If you plan to sell finished modules to Europe or Africa, a location closer to Jeddah is advantageous. For sales within the Gulf or to Asia, proximity to Dammam is preferable.

Planning Your Logistical Success

Logistics should be treated as an integral part of your factory’s design and business strategy, not as an afterthought. The Kingdom of Saudi Arabia offers world-class infrastructure, but leveraging it effectively requires diligent planning and partnership with experienced logistics professionals.

By building relationships with reliable customs brokers and freight forwarders early in the process, entrepreneurs can avoid costly delays and ensure a smooth transition from factory setup to global sales. A comprehensive understanding of logistics is a cornerstone of the complex but rewarding process of how to start a solar module factory. Mastering this aspect ensures your investment is built on a solid, practical foundation.