Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Saudi Arabia’s Vision 2030 is not merely a statement of intent; it is a comprehensive blueprint for economic transformation. Central to this vision is a seismic shift in the Kingdom’s energy landscape, targeting 40 gigawatts (GW) of solar power capacity.

This ambitious goal creates a significant, sustained demand for high-quality solar modules. It presents a unique opportunity for investors and entrepreneurs to establish a local manufacturing presence—one that can directly contribute to and benefit from this national mandate.

A Public-Private Partnership (PPP) offers a structured, de-risked pathway for launching a 250 MW solar panel manufacturing plant. This model aligns the strategic interests of the government with the operational and financial capabilities of a private enterprise, creating a powerful synergy. This article outlines the framework for such a venture, from structuring the partnership to deploying a world-class production line.

Understanding the PPP Model in the Saudi Context

At its core, a Public-Private Partnership is a collaboration between a government entity and a private-sector company to deliver a project or service. In the context of a 250 MW solar factory in Saudi Arabia, the roles are typically distributed as follows:

-

The Public Partner: Often a state-affiliated entity such as the Public Investment Fund (PIF) or the Ministry of Energy, this partner provides strategic support. This support can include long-term offtake agreements for the factory’s output, access to land in designated industrial zones, and help with navigating regulatory approvals.

-

The Private Partner: This is the investor or business consortium providing the capital investment, operational management, and commercial expertise. They are responsible for the day-to-day running of the factory, from supply chain management to staffing and quality control.

-

The Technical Partner: A specialized engineering firm, such as a European industrial solutions provider, provides the manufacturing technology, plant design, and operational know-how. This partner ensures the facility is built to international standards and can produce modules meeting the stringent requirements of utility-scale projects.

The primary advantage of the PPP model is its ability to mitigate market risk. With government support often including guaranteed demand for the panels, the private investor can focus on achieving operational excellence.

Aligning with Saudi Vision 2030 and the National Renewable Energy Program (NREP)

Any major industrial project in the Kingdom must be fundamentally aligned with Vision 2030. A 250 MW solar panel factory is not just an industrial asset; it is a critical piece of infrastructure for achieving the nation’s clean energy goals. The National Renewable Energy Program (NREP), managed by the Ministry of Energy, is the primary mechanism for executing this vision.

Establishing a local manufacturing facility directly supports several key NREP objectives:

- Energy Security: Reducing reliance on imported solar modules.

- Economic Diversification: Building a new, high-tech industrial sector beyond oil and gas.

- Job Creation: Developing a skilled workforce in advanced manufacturing.

The 250 MW scale is strategic, positioning the facility to supply modules for the gigawatt-scale solar farms being developed under the NREP, such as the Sudair and Al Shuaibah projects. This scale makes the factory a significant contributor to the national supply chain.

Navigating Local Content Requirements and Government Incentives

A significant advantage for in-Kingdom manufacturers is the government’s focus on local content. The Local Content and Government Procurement Authority (LCGPA) has established policies that give preference to local suppliers in government tenders. For a solar module factory, this represents a powerful commercial advantage.

By manufacturing locally, the project not only meets but capitalizes on these requirements, making its products highly attractive for state-led utility projects. The government also offers a compelling suite of incentives to encourage such investments:

-

Financial Support: The Saudi Industrial Development Fund (SIDF) provides favorable, long-term loans for industrial projects that align with Vision 2030.

-

Tax Incentives: Projects in certain economic zones may benefit from reduced corporate tax rates and exemptions on customs duties for imported raw materials and machinery.

-

Land Grants: Access to strategically located and subsidized land in industrial cities like NEOM, Jubail, or King Abdullah Economic City simplifies site selection and reduces setup costs.

Successfully navigating this landscape requires a detailed solar panel manufacturing business plan that clearly demonstrates the project’s contribution to local value creation.

Structuring the 250 MW Manufacturing Facility

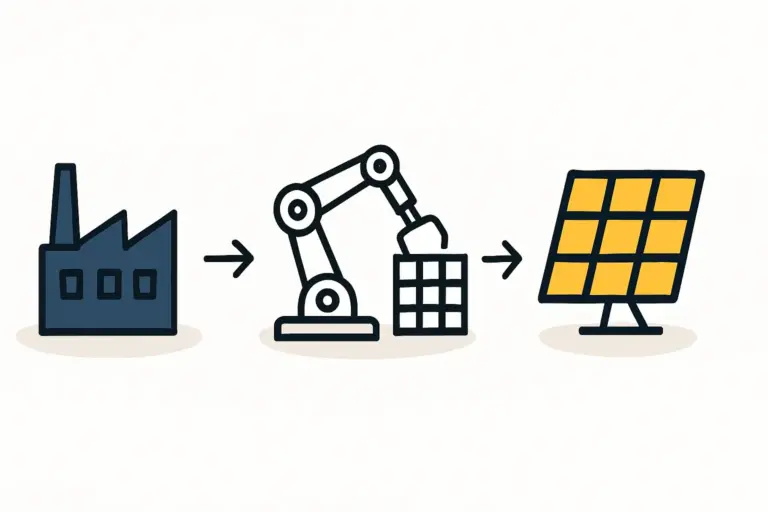

The physical plant is the heart of the venture. A 250 MW facility must be designed for high-volume, automated production, which is where a turnkey solution becomes invaluable. A turnkey approach involves a single technical partner designing and delivering the entire production line, ensuring all solar panel manufacturing machines are integrated and optimized to work together seamlessly.

The process of establishing the factory follows a structured path:

- Feasibility and Planning: Defining the project scope, financial model, and technology selection.

- Engineering and Design: Creating the detailed factory layout, including utilities, cleanroom specifications, and workflow logistics.

- Procurement and Logistics: Sourcing and shipping all manufacturing equipment and components to the site.

- Installation and Commissioning: Assembling the production line and running initial tests to ensure it meets performance specifications.

- Training and Ramp-Up: Training local staff to operate and maintain the equipment, gradually increasing production to full capacity.

Based on experience from J.v.G. turnkey projects, this entire process, from final agreement to the first panel produced, can be completed in under 24 months with proper planning and execution.

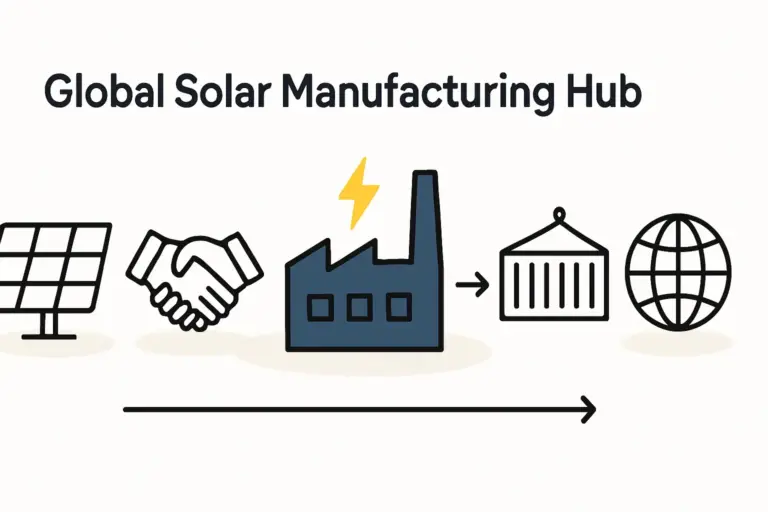

A Phased Approach to Market Entry

While the ultimate goal may be a 250 MW facility, some investors may prefer a phased approach. Starting with a smaller, more manageable capacity is a practical way to build operational experience and establish a market presence.

A 20-50 MW solar panel production line can serve as an excellent starting point, allowing the enterprise to secure initial contracts and refine its processes before scaling up to meet the demand from larger utility projects. This modular approach reduces initial capital outlay and allows the business to grow in step with the market.

Frequently Asked Questions (FAQ)

What is the typical investment for a 250 MW solar factory?

While specific figures depend on technology choices and building costs, the capital expenditure for a highly automated 250 MW turnkey line, including machinery, installation, and training, is a significant industrial investment. A detailed financial model is essential for accurate budgeting.

How long does it take to become operational?

For a 250 MW project, a realistic timeline from project financing confirmation to full-scale production is approximately 18 to 24 months. This includes factory construction, equipment delivery, installation, and the production ramp-up phase.

What are the main technical challenges?

The primary challenges are ensuring consistent quality control at high volume and establishing a reliable supply chain for raw materials such as solar cells, glass, and encapsulants. Partnering with an experienced technical provider is crucial to overcoming these hurdles.

Is prior experience in solar manufacturing necessary for the investor?

No. The turnkey model is specifically designed for new market entrants. The technical partner provides the necessary expertise, training, and operational frameworks. The investor contributes business acumen, local market knowledge, and financial stewardship to the project. Guidance on how to start a solar panel factory is available for those beginning their journey.

Conclusion and Next Steps

The convergence of Saudi Arabia’s Vision 2030, a structured PPP framework, and robust government support has created an unprecedented opportunity for investment in solar panel manufacturing. A 250 MW facility is a strategic asset that aligns commercial goals with national priorities.

By leveraging the PPP model to secure offtake and incentives, and partnering with a proven technical expert to deliver a world-class production line, investors can build a profitable and sustainable business that will power the Kingdom’s future for decades to come.

For business professionals ready to explore this opportunity, the next step is to develop a deeper understanding of the technical and financial requirements. With the right strategy, you can build a cornerstone of Saudi Arabia’s renewable energy future.

Download: Saudi Arabia 250 MW Solar PPP Case Study [PDF]

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.