Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Many successful entrepreneurs in West Africa face a common challenge: high operational costs driven by expensive and unreliable electricity. For businesses in Senegal’s thriving Commercial and Industrial (C&I) sector, this can hinder growth and competitiveness.

While solar energy presents a clear solution, reliance on imported modules often introduces significant logistical and cost complexities. This article outlines a factory plan for entrepreneurs looking to address this gap by producing solar modules locally. It presents a strategic approach for establishing a manufacturing facility tailored to the unique demands of Senegal’s C&I market—one that can transform a national energy challenge into a significant business opportunity.

Understanding the C&I Opportunity in Senegal

Senegal’s commitment to increasing its share of renewable energy to 30% by 2025 has created a favorable environment for solar development. While utility-scale projects have contributed to the nation’s 282 MW of installed solar capacity (as of 2021), the C&I sector is emerging as a powerful engine for future growth.

Businesses are increasingly turning to rooftop solar installations not just for sustainability, but for economic resilience. The primary drivers include:

- High Electricity Tariffs: Self-generation offers a direct path to reducing operational expenditures.

- Grid Instability: On-site solar power provides a reliable energy source, minimizing downtime from grid failures.

- Favorable Government Policies: Initiatives promoting local content incentivize domestic manufacturing, creating a competitive advantage for in-country producers.

A local factory allows an entrepreneur to serve this growing demand directly, reducing import dependency and strengthening the national supply chain.

Key Challenges for Solar Modules in a West African Climate

A common oversight for new entrants is assuming that all solar modules perform equally. The West African climate presents specific environmental challenges that can severely degrade standard panels, leading to underperformance and early failure.

Key factors include:

- High Ambient Temperatures: Extreme heat reduces the efficiency of solar cells, lowering a module’s actual power output. Over time, it can also accelerate material degradation.

- Harmattan Dust: During the dry season, fine dust particles accumulate on module surfaces, blocking sunlight and reducing energy yield. This requires modules that are easy to clean and resistant to abrasion.

- High Humidity: Particularly in coastal areas, high humidity can lead to moisture ingress, causing corrosion and delamination if modules are not properly sealed.

These regional conditions require a product specifically engineered for durability and sustained performance in a challenging environment.

Designing the Right Product: The DESERT+ Module Specification

To effectively serve the Senegalese C&I market, a factory must produce modules designed to overcome the region’s climate challenges. The DESERT+ module technology offers a proven technical specification for this purpose. It is not a brand, but a set of engineering principles focused on durability in hot, arid, and dusty conditions.

Key features of a DESERT+ compliant module include:

- High-Performance Cells with Low-Temperature Coefficients: Minimizes power loss as temperatures rise.

- Specialized Encapsulants and Backsheets: Provide superior protection against moisture and UV radiation, preventing delamination.

- Reinforced, Anti-Reflective Glass: Enhances durability and captures more light, even in dusty conditions.

A module built to these specifications ensures a reliable, long-lasting product—one that delivers real value to C&I clients and builds a strong reputation for quality and performance.

Structuring the Production Facility: A Flexible Factory Plan

For an entrepreneur entering the market, agility is more valuable than sheer scale. A flexible, semi-automated production line with an initial capacity of 25–50 MW per year is an ideal starting point. This approach offers several advantages:

- Adaptability: The line can be configured to produce various module sizes and specifications, allowing the business to respond to different C&I rooftop requirements.

- Lower Initial Investment: A semi-automated setup balances efficiency with capital expenditure, reducing the initial investment required for a solar panel factory.

- Focused Operations: This capacity allows a new enterprise to focus on quality control and market penetration before scaling up.

A typical 25–50 MW facility requires approximately 30–50 employees and a 2,000–3,000 square meter building. The heart of the factory is its manufacturing process, a sequence of steps orchestrated by core machinery whose function dictates the facility’s layout, workflow, and final product quality.

The Implementation Roadmap: From Concept to Commissioning

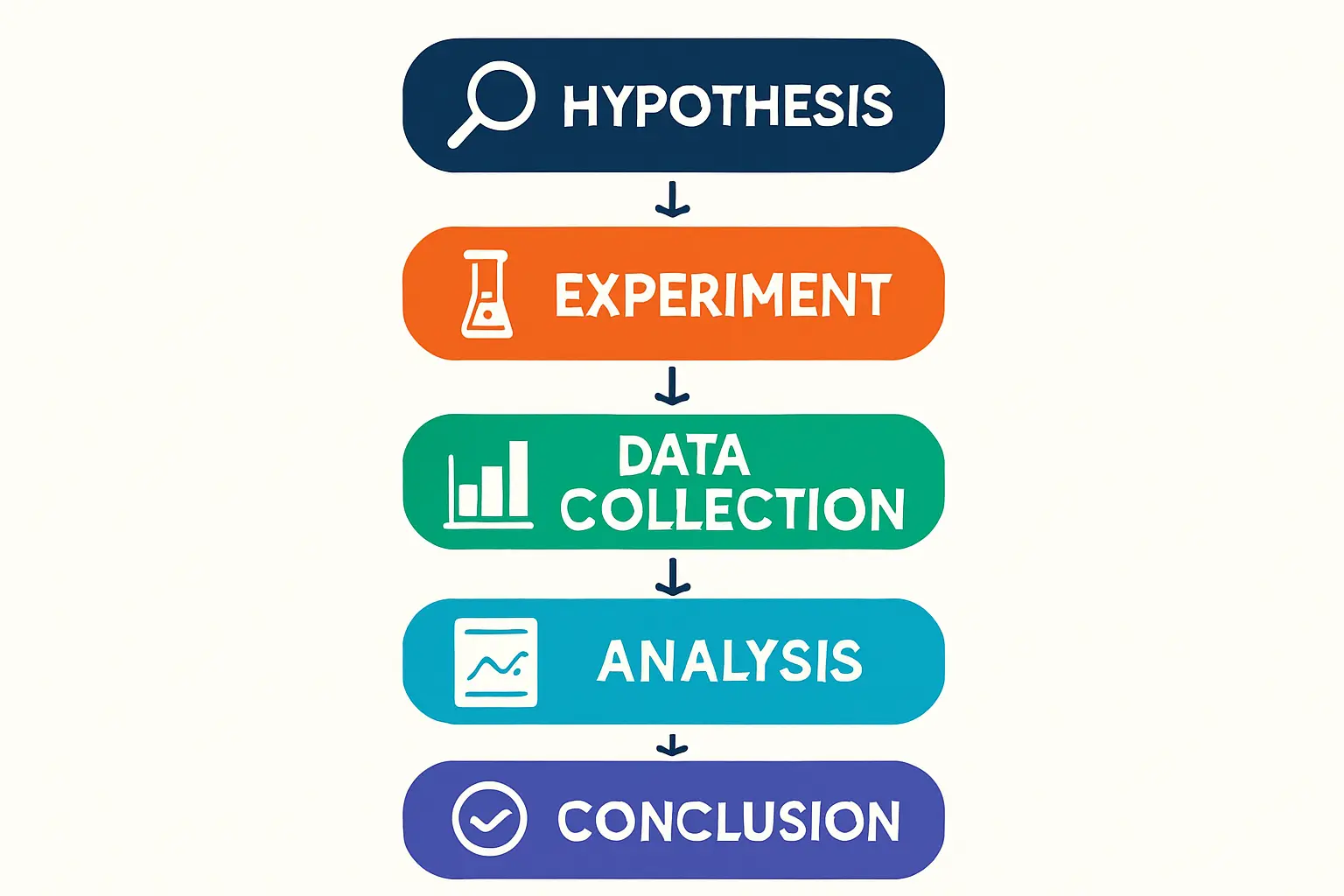

Launching a solar module factory is a complex undertaking that benefits from a structured, phased approach guided by experienced partners. The journey from concept to commissioning can be broken down into clear stages.

- Phase 1: Strategic Planning and Consultation. Before any equipment is ordered, a robust business plan is essential. This phase, often guided by consultants with deep industry expertise, defines the product specifications (e.g., DESERT+), factory layout, financial modeling, and market entry strategy.

- Phase 2: Turnkey Implementation. Once the plan is finalized, an engineering partner manages the execution. This includes procuring and shipping all machinery, overseeing installation, training local staff, and commissioning the production line.

- Phase 3: Operational Support. After commissioning, ongoing support ensures smooth operations, from establishing raw material supply chains to optimizing production efficiency.

This structured process, often delivered as a turnkey production line setup, de-risks the project and enables an entrepreneur without a prior technical background to enter the industry with confidence.

Frequently Asked Questions (FAQ) for New Entrants

What is the typical timeframe to set up a solar module factory?

From final contract to the start of production, a well-managed turnkey project for a 25–50 MW line typically takes between 9 and 12 months. This includes equipment manufacturing, shipping, installation, and commissioning.

Do I need a technical background in photovoltaics to start this business?

No. While technical curiosity is helpful, the most critical requirements are business acumen and investment capacity. A turnkey partner provides the necessary engineering expertise, process knowledge, and operational training for your local team.

How much space is needed for a 25–50 MW factory?

A facility of this size generally requires a building with a total area of 2,000 to 3,000 square meters. This accommodates the production line, raw material storage, finished goods warehousing, and administrative offices.

How are raw materials sourced for production?

Establishing a reliable supply chain is a key component of a turnkey partnership. Your implementation partner helps identify and vet international suppliers for critical components like solar cells, glass, encapsulant (EVA), and aluminum frames, ensuring they meet the required quality standards.

Conclusion: Building Senegal’s Solar Future, Locally

Senegal’s transition to renewable energy presents a significant opportunity for local entrepreneurs. By establishing a specialized solar module factory focused on the C&I sector, a business can meet a critical market need with a high-quality, locally-made product.

Success does not hinge on being a solar expert from day one. It relies on a clear vision, a solid business plan, and collaboration with experienced partners who can manage the technical complexities. With a strategic approach, a new manufacturing enterprise can become a key player in powering Senegal’s economic growth and energy independence.

Download: Senegal Commercial & Industrial Solar Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.