Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Entrepreneurs entering the solar manufacturing industry often face a dilemma: launch a large-scale facility for immediate economies of scale, or start small to minimize initial risk? A large investment carries substantial financial exposure, while a smaller factory may struggle with profitability. A third option, however, offers a strategic alternative—a phased approach that combines the security of a smaller start with a clear roadmap for large-scale success.

This article outlines a phased investment model for a solar panel factory, using a real-world project in Thiès, Senegal, as a case study. Developed through close expert consultation and implemented by a specialized EU engineering partner, this plan illustrates how to build a scalable manufacturing operation, starting with a 30 MW line and expanding to 100 MW..

The Strategic Advantage of a Phased Investment Model

For investors new to photovoltaics, a large, single-phase investment can be daunting. A phased model directly addresses the primary concerns of market entry: high capital expenditure, market uncertainty, and the operational learning curve.

Starting with a manageable 30 MW capacity allows a company to establish its presence, test the regional market, and generate revenue—all while keeping the initial investment at a sensible level. This methodical approach lets the operational team master production processes and build a skilled workforce before undertaking a major expansion. De-risking the project this way is a core component of a sound solar panel manufacturing business plan.

Case Study: A 30 MW Starter Factory in Thiès, Senegal

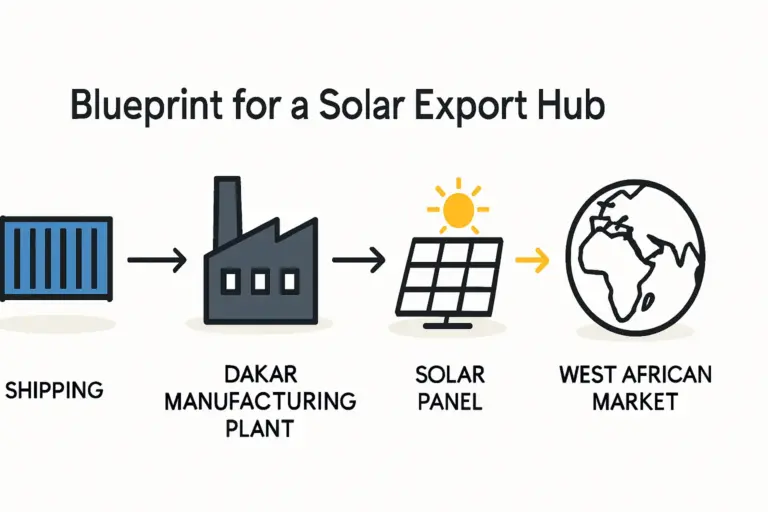

The project in Thiès was conceived to meet West Africa’s growing demand for locally produced solar modules. Its primary objective was to establish a modern manufacturing facility with minimal initial capital outlay but without compromising future growth potential. The solution was a turnkey factory designed in two distinct phases.

Phase 1: Establishing the 30 MW Foundation

The first phase focuses on constructing the complete factory building but equipping it with only the essential machinery for a 30 MW annual production capacity. The key strategic decision is to design and build the physical infrastructure—the building, foundations, and utility connections—to accommodate the final 100 MW capacity from the outset.

3D layout rendering of the initial 30 MW solar factory floor plan, showing key machine placements and open space for future expansion.

With this ‘future-proofing’ approach, the initial equipment occupies only a portion of the factory floor, leaving prepared space for additional lines. This foresight is critical because it eliminates the need for disruptive and expensive civil works during the expansion phase. The initial setup includes all the core machines needed to produce certified, high-quality solar modules, allowing the business to become operational and build its market share quickly.

The Roadmap from 30 MW to 100 MW

With the 30 MW line running, the business can focus on sales, operations, and supply chain management. The expansion to 100 MW is not a speculative leap but a calculated response to demonstrated market demand, funded partly by revenue from the initial phase.

Phase 2: Scaling Production to 100 MW

The transition from 30 MW to 100 MW is primarily a matter of procuring and installing equipment, not a construction project. Since the building and utilities were pre-designed for this capacity, the process is streamlined and efficient. New machinery, such as additional stringers, laminators, and testing equipment, is installed in the reserved floor space.

3D layout rendering of the expanded 100 MW factory, showing the new machinery filling the previously empty space, illustrating the scalability.

This phase allows the business to leverage its experienced core team to train new staff and ensure quality standards are maintained as production volume increases. The established brand presence and sales channels from Phase 1 provide a solid foundation to absorb the increased output.

Key Considerations for a Smooth Expansion

Successful scaling requires careful planning in several areas:

-

Machine Selection: The initial solar panel manufacturing machine set should be chosen with scalability in mind. Opting for modular equipment or technology that integrates well with higher-throughput machines simplifies the expansion.

-

Labor Force Development: The initial team, trained during Phase 1, becomes a valuable asset for training new employees and ensuring a consistent transfer of skills and operational knowledge.

-

Supply Chain Optimization: As production capacity grows, so does the demand for raw materials. The initial phase provides the time needed to develop robust relationships with multiple suppliers, mitigating risks from supply chain disruptions.

Financial Implications of the Phased Approach

The primary benefit of this model is the significant reduction in initial Capital Expenditure (CAPEX). Investors can enter the market with the investment required for a 30 MW line and a 100 MW-ready building, rather than the full cost of a 100 MW turnkey facility.

This de-risked financial structure is often more attractive to banks and investment partners. The subsequent investment for Phase 2 occurs when the business is already operational and has a proven track record, making it easier to secure financing or fund directly from profits. While the total cost over two phases may be slightly higher than a single large-scale installation, the reduced risk, earlier market entry, and improved cash flow present a more compelling business case, particularly in emerging markets.

Frequently Asked Questions (FAQ)

What is the typical timeline for setting up the initial 30 MW phase?

From finalizing the equipment order to the start of production, a timeline of 9 to 12 months is realistic. This includes machine manufacturing, shipping, installation, commissioning, and staff training.

Why not start with a smaller capacity, such as 10 MW?

While technically possible, factories with capacities below 20-30 MW often struggle with economic viability. Overhead costs and the inability to achieve volume discounts on raw materials can make it difficult to compete on price.

Is it more expensive overall to build in phases?

The total capital expenditure may be marginally higher due to two separate installation and commissioning schedules. However, this modest increase is a sound trade-off for mitigating the substantial financial risk of a large, single-phase launch.

What are the main challenges during the expansion phase?

The primary challenges are logistical. Installing new equipment must be managed carefully to avoid disrupting ongoing production from the existing line. Additionally, recruiting and training a larger workforce to the same high standards requires a structured program.

Can this phased investment model be applied in other regions?

Yes. The principles of minimizing initial risk, future-proofing infrastructure, and scaling based on market demand are universally applicable. This model provides a robust framework for starting a solar panel business in any region.

A Blueprint for Sustainable Growth in Solar Manufacturing

The phased investment strategy, as demonstrated by the Thiès project, offers a pragmatic and financially prudent path for entrepreneurs entering the solar manufacturing sector. It lowers the barrier to entry, manages risk effectively, and creates a platform for sustainable, demand-driven growth.

By building a future-proofed facility from day one, investors ensure their business is not limited by its initial size. This foresight transforms the first factory into a scalable asset, ready to expand as the market matures. This structured planning empowers entrepreneurs to confidently build a successful manufacturing enterprise from the ground up.

Download the Thiès Solar Factory Expansion Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.