Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For many entrepreneurs and national planners in Senegal, the country’s abundant sunshine is more than a climate feature—it’s a vast, untapped economic resource. As the national government’s ‘Plan Sénégal Émergent’ (PSE) targets universal electricity access by 2025, the focus on renewable energy is sharper than ever.

Yet, a critical question remains: how can this solar potential be harnessed to directly empower the nation’s most vital economic engine—its agricultural sector? The answer may lie not just in importing solar panels, but in manufacturing them locally. This article outlines a turnkey approach for setting up a solar module factory tailored to the unique needs of Senegalese agribusiness, transforming a national vision into a tangible, profitable, and impactful enterprise.

The Challenge: Why Standard Solar Modules Underperform in Agricultural Applications

Senegal’s agricultural sector, which accounts for approximately 17% of GDP and employs a majority of the workforce, faces a significant barrier to growth: a lack of reliable, affordable energy for irrigation. While solar water pumping is the logical solution, experience shows that standard solar modules often fail prematurely in the region’s harsh environmental conditions.

This rapid degradation stems from several factors:

- High Ambient Temperatures: Sustained heat can accelerate the aging of module materials, leading to a faster decline in power output.

- Abrasive Dust and Sand: Windblown particles can cause micro-scratches on the module surface, reducing light absorption and overall efficiency.

- High Humidity: In coastal and river regions, humidity can penetrate the layers of a conventional module, causing corrosion and delamination that lead to electrical failure.

These challenges result in failed projects, financial losses, and diminished trust in solar technology precisely where it is needed most. For an agricultural enterprise, an unreliable power source for irrigation is not an inconvenience; it is a direct threat to crop yields and profitability.

The Opportunity: Local Production for a Resilient Agricultural Future

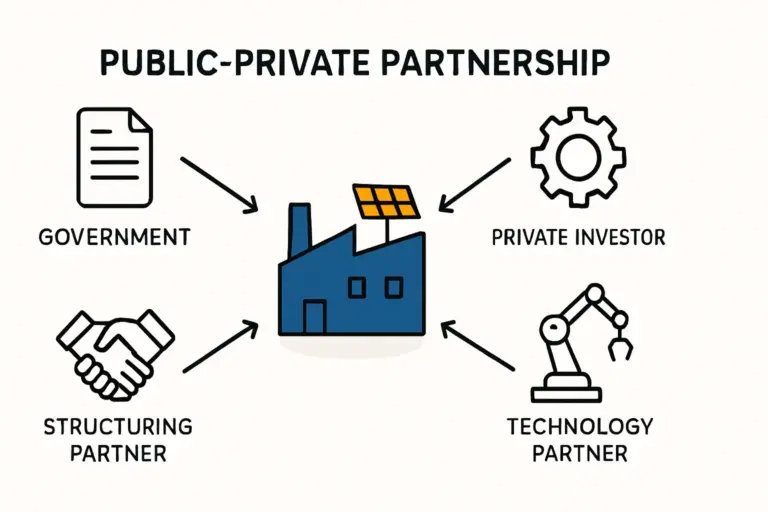

A local manufacturing facility offers a strategic response to these challenges. A domestic enterprise producing its own modules can support Senegal’s national development goals, reduce reliance on imports, and create skilled employment opportunities.

At its core, this opportunity is about engineering a product for its specific environment. Rather than using generic modules designed for milder climates, a local factory can focus on robust technologies built to withstand intense heat, dust, and humidity. This is where specialized engineering, like the DESERT+ technology developed by an established European industrial solutions provider, offers a critical competitive advantage.

Engineering for Longevity: The DESERT+ Glass-Glass Module

To ensure reliability over a 30-year lifespan in demanding climates, a module’s construction must be fundamentally stronger. The key is replacing the standard polymer backsheet with a second layer of glass—a design that provides far superior protection.

Key features of a module designed for arid and tropical conditions include:

- Glass-Glass Structure: Two layers of tempered glass encase the solar cells, creating an impermeable barrier against moisture and mechanical stress.

- Specialized Encapsulants (POE): Using advanced materials like Polyolefin Elastomer (POE) instead of standard EVA prevents moisture ingress and degradation from high temperatures.

- Robust Sealing and Junction Boxes: Edge sealing and electrical connections are designed to prevent dust and water from entering the module, ensuring long-term electrical safety and performance.

By manufacturing modules with these specifications, a Senegalese factory can supply the agricultural sector with a product that delivers predictable power for decades, directly enhancing food security and rural prosperity.

The Execution Framework: A Turnkey Path to Production

For entrepreneurs without a background in solar technology, the prospect of building a factory can seem daunting. However, a structured, turnkey approach demystifies the process by offering a clear roadmap from concept to operation.

Setting up a solar module factory is a phased project, managed to meet all technical, logistical, and operational requirements. Based on experience gained from European PV manufacturers’ turnkey projects, the journey can be broken down into clear, manageable stages.

A comprehensive approach includes:

-

Feasibility and Business Planning: The initial phase involves market analysis, financial modeling, and the development of a detailed business plan tailored to the Senegalese market.

-

Factory Design and Engineering: This stage covers the layout of the production floor, utility planning (power, water, compressed air), and ensuring the facility meets international standards.

-

Equipment Selection and Procurement: Guidance is provided on selecting solar module manufacturing equipment to create a balanced production line that meets quality and throughput targets. The entire solar module manufacturing process is mapped out, from material intake to final product testing.

-

Installation and Commissioning: Expert teams oversee the installation of all machinery and conduct rigorous testing to ensure every component functions correctly.

-

Operator Training and Production Ramp-Up: Local staff are trained on machine operation, quality control protocols, and maintenance procedures, ensuring a smooth transition to full-scale production.

-

Certification Support: Assistance is provided in navigating the process to obtain necessary international certifications (e.g., IEC), which are crucial for market credibility and project bankability.

This methodical process removes the technical barriers to entry, allowing business leaders to focus on strategy and growth while relying on proven expertise for the operational setup.

Frequently Asked Questions (FAQ)

What is the typical investment required for a 20-50 MW factory?

Investment levels vary based on the degree of automation and building specifications. A semi-automated line in this capacity range typically requires an investment in machinery and services starting from €3-5 million. A complete business plan will provide more precise figures.

How many employees are needed to run such a facility?

A semi-automated 20-50 MW production line generally requires 25 to 40 employees, including operators, technicians, quality control personnel, and administrative staff.

How long does the entire setup process take?

With a well-defined plan, a factory can be fully operational in under 12 months from the start of the project.

Is a deep technical background in photovoltaics necessary to start this business?

No. The turnkey model is specifically designed for entrepreneurs and investors who are not solar experts. The partner provides the technical knowledge, engineering, and project management, allowing the owner to lead from a business perspective.

What are the main steps inside the factory?

The core process involves several key stages. It begins with stringing, where individual solar cells are soldered together. These strings are then arranged, laminated between layers of glass and encapsulant, framed, and finally tested before being packaged for shipment.

Next Steps on Your Journey

The intersection of Senegal’s national energy goals and the critical needs of its agricultural sector creates a unique and timely business opportunity. Establishing a local solar module factory is more than an industrial project; it is an investment in food security, energy independence, and sustainable economic development.

A structured, turnkey approach, combined with a focus on advanced module technology designed for the local climate, allows entrepreneurs to enter this high-impact market with confidence. The path is clear, and with the right guidance, the journey from vision to a fully operational factory is well within reach.

Download the Solar for Agribusiness Investment Case Study [PDF]

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.