An investor considering a solar module factory in the Seychelles might initially focus on logistics, technology, and financing. Soon, however, a more critical question emerges: in a nation renowned for tourism and fisheries, where does one find the skilled technical labor to operate a modern manufacturing facility?

This isn’t an insurmountable obstacle but a strategic challenge—one that, addressed correctly, becomes a significant competitive advantage.

A pre-existing pool of photovoltaic manufacturing experts is unlikely to be found locally. The success of such a venture depends not on finding experienced staff, but on creating them. This guide outlines a practical framework for assessing the local labor market, recruiting effectively, and implementing robust training programs to build a world-class Seychellois workforce from the ground up.

Understanding the Seychelles Labor Landscape

The unique economic and demographic profile of the Seychelles presents both challenges and opportunities for a new industrial enterprise. Acknowledging these realities is the first step in developing a realistic human resources strategy.

With a population of just over 100,000, the Seychelles consistently maintains a high employment rate. The dominant industries—tourism, hospitality, and fisheries—absorb a significant portion of the workforce. This creates a competitive labor market where a new manufacturing venture must offer compelling reasons for talent to join.

However, the educational foundation is strong. The country has a high literacy rate, and its primary and secondary education systems are well-regarded. While local institutions like the University of Seychelles and the Seychelles Institute of Technology (SIT) provide valuable vocational skills, many students pursue specialized technical or engineering degrees abroad. This creates a small but valuable pool of internationally educated talent that may be seeking opportunities to return home.

The key challenge is not a lack of capable individuals, but a mismatch between existing skills and the specific needs of industrial manufacturing. The strategic objective is to bridge this gap through a structured development program.

A Three-Pillar Strategy for Workforce Development

A successful approach to building a competent local team for a solar factory rests on three integrated pillars: strategic local recruitment, intensive international training, and a focus on long-term skill retention.

Pillar 1: Local Recruitment and Talent Identification

With a limited labor pool, the focus of recruitment must shift from experience to potential. Instead of searching for candidates with a background in solar manufacturing, the goal is to identify individuals with strong foundational attributes:

-

Technical Aptitude: Candidates from vocational institutions like SIT, particularly those with backgrounds in mechanics, electronics, or general engineering, are excellent prospects.

-

Problem-Solving Skills: The ability to think critically and follow complex processes is more valuable than prior knowledge of specific machinery.

-

Work Ethic and Trainability: A commitment to learning and professional growth is the most important quality for new hires.

Recruitment efforts should target recent graduates and individuals in technical roles in other industries who are seeking a career change. Offering competitive compensation and a clear path for advancement is crucial to attract the best available talent.

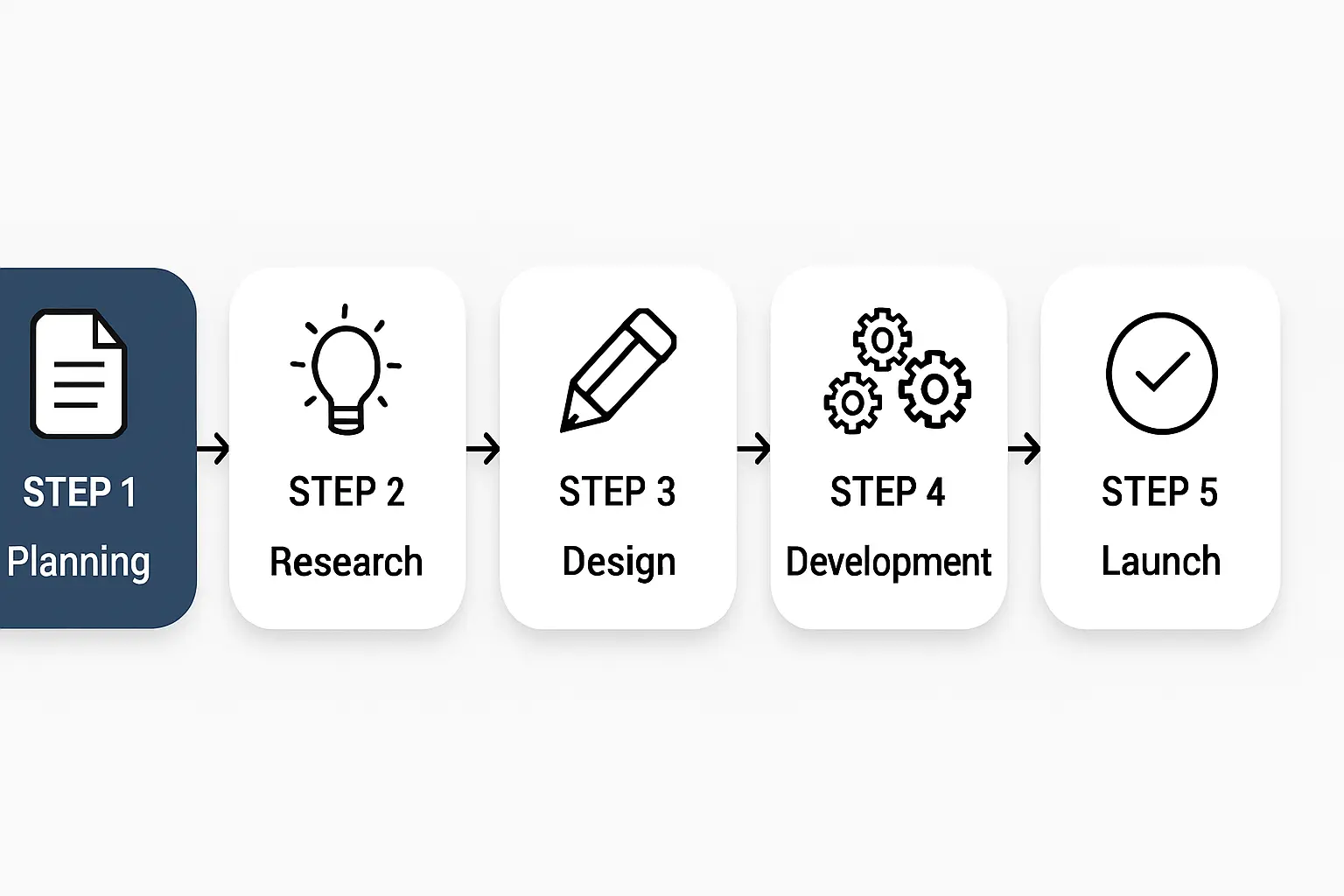

Pillar 2: International Training and Knowledge Transfer

Once a core team is recruited, an intensive knowledge transfer program is essential. Since local expertise in operating solar panel manufacturing machines is unavailable, that expertise must be brought in. This is typically achieved through a ‘Train the Trainer’ model, a method successfully employed in numerous J.v.G. turnkey projects.

This model involves two key phases:

-

Immersive Off-Site Training: A select group of two to four key local personnel (future supervisors and lead technicians) are sent abroad, often to a technology partner’s facility in Germany or another established manufacturing hub. Here, they receive several weeks of intensive, hands-on training on the exact equipment that will be installed in their factory.

-

On-Site Commissioning and Training: When the production line is being installed in the Seychelles, the same international experts who provided the initial training travel to the site. They oversee the final commissioning and, working alongside the newly trained local supervisors, train the rest of the operational staff.

This hybrid approach ensures the core team gains a deep, fundamental understanding of the technology while the entire workforce learns in their actual working environment.

Pillar 3: Long-Term Skill Development and Retention

The initial training is only the beginning. Sustained success requires a culture of continuous improvement and professional development. This involves:

-

Establishing Standard Operating Procedures (SOPs): Clear, documented processes for every task reduce errors and ensure consistency.

-

Ongoing Quality Control Training: Regular training reinforces the high standards required for product certification and market acceptance. This is directly tied to understanding the nuances of solar panel certifications, which is critical for export markets.

-

Creating Career Pathways: Operators should see a clear path to becoming team leaders, maintenance specialists, or quality control supervisors. Such a path offers a powerful incentive for long-term commitment.

By investing in its people, a company not only ensures operational excellence but also builds a loyal, stable workforce, reducing turnover and minimizing the long-term reliance on foreign expertise.

Navigating Regulatory and Administrative Frameworks

The Government of the Seychelles supports economic diversification and has established clear processes for businesses. Any plan involving foreign experts must account for the Gainful Occupation Permit (GOP) system, which regulates the employment of non-Seychellois nationals.

Engaging with the National Human Resource Development Council (NHRDC) early in the planning process is highly beneficial. A clear and committed strategy for training and developing local talent is often viewed favorably and can facilitate smoother administrative processes for the limited number of international trainers required during the startup phase.

Business-Relevant Metrics: Staffing a 20 MW Production Line

To make this tangible, consider the typical staffing requirements for a semi-automated 20–50 MW solar module production line. Such a facility generally requires 25 to 35 employees per shift, broken down as follows:

-

Management & Supervision: 1-2 Plant Managers/Supervisors

-

Engineering & Maintenance: 2-3 Technicians (mechanical and electrical)

-

Production Operators: 15-20 Staff for various stations (stringer, laminator, framer, etc.)

-

Quality Control: 3-5 Inspectors

-

Logistics & Warehouse: 2-4 Staff

The majority of these roles are operational. These operator positions are ideal for local hires who can be trained on specific tasks within a structured, supervised environment. The entire process of planning such an operation is a core part of developing a complete business plan for starting a solar factory.

Frequently Asked Questions (FAQ)

Do we need to hire experienced solar technicians from the start?

No. For a new factory in a market like the Seychelles, it’s more effective to hire for aptitude and attitude. A robust, structured training program is designed to build the necessary skills in a motivated but inexperienced workforce.

How long does it take to train a new workforce?

The initial intensive training for the core team sent abroad typically lasts two to three weeks. On-site training for the full team takes another two to four weeks during machine commissioning. Most operators can become proficient at their specific tasks within this timeframe, with ongoing development continuing over the first year of operation.

Is it better to send staff abroad or bring trainers to the Seychelles?

The most effective strategy is a hybrid model. Sending a small core team abroad for deep immersion builds local leadership and ownership. Bringing trainers on-site to teach the wider team ensures everyone learns on the actual equipment they will be using—a critical step for operational readiness.

What is the biggest labor-related challenge for a new factory in the Seychelles?

The primary challenge is the limited size of the industrial labor pool, which makes employee retention critical. A company must be seen not just as an employer but as an institution for career development, offering competitive wages, benefits, and clear opportunities for advancement to retain the talent it has so carefully trained.

Your Path to a Competent Local Team

Building a solar module factory in the Seychelles is an ambitious and promising venture. While the challenge of sourcing skilled labor is real, it’s entirely manageable with foresight and a well-executed strategy. By focusing on identifying local potential, investing in world-class training, and fostering a culture of long-term development, an investor can create a highly skilled and motivated Seychellois workforce.

This investment in human capital is the ultimate foundation for sustainable manufacturing success.