For many entrepreneurs considering starting a solar business, the primary focus is on machinery, financing, and facility planning. However, a critical question often arises later in the process: Who will operate the sophisticated equipment required for solar panel assembly?

In a market like Sierra Leone, with a limited industrial manufacturing base, this can seem like a significant barrier. The reality, however, is a compelling opportunity. With youth unemployment rates as high as 60% according to the World Bank, Sierra Leone has a vast and motivated potential workforce. The challenge isn’t a lack of people, but the absence of a structured system to transform this potential into a high-performing technical team. This guide outlines a practical framework for sourcing, training, and retaining the skilled labour essential for a successful solar panel factory.

Understanding the Sierra Leonean Labour Landscape

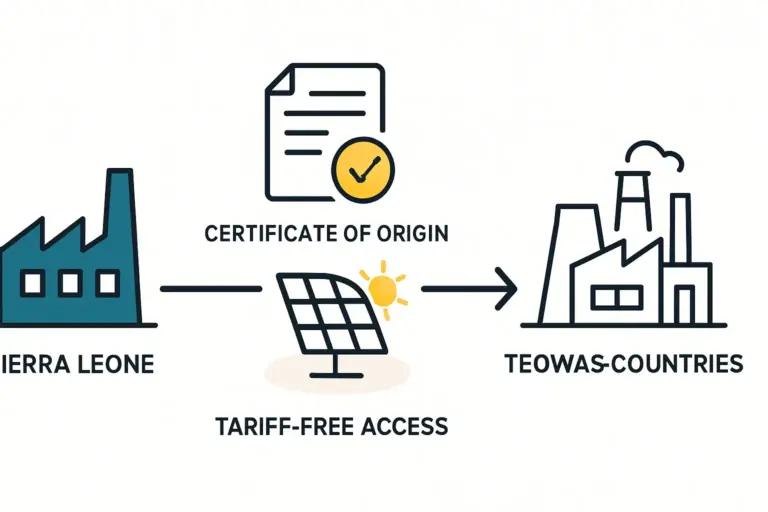

An investor’s strategy must be rooted in the local economic context. Sierra Leone’s economy, traditionally reliant on agriculture and mining, is actively seeking diversification. This national ambition aligns perfectly with establishing local manufacturing, positioning a new solar enterprise to contribute directly to economic development.

Key characteristics of the labour market include:

- A Large Youth Demographic: A significant portion of the population is under 30, representing a long-term human resource asset.

- Limited Industrial Precedent: Few candidates will have prior experience in a formal, high-precision manufacturing environment, meaning resumes may not be the most effective screening tool.

- Growing Vocational Training: The government and international partners, as noted by the African Development Bank (AfDB), are investing in Technical and Vocational Education and Training (TVET). However, a gap often exists between academic curricula and specific industry needs.

Success, therefore, depends not on finding pre-existing skills, but on establishing an effective system for building them from the ground up.

A Phased Approach to Recruitment and Sourcing

A conventional recruitment process may fail to identify the best candidates. Instead, focusing on aptitude and potential is a far better predictor of success in a technical assembly role.

Phase 1: Identifying Foundational Attributes

Instead of searching for ‘solar technicians,’ the initial search should target core attributes that are transferable to the manufacturing floor. These include:

- Manual Dexterity: The ability to handle small components with care.

- Attention to Detail: Critical for quality control and process adherence.

- Problem-Solving Aptitude: The capacity to understand cause and effect in a mechanical process.

- Consistency and Discipline: The temperament to perform repetitive tasks to a high standard.

Phase 2: Structuring the Recruitment Process

An effective process prioritizes practical evaluation over interviews. Consider aptitude tests that simulate factory tasks, such as assembling a simple mechanical toy or following a complex visual diagram. This allows candidates to demonstrate their potential directly, providing a much clearer indicator of their suitability than a formal interview. Sourcing candidates from local TVET institutions can provide a pool of individuals who have already shown an interest in technical work.

Phase 3: Partnering with Local Institutions

Engaging with local technical colleges and community leaders builds goodwill and creates a sustainable pipeline of talent. By providing input on curriculum or offering internships, a new factory can become an integral part of the local economic fabric and ensure a long-term supply of suitable candidates.

Designing an Effective Technical Training Programme

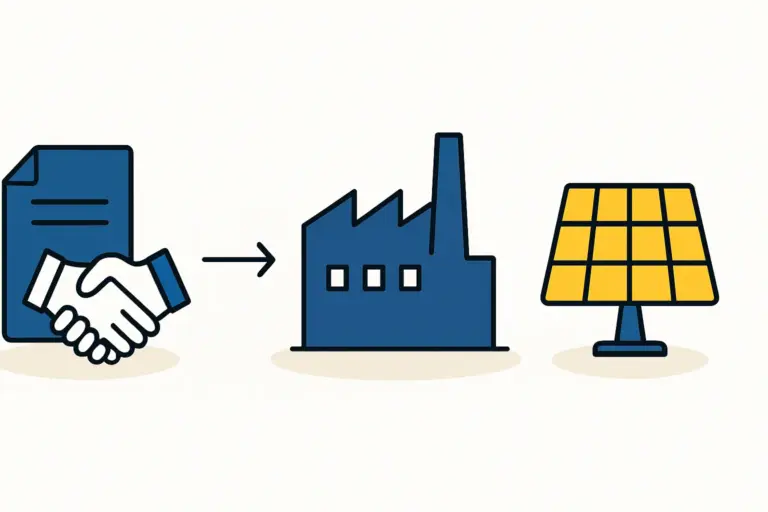

Once a team is recruited, a structured, hands-on training programme is the most critical investment. Based on experience from J.v.G. turnkey projects, a ‘train the trainer’ model is highly effective. This approach typically involves an experienced expatriate technician who leads the initial training and develops a local training supervisor.

From Theory to Practice: A Modular Approach

The training should be broken down into modules that directly correspond to the stations on the production line. A comprehensive understanding of the full solar panel manufacturing process is essential for context, but mastery is built one step at a time.

A typical training flow would cover:

- Workplace Safety & Professional Conduct: Establishing a strong culture from day one.

- Materials Handling: Understanding the properties and correct handling of glass, EVA, solar cells, and backsheets.

- Cell Stringing & Bussing: The most delicate manual step, requiring precision and soldering skill.

- Layup & Inspection: Assembling the ‘sandwich’ of materials before lamination.

- Laminator Operation: Managing the automated process of heating and pressing the module.

- Framing & Junction Box Installation: The final assembly steps.

- Quality Control & IV Testing: Using the sun simulator (flasher) to test and classify the finished panel.

This modular approach ensures that employees become proficient at a specific station before moving on, building confidence and maintaining quality control throughout the line. For investors, turnkey solar factory solutions often include pre-designed training manuals and process documentation, significantly shortening the time required to bring a new team to full productivity.

Insight from the Field: A Nigerian Case Study

In a similar project in Nigeria, the initial workforce consisted of individuals with backgrounds in mobile phone repair and tailoring. While they had no solar experience, their existing skills in soldering and handling delicate materials made them ideal candidates. A six-week intensive training program, led by an external expert, was sufficient to bring the first production line to its target output and quality standards. This case underscores the importance of focusing on transferable skills rather than specific industry experience.

Retention Strategies: From a Job to a Career

High staff turnover can cripple a new manufacturing operation, making a retention strategy just as important as the initial training. The goal is to position the factory as a premier local employer where individuals can build a long-term career.

Creating Pathways for Advancement

Clearly defined career paths provide powerful motivation. A line worker can aspire to become a Senior Technician, a Quality Control Inspector, or a Line Supervisor. This internal promotion structure rewards high performers and builds a deep base of institutional knowledge.

The Importance of a Professional Work Environment

Maintaining high standards for safety, cleanliness, and professional conduct is essential. Competitive wages, clear communication from management, and fair treatment demonstrate that the company values its employees, fostering loyalty and dedication. In regions where formal manufacturing jobs are scarce, becoming an employer of choice is a distinct competitive advantage.

By investing in people with the same seriousness as they invest in machinery, an entrepreneur in Sierra Leone can not only build a profitable business but also become a catalyst for local industrial development, harnessing the nation’s greatest resource: its people.

Frequently Asked Questions (FAQ)

-

What technical background is truly necessary for entry-level assembly line workers?

For most roles on an assembly line, no prior technical degree is required. The most important qualifications are strong manual dexterity, the ability to follow precise instructions, and a commitment to quality. Aptitude and attitude are more critical than formal qualifications. -

How long does it take to train a new team to operate a solar production line?

A well-structured, intensive training program can typically bring a new team to proficiency within four to six weeks. Reaching optimal speed and efficiency may take an additional two to three months of on-the-job experience. -

Is it better to hire a few experienced technicians from abroad?

It’s highly recommended to have one or two experienced lead technicians (often expatriates) to manage the initial setup and training phase. However, the long-term goal should be to develop a fully local team, including supervisors and quality managers. This approach is more cost-effective and sustainable. -

How does a solar factory contribute to the local economy beyond direct employment?

A local solar panel factory creates a ripple effect. It can stimulate local supply chains for items like packaging materials and aluminum frames, create jobs in logistics and transportation, and provide a reliable source of solar panels for local installation companies, fostering a broader renewable energy ecosystem as envisioned by organizations like IRENA. -

What are the first steps in developing a workforce plan for a new factory?

The first step is to map out every role required on the production floor, from materials intake to final packaging. For each role, define the core skills and aptitudes needed. This map becomes the foundation for your recruitment, testing, and training strategy.