Labor Force Strategy for a Singapore Solar Factory: Balancing Automation and Skilled Manpower

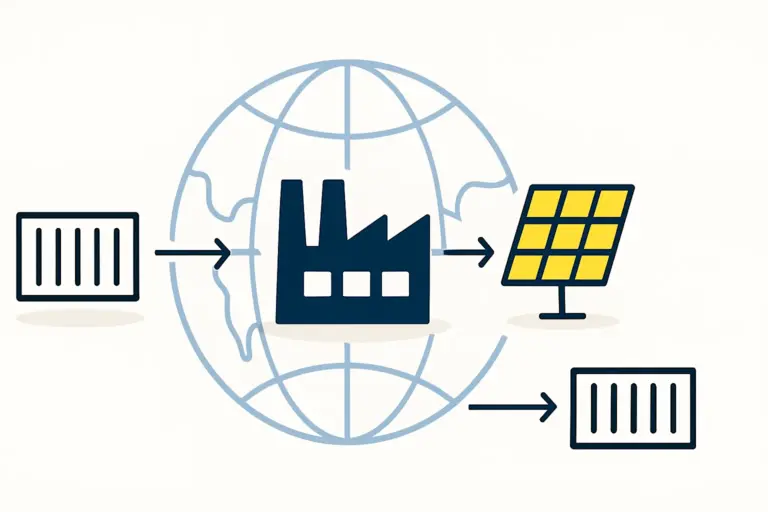

An entrepreneur considering a solar module factory in Singapore faces a unique paradox. While the nation is a global hub for high-tech manufacturing with exceptional infrastructure and political stability, the high cost of labor and land poses a significant challenge, seemingly at odds with the traditional manufacturing model.

This raises a critical strategic question: Is the path to profitability through heavy automation, a highly skilled local workforce, or a sophisticated blend of both?

This analysis explores the strategic considerations for establishing a solar module production workforce in Singapore. It examines how to leverage the nation’s strengths in technology and human capital to build a competitive and sustainable manufacturing operation, turning perceived economic hurdles into strategic advantages.

The Unique Manufacturing Landscape of Singapore

A sound labor strategy begins with understanding the specific economic and policy environment in Singapore. Unlike manufacturing hubs in other parts of Asia, Singapore’s model is not built on low-cost labor. Instead, several factors define its model and heavily influence operational decisions.

Key Environmental Factors:

-

High Labor Costs: Competitive salaries and benefits for local talent are standard, making labor a primary operational expense.

-

Foreign Worker Quotas and Levies: The government regulates the number of foreign workers a company can hire and imposes levies, creating a direct financial incentive to maintain a lean, highly productive workforce.

-

Government Push for Industry 4.0: Through its ‘Smart Nation’ initiative, Singapore actively promotes the adoption of advanced manufacturing technologies. Government bodies, such as the Economic Development Board (EDB), offer significant incentives and grants, like the Enterprise Development Grant (EDG), to support companies investing in automation and digitalization.

-

Emphasis on Skills Development: Recognizing the need for a workforce capable of managing automated systems, the government has invested heavily in upskilling and reskilling programs, most notably through the SkillsFuture Singapore (SSG) agency.

This environment systematically discourages labor-intensive, low-margin manufacturing. It rewards businesses that invest in technology to enhance productivity and create higher-value roles for a skilled workforce. For a solar factory, this means the traditional calculation of labor versus capital investment is fundamentally different.

The Case for Advanced Automation in Solar Manufacturing

In Singapore’s context, automation is less a luxury than a foundational component of a viable business model. The return on investment (ROI) isn’t calculated against direct labor savings alone, but also against the costs of levies, recruitment challenges, and dependence on foreign workers.

Advanced automation addresses Singapore’s core challenges directly. Robotic systems for cell stringing, automated bussing, and integrated conveyor systems operate 24/7 with a consistency unmatched by human operators, leading to several key benefits:

-

Increased Throughput: Automated lines can produce modules at a faster, more predictable rate.

-

Improved Quality and Yield: Precision robotics minimize handling errors and material wastage, critical when handling delicate silicon cells in the solar panel manufacturing process.

-

Reduced Operational Footprint: An efficient, automated layout can maximize output in a smaller physical space, a crucial advantage given Singapore’s high land costs.

The initial cost of a solar panel production line is higher for an automated setup. However, when factoring in the long-term operational savings from reduced labor requirements and government grants designed to offset capital expenditure, the financial case becomes compelling. Based on experience from J.v.G. turnkey projects, an investor can achieve a more predictable and scalable operation by prioritizing automation from the outset.

The Indispensable Role of a Skilled Workforce

A common misconception is that automation aims to eliminate the human workforce. In reality, it redefines its role. An automated factory isn’t a ‘no-person’ factory; it’s a ‘new-person’ factory that relies on a smaller, more highly skilled team.

While robots perform repetitive physical tasks, skilled technicians and engineers are essential for functions that require critical thinking, problem-solving, and expertise.

Key Roles for Human Talent in an Automated Factory:

-

Process Engineers: Responsible for optimizing the production line, programming robotic systems, and improving overall efficiency.

-

Maintenance Technicians: Crucial for ensuring high uptime of complex machinery through preventative maintenance and rapid troubleshooting.

-

Quality Assurance Specialists: While automated optical inspection (AOI) is standard, human oversight is vital for a robust solar panel quality control system. Specialists interpret data, manage edge cases, and ensure final product certification standards are met.

-

Data Analysts: Modern factories generate vast amounts of data. Analysts interpret this data to predict maintenance needs, identify production bottlenecks, and drive continuous improvement.

Singapore’s highly educated population is a significant asset in filling these roles. The challenge is often not a lack of general technical aptitude but a specific skills gap in solar manufacturing. This requires a commitment to robust in-house training programs, often developed in partnership with local polytechnics and educational institutions.

Finding the Optimal Balance: A Strategic Framework

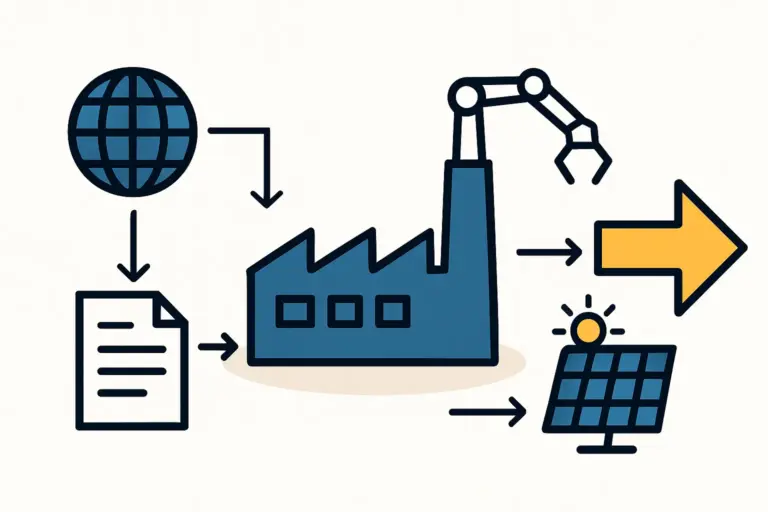

The most effective strategy isn’t a binary choice between machines and people, but rather a phased integration that aligns with business growth. This approach allows for a manageable initial investment while building human capabilities in parallel.

A logical progression for a new entrant could be structured as follows:

-

Phase 1: Core Process Automation: Begin by automating the most critical and repetitive stages, such as cell stringing and lamination. Manual or semi-automated processes can be used for less critical steps like framing and junction box attachment, where skilled operators can add value through careful inspection.

-

Phase 2: Integrated Line Automation: As production scales, invest in connecting automated stations with integrated material handling systems. This reduces manual intervention between steps and increases overall line speed and predictability.

-

Phase 3: Smart Factory Implementation: The final phase involves layering on digital technologies—sensors, data analytics, and machine learning—to create a fully ‘smart’ factory. This enables predictive maintenance, real-time performance monitoring, and data-driven decision-making.

Engaging with an experienced partner for a turnkey solar factory solution can be a significant advantage. Such partners can help design a phased implementation plan tailored to an investor’s budget and long-term goals, ensuring that the technology and workforce strategies evolve together.

Frequently Asked Questions (FAQ)

What is the typical staff size for a semi-automated 50 MW line in Singapore?

A semi-automated 50 MW line in Singapore typically requires 25 to 40 personnel per shift. This number includes not only line operators but also a higher proportion of skilled maintenance technicians, process engineers, and quality control staff compared to a manual factory in a lower-cost region.

How do foreign worker levies impact the decision to automate?

Foreign worker levies are a significant, recurring operational cost. For every work permit holder employed, a monthly levy must be paid to the government. Automation directly reduces the number of operators required, which in turn lowers total levy payments and decreases reliance on a regulated labor pool. This makes the financial return on automation much faster in Singapore than in countries without such a levy system.

Is it difficult to find trained solar technicians in Singapore?

While the pool of experienced solar manufacturing technicians may be limited, Singapore has a strong base of talent in adjacent high-tech fields like semiconductors and electronics manufacturing. These professionals possess transferable skills in automation, cleanroom protocols, and quality control. The key is a structured internal training program to bridge the specific knowledge gap in photovoltaic technology, often supplemented by government-supported skills development courses.

Can a factory be fully automated without any human workers?

The concept of a ‘lights-out,’ fully autonomous factory remains largely theoretical for complex manufacturing like solar module production. While automation can handle the vast majority of physical assembly tasks, human expertise remains indispensable for setup, calibration, complex maintenance, process optimization, and strategic decision-making. The goal of automation is to empower the human workforce, not replace it.

Conclusion

Establishing a successful solar module factory in Singapore requires a strategy that embraces its unique economic realities. By pairing advanced automation with a well-trained, highly skilled technical workforce, an investor can transform the nation’s high costs from a liability into a competitive advantage, creating a world-class manufacturing operation built for quality, efficiency, and long-term resilience. For entrepreneurs exploring this path, the next step is detailed financial modeling and process mapping to define the optimal balance for their specific business case.