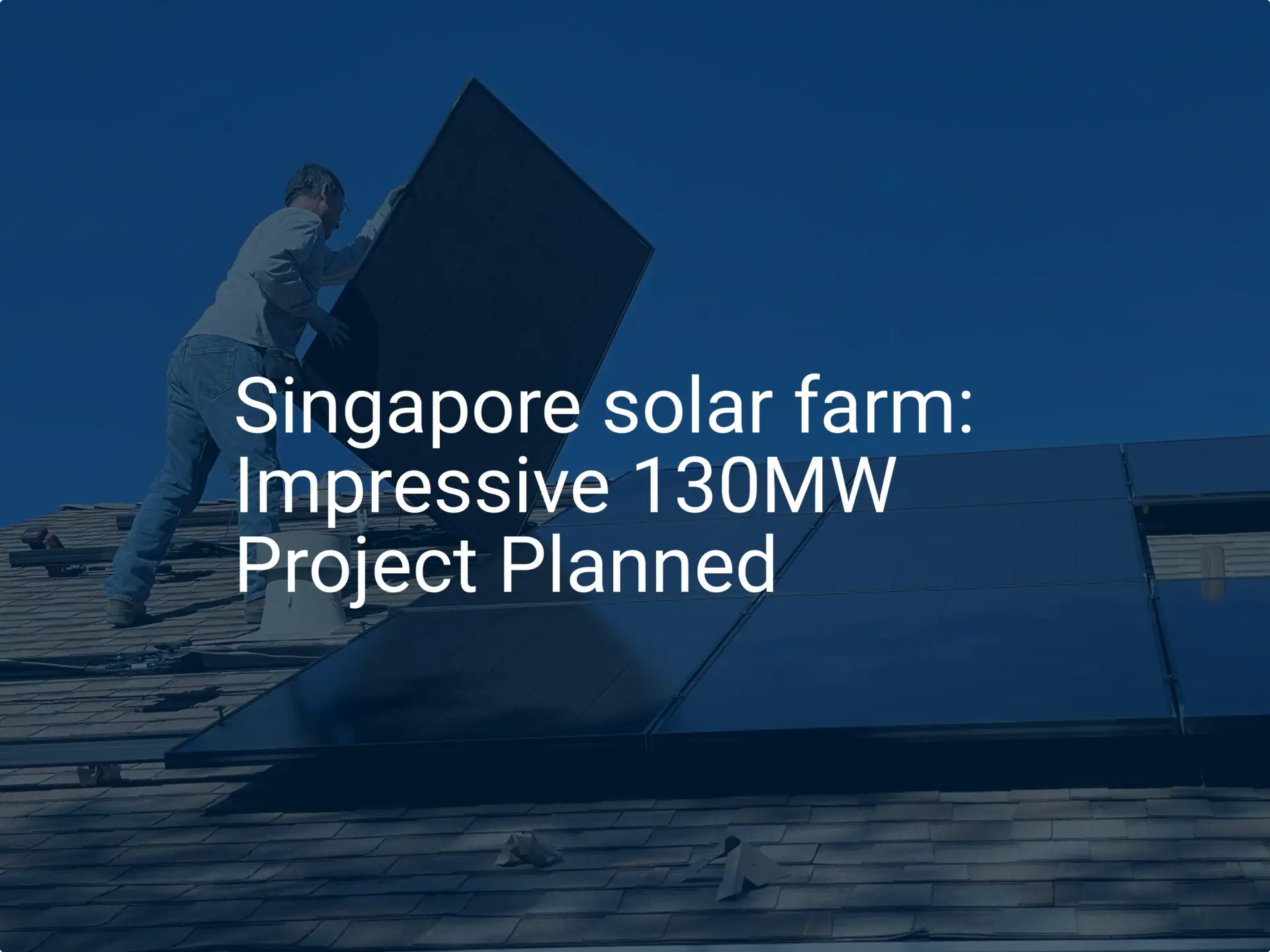

Many entrepreneurs view Singapore as a prime location for high-tech manufacturing, drawn by its political stability, skilled workforce, and logistical advantages. This pro-business environment, however, rests on a foundation of strict, non-negotiable regulatory standards.

For those looking to enter the solar module manufacturing industry, understanding the requirements of the National Environment Agency (NEA) isn’t just a procedural step—it’s a critical factor for project success and long-term operational viability.

An investor might secure funding and identify a promising market, only to face significant delays and unexpected costs because crucial environmental compliance details were addressed too late in the planning process. This guide offers a clear overview of the NEA’s regulatory framework, helping business leaders anticipate requirements, plan effectively, and navigate the path to establishing a compliant and successful solar manufacturing facility in Singapore.

The Regulatory Framework: Understanding the NEA and the EPMA

The National Environment Agency (NEA) is the primary public organization responsible for improving and sustaining a clean and green environment in Singapore. Its authority comes from several key pieces of legislation, the most important for industrial facilities being the Environmental Protection and Management Act (EPMA) and its subsidiary regulations.

The EPMA gives the NEA the legal power to control pollution and regulate activities that could impact public health and the environment. For a solar panel manufacturer, this means every aspect of the proposed operation—from air emissions and water discharge to chemical storage and waste disposal—will be subject to the NEA’s scrutiny.

The core philosophy is preventative. Rather than relying on corrective measures after a problem arises, the NEA requires businesses to design their processes to be inherently clean and sustainable. This proactive approach defines the entire permitting process.

Key Stages in the NEA Permitting Process

Navigating the NEA’s requirements is a structured process. While specifics may vary with an operation’s scale and complexity, the typical journey involves several key milestones. A common pitfall for new industrial projects is failing to sequence these regulatory steps correctly within the overall project timeline.

1. Preliminary Assessment and Site Selection:

Before any significant capital is invested, it’s essential to confirm the proposed site is zoned for industrial use by the Urban Redevelopment Authority (URA). The NEA works in tandem with the URA to ensure a factory’s potential environmental impact is compatible with its location.

2. The Pollution Control Study (PCS):

This is the most critical technical submission. The PCS is a comprehensive report detailing all potential sources of pollution from the factory and the measures that will be implemented to control them. It must be prepared by a competent person, typically an environmental engineering consultant.

The study covers:

-

Air Pollution: Analysis of emissions from processes like soldering, lamination, and the use of solvents, including specifications for exhaust systems and scrubbers.

-

Water Pollution: Details on wastewater treatment facilities to manage effluents from processes such as cell washing and equipment cleaning.

-

Hazardous Substances: A complete plan for the storage, handling, and use of chemicals like silane, acids, and industrial solvents.

-

Waste Management: Procedures for segregating, storing, and disposing of solid and chemical waste, including broken cells, EVA trim, and used chemicals.

-

Noise Pollution: Measures to control noise from machinery like compressors and ventilation systems to ensure it remains within permissible limits.

The PCS must demonstrate, with clear engineering data, that the facility will comply with all relevant standards outlined in the EPMA regulations.

3. Application for Written Permission:

Once the PCS is complete, it is submitted to the NEA as part of an application for Written Permission. This document is effectively the NEA’s go-ahead for the construction and installation of the plant and its pollution control systems. No construction can legally begin without this permission.

4. Securing Operational Licenses:

After the facility is constructed and the pollution control equipment is installed, the NEA will conduct an inspection. If the facility is built as described in the approved PCS, the NEA will issue the necessary operational licenses. These may include:

-

Written Approval for Use of Hazardous Substances: Required for storing and using specific quantities of regulated chemicals.

-

Toxic Industrial Waste Collector’s License: Necessary for managing the disposal of hazardous waste materials.

This multi-stage process ensures environmental considerations are integrated into a facility’s design from day one.

Meeting Specific Environmental Standards in Solar Manufacturing

While solar energy is clean at the point of generation, its manufacturing involves materials and processes that demand careful environmental management. The NEA has stringent, quantifiable standards that all facilities must meet.

Air Emission Control

Solar module assembly can release Volatile Organic Compounds (VOCs) from solvents and fluxes used in the stringing and bussing stages; the lamination process can also generate fumes. A manufacturing facility must install and operate appropriate air pollution control equipment, such as scrubbers or thermal oxidizers, to ensure emissions do not exceed the limits set in the EPMA (Clean Air) Regulations.

Wastewater Management

Water used for cleaning solar cells and equipment can contain chemical residues and particulate matter. An on-site wastewater treatment plant is typically required to treat this effluent before it is discharged into the public sewer system. The treated water must comply with the permissible limits for pH, chemical oxygen demand (COD), and heavy metals outlined in the EPMA (Trade Effluent) Regulations. This directly impacts factory layout and building requirements, as the layout must allocate space and infrastructure for such a plant.

Solid and Hazardous Waste Disposal

Solar manufacturing generates various waste streams, from non-hazardous materials like packaging and EVA scraps to hazardous waste like broken solar cells (which may contain trace amounts of heavy metals) and spent chemical containers. The NEA requires a strict waste segregation and management plan. Hazardous waste must be handled by a licensed Toxic Industrial Waste Collector, and these operational costs must be factored into the business’s financial projections.

Common Pitfalls for New Investors

Based on experience from J.v.G. Technology GmbH turnkey projects in various regulatory environments, several common challenges emerge when dealing with stringent bodies like the NEA.

Underestimating Timelines:

The PCS process and subsequent approvals can take several months. This timeline must be realistically factored into the overall project schedule. Starting this process late is a frequent cause of costly delays.

Incomplete Documentation:

The NEA requires detailed and precise information. Vague descriptions of pollution control measures or incomplete chemical inventories will lead to an application’s rejection, forcing revisions and restarting the review clock.

Ignoring Ongoing Compliance:

Obtaining the initial permits is only the beginning. The NEA requires regular monitoring, record-keeping, and reporting to ensure the facility remains compliant throughout its operational life. A robust investment plan must account for these ongoing operational expenses, covering both initial and recurring compliance costs.

Frequently Asked Questions (FAQ)

Q1: What is the typical timeframe for obtaining NEA approval for a new factory?

A1: For a medium-sized industrial facility, the process from preparing the Pollution Control Study (PCS) to receiving final operational licenses can take 6 to 12 months. This timeframe depends heavily on the project’s complexity and the quality of the initial submission.

Q2: Is it necessary to hire a local environmental consultant?

A2: While not legally mandatory, it is highly recommended. A local consultant with experience navigating the NEA’s processes can prepare a high-quality PCS, anticipate potential issues, and communicate effectively with the authorities, significantly streamlining the approval process.

Q3: What are the penalties for non-compliance with NEA regulations?

A3: Penalties can be severe, including substantial fines, stop-work orders, and, in serious cases, imprisonment for company officers. The NEA has a strong enforcement track record, making compliance an absolute business necessity.

Q4: Do these regulations also apply to smaller, pilot-scale manufacturing lines?

A4: Yes, the principles of the Environmental Protection and Management Act (EPMA) apply to all industrial activities, regardless of scale. However, the specific requirements and complexity of the submissions may be adjusted based on the facility’s potential environmental impact. A smaller line may have less extensive requirements than a 500 MW factory but will still need to demonstrate compliance.

Next Steps in Your Planning Journey

Successfully navigating Singapore’s environmental regulations requires diligence, expertise, and, most importantly, early planning. By treating compliance as a core project component rather than an administrative hurdle, entrepreneurs can build a solid foundation for a sustainable and profitable solar manufacturing operation.

Understanding the regulatory landscape is a crucial first step. Now, it’s time to integrate these requirements into your comprehensive business plan, detailing the necessary technology and defining the physical infrastructure of your proposed factory.