Imagine a modern glass-clad office building in Bratislava. From the outside, it’s a sleek architectural statement, but its facade is more than just glass—it’s an active power station generating electricity for the occupants inside. This isn’t a futuristic concept; it’s the reality of Building-Integrated Photovoltaics (BIPV), a market where construction materials and solar technology converge.

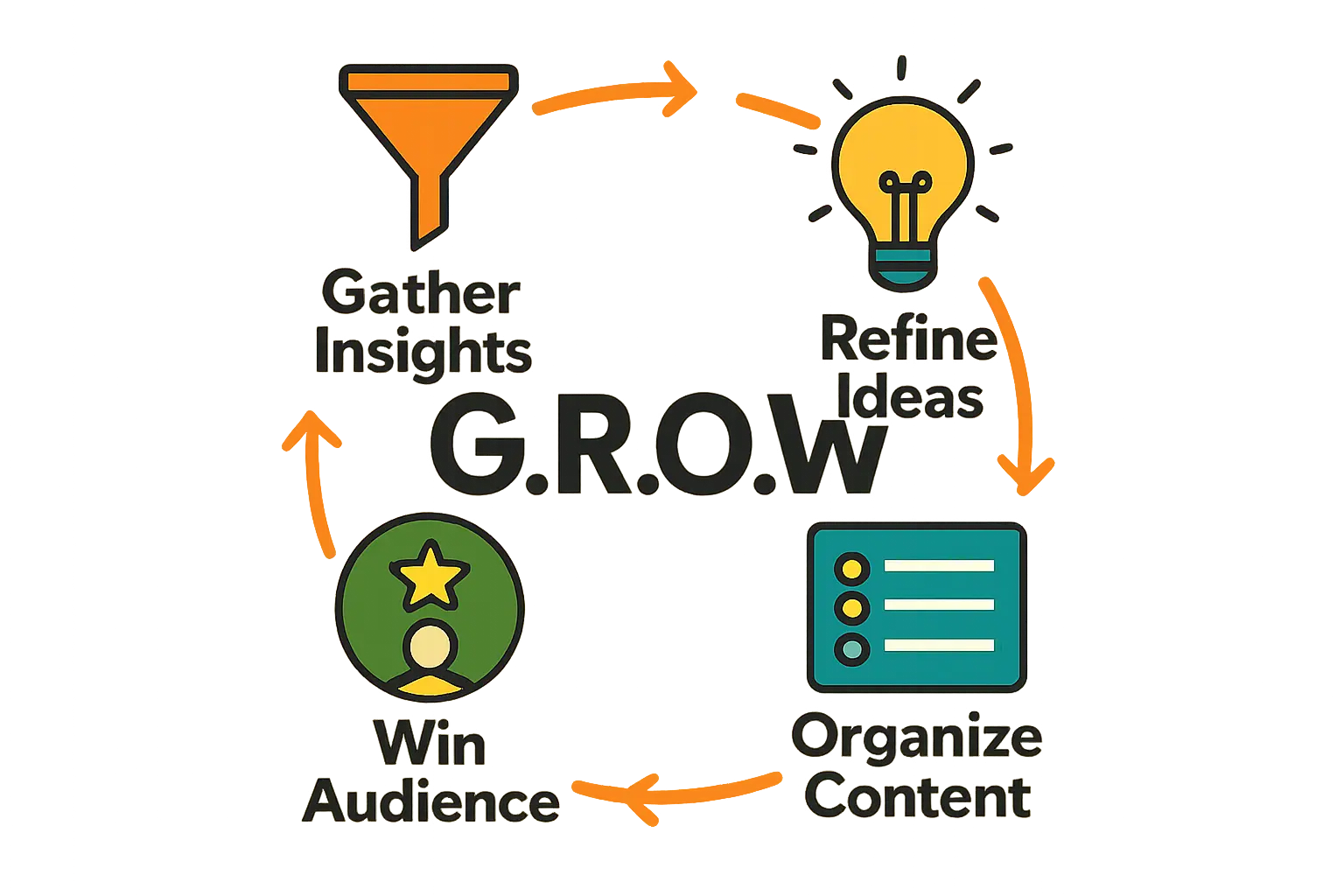

While the market for standard solar panels is well understood, a more sophisticated and profitable niche is expanding rapidly across Europe. This article explores the business case for establishing a specialized BIPV production line in Slovakia, a country uniquely positioned to meet the continent’s growing demand for green building solutions.

Understanding the Shift from Standard Solar to BIPV

To appreciate this opportunity, it helps to distinguish between the two main approaches to solar on buildings. The most common is Building-Applied Photovoltaics (BAPV), where standard solar panels are mounted onto an existing roof or structure as an addition.

Building-Integrated Photovoltaics (BIPV), in contrast, replace conventional building materials entirely. BIPV products are multifunctional, serving as part of the building’s envelope—such as the roof, facade, or windows—while generating electricity.

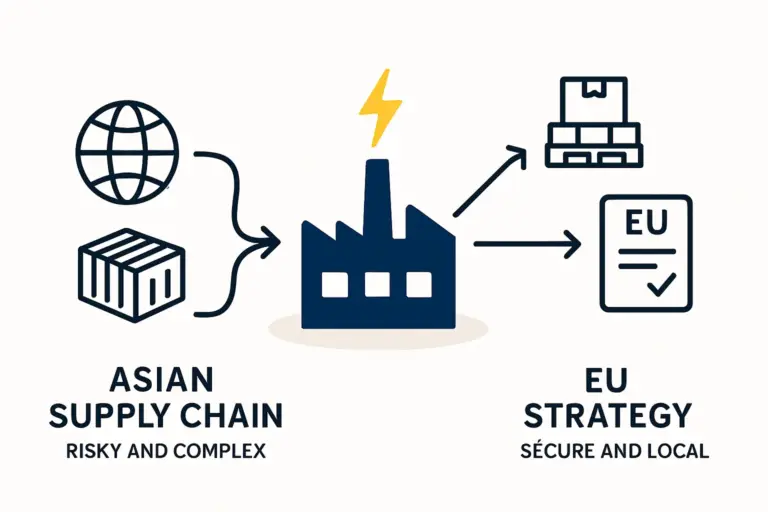

From a business perspective, this distinction is critical. The market for standard solar modules is increasingly commoditized, facing intense price pressure from large-scale international manufacturers. BIPV, however, represents a move up the value chain. It’s a market defined by architectural integration, customization, and higher margins, where close customer collaboration and technical consultation are key competitive advantages.

The Regulatory Tailwinds: Why Europe is Primed for BIPV

A powerful force is accelerating BIPV adoption across the continent: regulation. The European Union’s Energy Performance of Buildings Directive (EPBD) mandates that by 2030, all new buildings must be Zero-Emission Buildings. This legal requirement is fundamentally changing the construction industry.

Architects and developers are no longer simply encouraged to build sustainably; they are required to. This regulatory push transforms BIPV from a niche architectural feature into an essential construction component. The market reflects this urgency, with projections showing global BIPV revenues growing from roughly USD 14.5 billion in 2023 to over USD 59.5 billion by 2030. For an entrepreneur, this creates a clear and predictable demand curve driven by law.

Slovakia’s Strategic Advantage: A Manufacturing Hub in the Heart of Europe

While the demand for BIPV is Europe-wide, the ideal location for its production requires a specific combination of factors. Slovakia presents a compelling case based on its industrial heritage, logistical position, and economic environment.

Industrial Heritage and Skilled Labour

Slovakia has a robust industrial manufacturing base, particularly in the automotive sector. This heritage provides two crucial assets: a workforce skilled in precision engineering and automated production, and an established ecosystem of suppliers for materials like specialized glass, aluminum frames, and electronics. An entrepreneur establishing a BIPV facility here would not be starting from scratch but leveraging this existing industrial capability.

Logistical Excellence

Situated at the heart of Europe, Slovakia offers unparalleled logistical access to key BIPV markets, including Germany, Austria, Poland, and the Czech Republic. BIPV projects are often highly customized, requiring close collaboration between the manufacturer, architect, and construction team on a tight timeline. A centrally located factory can provide just-in-time delivery to building sites across the region—a significant advantage over distant, mass-production competitors. This strategic location can substantially reduce transport costs and lead times, strengthening the business case for a local solar module production line.

Favourable Economic Conditions

Compared to its Western European neighbours, Slovakia offers a more competitive operational cost structure for both labour and facilities. This allows a BIPV manufacturer to produce high-value, European-made products while maintaining a competitive price point—a critical factor for success in the building materials industry.

The BIPV Production Model: High-Value, Not High-Volume

A BIPV manufacturing strategy differs fundamentally from that of a standard solar panel factory. The goal is not to produce millions of identical units, but to offer a portfolio of customizable, high-margin products.

This business model thrives on flexibility. Production might involve creating solar roof tiles that mimic traditional slate, semi-transparent facade elements for curtain walls, or coloured panels that match a specific architectural design. This approach requires a close partnership with the architectural and construction communities, positioning the manufacturer as a solutions provider, not merely a component supplier. Such a specialized focus insulates the business from the price volatility of the commodity solar panel market.

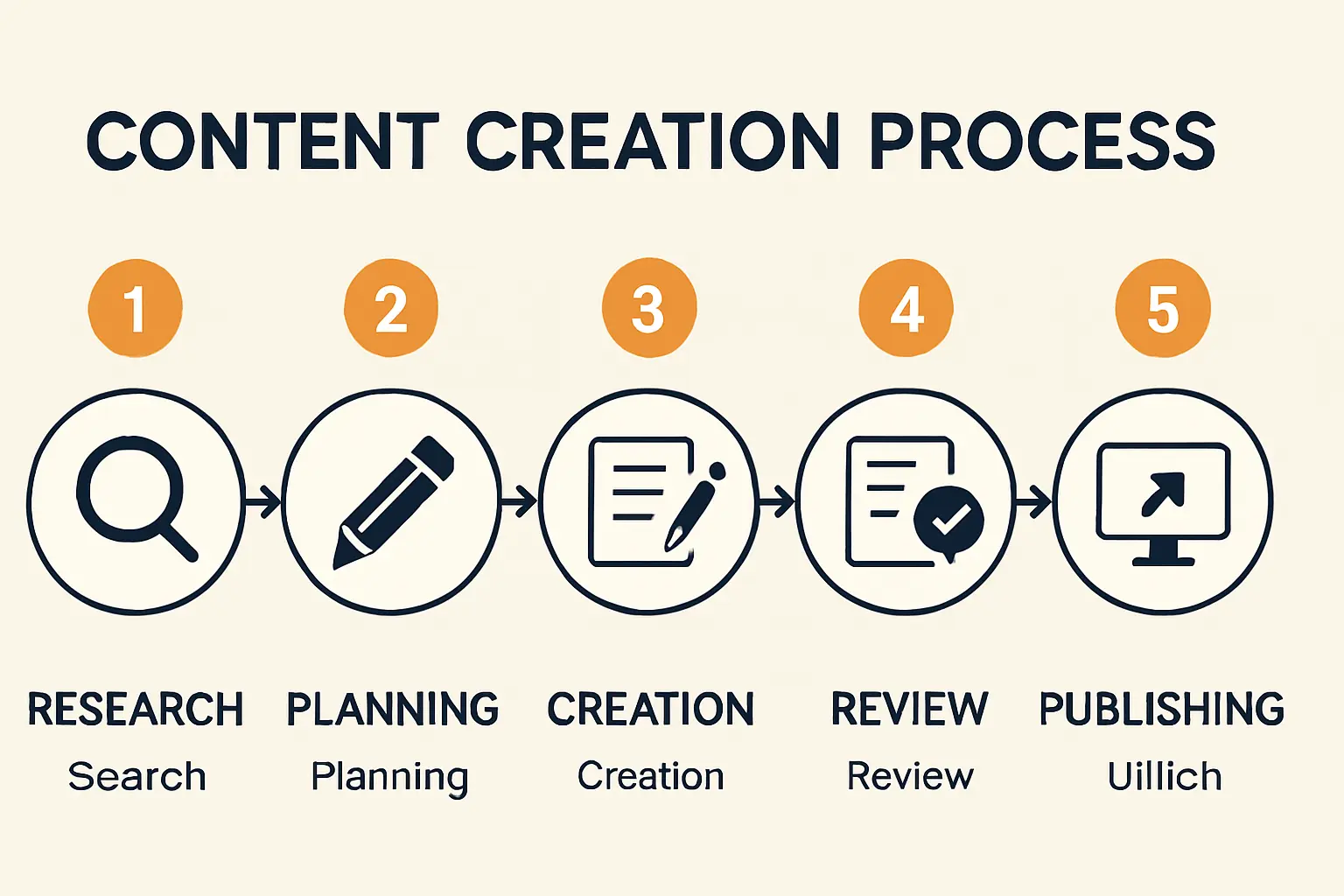

Key Considerations for Establishing a BIPV Factory

Venturing into BIPV production requires careful planning. The machinery needed is often more specialized than for standard modules, as it must handle different materials, sizes, and cell technologies. A comprehensive business plan is essential for understanding the initial investment requirements and operational costs.

Accessing the European market also requires adherence to stringent quality and safety standards, such as TÜV and CE certifications. Understanding the nuances of BIPV technology and its specific certification pathways is paramount. Experience from J.v.G. turnkey projects shows that securing these certifications is a critical milestone that must be integrated into the project plan from day one.

Frequently Asked Questions (FAQ)

What is the primary difference between BIPV and regular solar panels?

The primary difference lies in function and integration. Regular panels (BAPV) are added to a building, whereas BIPV products replace a conventional building material, serving a dual purpose as both a structural element (like a roof tile or facade panel) and a power generator.

Is a BIPV factory significantly more expensive to set up than a standard one?

The initial investment can be comparable, but the equipment is more specialized to allow for greater product variety and customization. The business model, however, focuses on higher margins per unit rather than high-volume output, which changes the overall financial projections.

Who are the primary customers for BIPV products?

The primary customers are architects, construction companies, and real estate developers creating new commercial, public, or high-end residential buildings that must comply with modern energy efficiency standards.

Why is Slovakia a potentially better location than a country like Germany?

Slovakia offers a unique combination of advantages: a skilled industrial workforce and supplier base derived from its automotive industry, a more competitive cost structure for labour and operations, and a strategic central location providing efficient logistical access to major European markets like Germany.

How complex is the technology involved in BIPV manufacturing?

BIPV manufacturing is more complex than standard module production because it requires customization in size, shape, colour, and transparency. However, the core photovoltaic technology is mature. Success depends on well-defined production processes and partnering with experienced technology providers who can guide the setup and operation.

Conclusion: Seizing a Niche Opportunity

The European construction industry is undergoing a mandatory transition toward sustainability, creating a durable and growing demand for advanced building materials that can also generate energy. Establishing a BIPV production facility in Slovakia is a strategic, cost-effective, and logistically sound opportunity to meet this demand.

For the savvy entrepreneur, this is not about competing in the crowded market for standard solar panels. It’s about capturing a high-value niche, building a business on specialized technology and client collaboration, and capitalizing on a market shaped by long-term regulatory certainty.