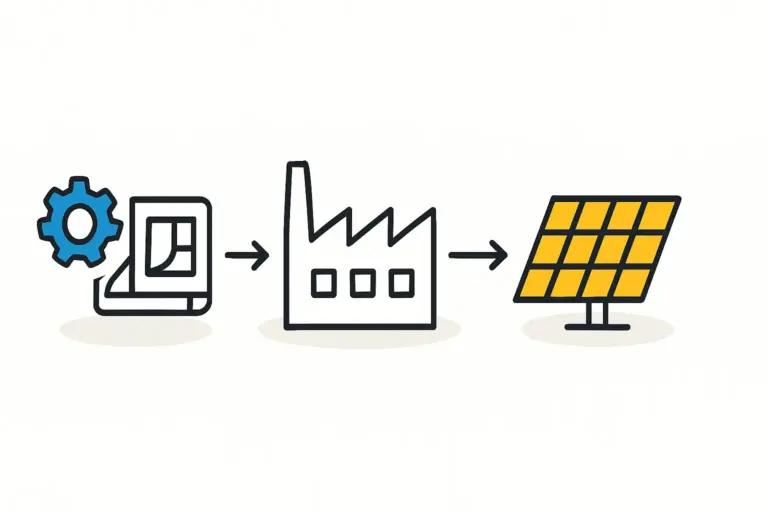

An investor finalizes a robust business plan for a new solar module factory. The technology has been selected, financing is secured, and the target market—the European Union—is ready. But a formidable barrier looms: a dense, evolving set of EU regulations governing everything from energy efficiency to the carbon footprint of each module. Suddenly, market access is no longer a given but a complex challenge.

For entrepreneurs looking to enter the European solar market, understanding regulations like the EU Ecodesign and Energy Labelling frameworks is not just a matter of compliance but a critical part of strategic planning. These rules determine which products can be sold within the world’s largest single market.

This article explains these crucial regulations and outlines why establishing a manufacturing base in an EU member state like Slovenia provides a distinct advantage in this complex landscape.

Understanding the EU Regulatory Landscape

Beginning in the third quarter of 2025, the European Union will implement a new suite of regulations for photovoltaic modules. These rules are designed to promote sustainability, empower consumers, and ensure that products sold in the EU meet high environmental and performance standards. The two core components of this framework are the Ecodesign Regulation and the Energy Labelling Regulation.

The Ecodesign Regulation: Setting the Standard

The Ecodesign Regulation ((EU) 2023/1669) establishes mandatory minimum requirements for the environmental performance of solar modules. It goes beyond just how much energy a panel produces to consider how it is designed, manufactured, and managed at the end of its life. The goal is to push the market toward more durable, reliable, and sustainable products, including new requirements for reparability and the availability of spare parts to ensure modules can be maintained rather than discarded.

The Energy Labelling Regulation: Providing Transparency

The Energy Labelling Regulation ((EU) 2023/1668) aims to provide consumers and installers with clear, comparable information. It introduces a familiar A-to-G energy efficiency scale, similar to those seen on household appliances. Every module sold in the EU will require a label displaying its efficiency class, allowing for straightforward comparisons. This transparency empowers buyers to make informed decisions based on performance, which in turn encourages manufacturers to innovate and improve efficiency.

The Slovenian Advantage for EU Market Access

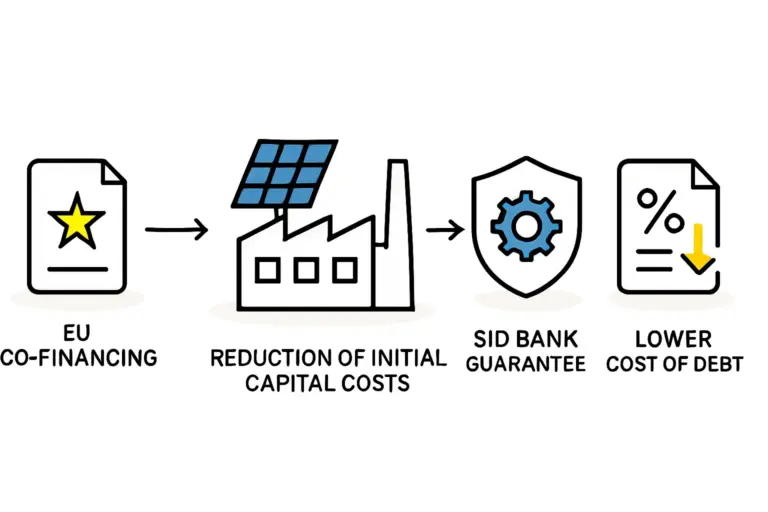

For international businesses, the choice of factory location has profound implications for regulatory compliance. Manufacturing within the EU—particularly in a country like Slovenia—can transform the challenge of compliance into a strategic asset.

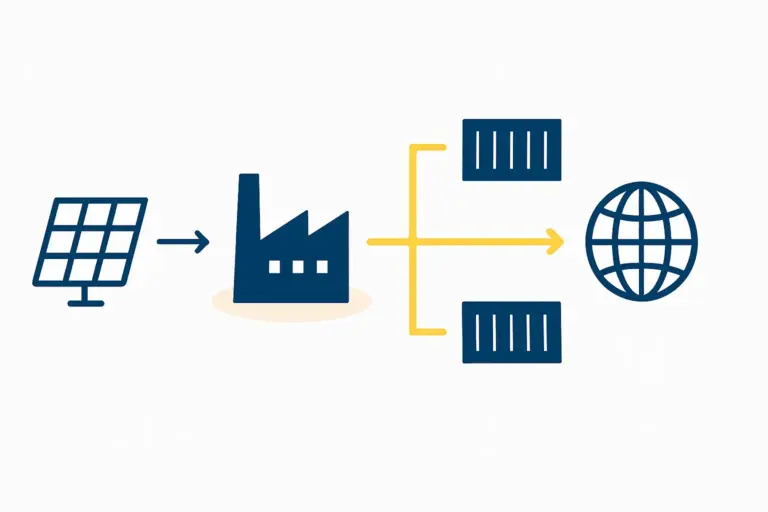

A factory established in Slovenia is, by definition, an EU-based manufacturer. Its products carry a ‘Made in EU’ designation, which fundamentally streamlines market access. This contrasts sharply with the process for manufacturers outside the bloc, who must navigate complex import procedures, third-country certifications, and potential tariffs.

Furthermore, an EU location offers direct access to the ecosystem required for compliance, including accredited testing laboratories, notified bodies for certification, and consultants who specialize in EU regulations. Experience from multiple J.v.G. turnkey projects shows that proximity to this expertise significantly reduces logistical hurdles and accelerates time-to-market. For entrepreneurs considering investing in a solar factory in Slovenia, this built-in advantage is a critical factor for long-term success.

Key Requirements of the New Regulations

The new EU frameworks introduce several specific requirements that manufacturers must meet. These obligations go far beyond traditional performance metrics and require a holistic approach to product design and data management.

Ecodesign Requirements: Beyond Just Efficiency

The Ecodesign rules mandate a broader view of a product’s lifecycle and environmental impact. Key considerations include:

- Durability and Reliability: Modules must be designed and proven to withstand specific environmental stresses, ensuring a long operational life.

- Reparability: For the first time, regulations require that components like junction boxes and connectors be designed for replacement, extending the module’s useful life.

- Recyclability and Material Information: Manufacturers must provide detailed information on the materials used, including the percentage of recycled content. This data will eventually feed into a ‘Digital Product Passport’—a comprehensive record of a product’s lifecycle.

- Carbon Footprint Declaration: A mandatory declaration of the product’s carbon footprint will be required, calculated according to a standardized EU methodology—creating a significant data collection and verification challenge.

Energy Labelling: Communicating Performance

The energy label serves as a public-facing summary of a module’s key characteristics.

- The A–G Scale: This intuitive scale classifies a module’s energy efficiency, making it easy for customers to compare products at a glance.

- QR Code to EPREL: Each label will feature a QR code that links directly to the European Product Registry for Energy Labelling (EPREL). This public database contains detailed technical information submitted by the manufacturer, ensuring a high degree of market transparency.

Practical Steps for Compliance from a Slovenian Base

Achieving compliance is a systematic process that must be integrated into operations from the very beginning.

-

Product Design and Development: Compliance starts on the drawing board. Choices about materials, cell technology, and component design must all be made with Ecodesign requirements in mind. A comprehensive understanding of the solar panel manufacturing process is essential for embedding these principles from the outset.

-

Sourcing Compliant Materials: An EU-based supply chain offers a significant advantage. Suppliers within the EU are themselves subject to regulations like REACH for chemicals, which simplifies the documentation needed to prove compliance for the final product.

-

Technical Documentation and Testing: Manufacturers must compile a detailed technical file containing all test reports, design specifications, and calculation methodologies (like those for the carbon footprint). Using accredited labs within the EU streamlines this validation process.

-

CE Marking and Declaration of Conformity: The final step before placing a product on the market is affixing the CE mark. This symbol is the manufacturer’s official declaration that the product meets all applicable EU health, safety, and environmental protection legislation.

The entire certification pathway, from initial testing to final approval, can take several months. Starting this process from within the EU can de-risk and simplify these critical steps compared to managing them as a third-country exporter.

Frequently Asked Questions (FAQ)

What is the primary difference between Ecodesign and Energy Labelling?

Ecodesign sets mandatory minimum performance standards that products must meet to be sold at all (a ‘push’ mechanism). Energy Labelling provides transparent information to consumers to help them choose the best-performing products, driving the market toward higher efficiency (a ‘pull’ mechanism).

Do these regulations apply to modules manufactured in the EU but sold elsewhere?

No, these specific regulations apply only to products ‘placed on the market’ within the European Union. However, they are widely seen as setting a new global benchmark for quality and sustainability that other regions may adopt in the future.

What is a ‘Declaration of Conformity’?

This is a formal, legally binding document signed by the manufacturer declaring that the specified product fully conforms to all relevant EU regulations and standards. It is a prerequisite for applying the CE mark.

How does the carbon footprint requirement affect material sourcing?

It creates a strong incentive to source materials from suppliers with a lower carbon footprint. This often favors regional supply chains where transportation emissions are lower and suppliers use cleaner energy grids. A turnkey solar manufacturing line can be configured from the start with equipment and processes optimized to minimize the factory’s own carbon footprint, simplifying this reporting requirement.

Planning for a Compliant Future

The EU’s new Ecodesign and Energy Labelling regulations represent a significant shift in the solar industry, moving the focus from pure performance to a more holistic view of sustainability and transparency. While these rules present a complex challenge, they also create an opportunity for well-prepared manufacturers to differentiate themselves on quality and environmental responsibility.

By establishing a manufacturing base within the EU, such as in Slovenia, entrepreneurs can transform this regulatory hurdle into a strategic advantage. This approach provides a clear, streamlined path to the vast European market, builds credibility, and positions the operation for long-term success in an increasingly demanding global landscape. The key is to integrate compliance into the business plan from day one, ensuring that every decision—from factory location to material sourcing—is made with a clear understanding of the road ahead.