An entrepreneur secures funding, finalizes the factory layout, and sets a timeline for equipment delivery. Everything seems on track—until a critical question emerges, often late in the process: Who will operate the sophisticated machinery? In many regions fueling the solar boom, the biggest bottleneck isn’t capital or demand, but finding a skilled technical workforce.

The global solar industry is expanding at an unprecedented rate. Projections from the International Renewable Energy Agency (IRENA) suggest the sector could employ over 10 million people by 2030. This immense opportunity also presents a substantial challenge for new entrants, especially in markets without an established solar manufacturing ecosystem.

In these regions, finding experienced local personnel is nearly impossible. This article outlines three practical, field-proven models for developing a capable team from the ground up.

The Core Challenge: The Skilled Labor Paradox

New solar manufacturers face a paradox: the regions with the greatest potential for solar energy growth often have the smallest pool of experienced technicians. The required skills are specific, spanning machine operation, electronics, quality assurance, and preventative maintenance.

A recent industry analysis shows a global shortage of trained solar technicians is already impacting project timelines and quality, a systemic issue for a rapidly growing industry. For a new factory owner, simply trying to hire a full team of experienced staff is often not viable. The solution, therefore, lies not in finding talent, but in creating it.

Three Proven Models for Workforce Development

Launching a solar module factory in a region with a limited labor pool requires a deliberate strategy for knowledge transfer and skill development. This isn’t an obstacle to overcome; it’s a core part of the initial business plan. The following models have been successfully implemented in turnkey projects across Africa, the Middle East, and Latin America.

Model 1: The ‘Train the Trainer’ Approach

This foundational strategy begins with identifying a small core team of local talent—typically two to four individuals with backgrounds in engineering, electronics, or industrial maintenance. This team is then sent to a specialized facility for an intensive, hands-on training program.

Over several weeks, they learn the entire production process, from machine calibration to quality control and troubleshooting. They are trained not just to be operators, but to become instructors. Upon their return, this core group forms the foundation of the factory’s internal training program, responsible for onboarding and developing all new local hires.

Business Benefits:

- Knowledge Ownership: Critical operational knowledge is embedded within the local team from day one.

- Cost-Effectiveness: It is more financially viable to train a small group intensively than to send a large team abroad for basic training.

- Scalability: Creates a sustainable, in-house system for training future employees as the factory expands.

Model 2: The Expatriate Leadership and Knowledge Transfer Model

For the first 12 to 24 months of operation, bringing in one or two experienced expatriate production managers or senior engineers can be highly effective. Their primary objective isn’t just to run the production line, but to execute a structured knowledge transfer plan.

Their key performance indicators should be tied directly to training their local successors. This model ensures that from the moment the solar production line equipment is commissioned, best practices for operation, safety, and maintenance are established. The expatriate’s role, essentially, is to work themselves out of a job by creating a self-sufficient local management team.

Model 3: The Technical Partnership with Equipment Suppliers

A reliable equipment supplier is more than a vendor; they are a critical technical partner in workforce development. When evaluating a turnkey solar panel production line, the scope and quality of the included training program should be a major consideration.

In successful turnkey projects, for example, the supplier’s engineers remain on-site for several weeks after machinery installation. During this crucial phase, they work side-by-side with newly hired local operators, providing direct, hands-on instruction on the machines. This approach ensures the local team learns from the experts who designed and built the equipment, dramatically shortening the learning curve.

A Phased Approach to Building Long-Term Capability

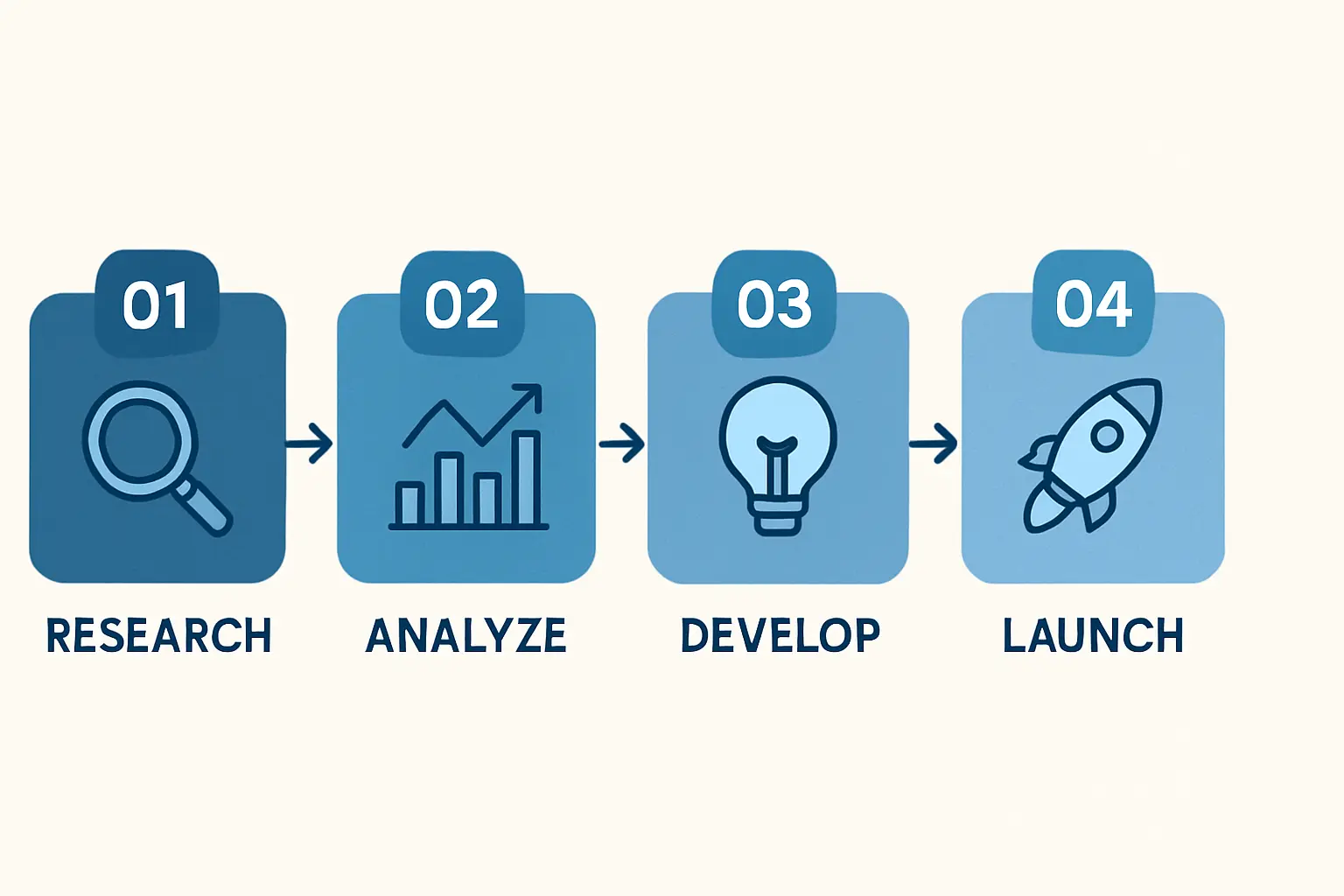

These three models are not mutually exclusive; they work best when integrated into a phased workforce development plan aligned with the factory’s launch timeline.

- Phase 1 (6-9 Months Pre-Launch): Select the core team and initiate the ‘Train the Trainer’ program (Model 1). This happens concurrently with factory construction and equipment manufacturing.

- Phase 2 (Launch and Ramp-Up): The equipment supplier’s technicians arrive for installation and commissioning, leading the initial on-site training (Model 3). If part of the plan, expatriate managers also arrive to establish operational workflows (Model 2).

- Phase 3 (Steady-State Operation): The internally certified trainers (from Model 1) take over all new-hire training. The focus shifts to continuous improvement and upskilling to enhance efficiency and product quality, a step that is vital for long-term competitiveness.

Frequently Asked Questions (FAQ)

What is the ideal background for the first trainees?

Finding individuals with direct solar experience isn’t necessary. The best candidates often have a technical diploma or experience as electricians, mechanics, or machine operators in other manufacturing sectors. A strong work ethic, problem-solving skills, and an ability to learn are more important than prior industry knowledge.

How long does it take to train a machine operator?

A new operator can typically learn the basic functions of a machine like a stringer or laminator within two to three weeks of focused training. However, achieving true proficiency—including the ability to perform minor troubleshooting and adjustments—usually takes three to six months of on-the-job experience.

Is it necessary to hire managers with prior solar experience?

For a top production management role, an experienced manager from any complex manufacturing industry can be very successful if supported by a technical specialist. The core team trained under Model 1 can serve as these specialists. General management and organizational skills are often more critical than specific solar panel knowledge at the senior level.

What is the typical team size for a 20-50 MW factory?

A semi-automated production line with an annual capacity of 20 to 50 MW typically requires approximately 25 to 30 employees per shift. This includes machine operators, quality control inspectors, material handlers, and a maintenance technician.

The Path Forward: From Labor Challenge to Competitive Advantage

Building a skilled workforce in a limited labor market is not a barrier to entry. It is a strategic investment that creates a significant and sustainable competitive advantage. A well-trained, motivated local team is the foundation for producing high-quality solar modules, controlling operational costs, and building a respected brand in your new market.

Detailed workforce planning is fundamental to any comprehensive business plan for solar manufacturing. For entrepreneurs seeking a structured framework for this and other aspects of factory planning, educational resources such as the pvknowhow.com e-course can provide a clear roadmap.