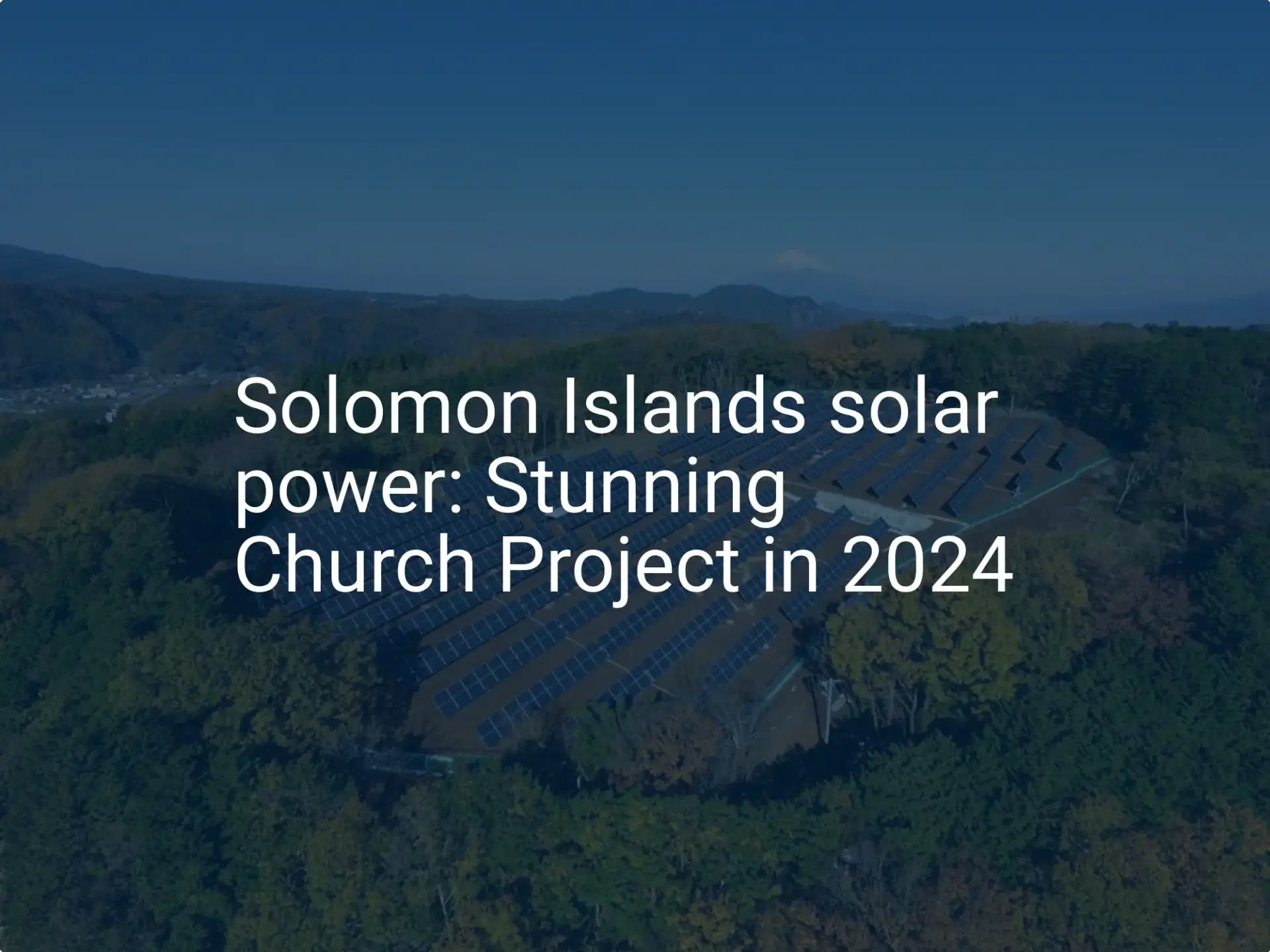

The Solomon Islands presents a compelling paradox for energy entrepreneurs: a nation blessed with abundant sunshine where businesses and residents face some of the highest electricity costs in the world, often exceeding US$0.60 per kilowatt-hour. This gap between natural resources and energy affordability creates a significant opportunity for local solar module manufacturing.

However, developing a viable financial model for a small-to-medium-scale (5-20MW) assembly plant in this unique environment requires more than standard templates. Generic cost assumptions from mainland Asia or Europe will lead to inaccurate projections. Success hinges on a granular understanding of the specific local cost factors that shape a project’s profitability and timeline. This article outlines the critical variables that demand close attention when building a financial plan for a solar factory in the Solomon Islands.

The Business Case: Why Manufacture Solar Modules in the Solomon Islands?

Before delving into costs, it’s important to understand the powerful drivers behind the business case. The high price and unreliability of the national grid create a ready market for alternative power solutions, and local manufacturing offers distinct advantages over simply importing finished modules:

- Reduced Logistics Costs: Importing raw materials in bulk is typically more cost-effective than shipping fragile, fully assembled solar panels.

- Energy Security: Local production contributes to national energy independence, a strategic priority for the government.

- Economic Diversification: With traditional sectors like logging in decline, manufacturing presents a path toward sustainable economic development and job creation.

A locally produced solar module can be highly competitive, but only if the financial model accurately reflects the on-the-ground operational realities.

Deconstructing the Financial Model: Beyond Standard CAPEX Assumptions

An effective financial model is more than a list of machines; it is a comprehensive forecast of all capital and operational expenditures, with special attention paid to local variables. For the Solomon Islands, these variables fall into three critical areas: land and infrastructure, logistics and imports, and human capital.

Based on experience from J.v.G. Technology turnkey projects in emerging markets, entrepreneurs often underestimate these ‘soft’ costs, which can have a greater impact on the budget than the production equipment itself.

Critical Cost Variable 1: Land Acquisition and Site Preparation

The land is the foundation of any factory. In the Solomon Islands, securing a suitable site involves complexities not found in many other parts of the world.

The Complexity of Customary Land Tenure

Approximately 85-90% of land in the Solomon Islands is held under customary tenure, meaning it is owned by clans or tribes rather than by individuals with a single title deed. This has profound implications for a business plan:

- Negotiation Timelines: Leasing or acquiring customary land requires lengthy negotiations with multiple stakeholders, including community elders and family members. A prudent financial model should budget for a 6- to 12-month period for these discussions and legal formalities.

- Legal Costs: Engaging legal counsel with specific expertise in customary land law is non-negotiable and represents a significant upfront project cost.

- Long-Term Stability: A secure, long-term lease agreement is fundamental to securing financing and ensuring operational stability.

Infrastructure and Utility Connection Costs

Once a site is secured, its readiness for industrial use cannot be assumed. The financial model must also include provisions for:

- Site Works: Costs for clearing, grading, and building secure perimeter fencing.

- Access Roads: Ensuring all-weather access for trucks delivering 40-foot containers.

- Utility Connections: Investigating the cost and timeline for establishing a stable, high-capacity connection to the electricity grid and a reliable water source is a crucial early step, as these can be substantial. Given the high local electricity tariffs, many projects also factor in a dedicated solar power system for the factory itself to control operational costs.

Critical Cost Variable 2: Logistics, Imports, and Duties

As an island nation, the Solomon Islands is entirely dependent on sea freight to import machinery and raw materials—a logistical chain that introduces significant costs and risks.

The True Cost of Importing Production Machinery

The quoted price for a laminator or solar cell tester is only the beginning. A realistic financial model must account for the fully-landed cost, which includes:

- Ocean Freight: Shipping a 40-foot container from a manufacturing hub in Asia to Honiara can range from US$5,000 to US$10,000 or more, depending on global market conditions.

- Insurance: Comprehensive transit insurance is essential to protect the capital investment.

- Import Duties: Tariffs on capital goods can be a significant percentage (e.g., 10-20%) of the equipment value. This must be confirmed with local customs authorities, as potential exemptions for renewable energy projects may exist.

- Onshore Handling: Costs for port fees, customs clearance, and transportation from the port to the factory site.

Securing the Raw Material Supply Chain

The ongoing operation of the factory depends on a steady flow of imported raw materials like solar cells, glass, EVA encapsulant, and aluminum frames. From day one, foundational planning for how to start a solar module factory must account for these logistical realities. To mitigate the risk of production stoppages due to shipping delays, the business plan should allocate sufficient working capital to maintain a larger-than-usual inventory buffer—perhaps equivalent to 3 to 6 months of production needs.

Critical Cost Variable 3: Labor and Technical Expertise

While general labor may be readily available, the specialized skills required to operate and maintain solar module manufacturing equipment are scarce in the Solomon Islands.

Bridging the Skills Gap

A successful operation must invest heavily in human capital. The financial model needs to include line items for:

- Comprehensive Training Programs: Budgeting for on-site training by the equipment supplier is crucial. This is a common challenge, which is why a comprehensive turnkey solar manufacturing line often includes training protocols to address this very issue, ensuring local staff can manage day-to-day operations and basic maintenance.

- Knowledge Transfer: The long-term goal is to build a self-sufficient local team. This requires a structured plan for transferring knowledge from initial expatriate experts to local engineers and technicians.

The Hidden Costs of Expatriate Staff

For the first one to two years, the project will likely require one or more expatriate managers or senior engineers to oversee setup, commissioning, and quality control. The model’s operational expenditure (OPEX) section must account for their total cost of employment, including not just salaries but also housing, international travel, and visa processing fees.

Building a Resilient Financial Forecast

A financial model that honestly incorporates these local variables will be far more robust and credible to investors and lenders. Rather than being a discouraging exercise, this detailed planning is the first step toward mitigating risk.

Entrepreneurs should stress-test their models against delays in land acquisition, fluctuations in shipping costs, and higher-than-expected training requirements. These are the granular details that transform a standard template into a bankable solar panel manufacturing business plan.

Frequently Asked Questions (FAQ)

What is a realistic initial investment for a 5-10MW plant in this context?

While highly dependent on equipment choice and site conditions, investors should anticipate a higher initial outlay than in mainland Asia. Due to logistics, site preparation, and necessary working capital buffers, an illustrative range of US$1.5 million to US$3 million for a semi-automated line is a reasonable starting point for detailed planning.

How long does it take to become operational in the Solomon Islands?

Assuming financing is in place, a realistic timeline from project start to first module production is between 12 and 18 months. The most significant variable is the time required for land negotiation and acquisition.

Are there government incentives for solar manufacturing in the Solomon Islands?

The government has expressed strong support for renewable energy. Entrepreneurs must conduct thorough due diligence with relevant authorities like the Ministry of Finance and Treasury and Investment Solomon to identify specific incentives, such as tax holidays or import duty exemptions, that may apply to their project.

Can a factory be profitable with such high operating costs?

Yes, because the alternatives are even more expensive. The high local cost of electricity and imported solar modules creates a favorable price environment for a local manufacturer that can effectively manage the costs outlined above.

Conclusion: From Concept to a Bankable Project

The opportunity to establish a solar module assembly plant in the Solomon Islands is significant, driven by fundamental market needs. However, success isn’t guaranteed by the opportunity alone; it comes from meticulous and localized planning.

A bankable project rests on a financial model that replaces generic assumptions with well-researched local data on land, logistics, and labor. By addressing these complexities directly, an entrepreneur can build a resilient business prepared for the local operating environment and positioned to play a key role in the nation’s energy future. Educational platforms like pvknowhow.com offer structured guidance to help entrepreneurs navigate these challenges with confidence.