Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Investment Case: A Solar Factory for B-BBEE Level 1 Status and REIPPPP Advantage

In South Africa’s competitive Renewable Energy Independent Power Producer Procurement Programme (REIPPPP), a winning bid is rarely determined by price alone. For discerning investors and project developers, non-price criteria—particularly Broad-Based Black Economic Empowerment (B-BBEE) status and local content commitments—have become critical differentiators.

An often-overlooked yet powerful strategy to excel in these areas is to establish a local solar module manufacturing facility. Here, we outline the strategic framework for using a solar factory to achieve a B-BBEE Level 1 rating and create a formidable advantage in REIPPPP tenders. This kind of investment moves beyond simple component supply, becoming a cornerstone of economic development that aligns perfectly with national strategic goals.

Understanding the Strategic Levers: REIPPPP and B-BBEE

To appreciate the full scope of this opportunity, it’s essential to understand the two core pillars of South Africa’s energy procurement policy.

The Renewable Energy Independent Power Producer Procurement Programme (REIPPPP)

Launched to increase the share of renewable energy in the national grid, the REIPPPP is the primary mechanism through which the government procures power from private developers. With a stated goal of securing over 2,200 MW from solar PV by 2030, the program represents a significant, long-term opportunity.

However, a key objective of the REIPPPP is to drive local industrialization and job creation. As a result, bid evaluations place substantial weight on factors beyond the cost of electricity, including job creation, local investment, and community development.

Broad-Based Black Economic Empowerment (B-BBEE)

B-BBEE is a government policy designed to redress the economic inequalities of the past. It is not simply about ownership but a comprehensive scorecard that measures a company’s contribution across five key areas:

- Ownership: The percentage of the business owned by black people.

- Management Control: The representation of black people in senior management and board positions.

- Skills Development: Investment in training and developing black employees.

- Enterprise and Supplier Development (ESD): Supporting and buying from black-owned businesses.

- Socio-Economic Development: Contributions to community-based initiatives.

A company’s performance across these elements results in a B-BBEE level, with Level 1 being the highest possible rating. In any government tender, including the REIPPPP, a higher B-BBEE level provides a significant competitive advantage.

The Strategic Nexus: How a Solar Factory Maximizes B-BBEE Scores

Establishing a solar module assembly plant is one of the most direct and impactful ways to achieve a top-tier B-BBEE rating while simultaneously fulfilling REIPPPP’s localization mandates. The operation of a factory naturally aligns with every element of the B-BBEE scorecard.

A Direct Path to High Scores

-

Ownership: The factory can be structured from inception with a qualifying ownership model, immediately securing maximum points in this critical, high-weighting category.

-

Management Control & Skills Development: A factory necessitates a local workforce. This creates opportunities for management roles and provides a clear framework for implementing skills development programs, from shop-floor technicians to plant managers. Training becomes a core operational necessity, not an abstract expense.

-

Enterprise and Supplier Development (ESD): A manufacturing plant requires a local supply chain that includes everything from security services and logistics to raw material packaging and equipment maintenance. This provides a powerful mechanism to procure from and develop smaller, black-owned enterprises, directly contributing to the ESD element. Based on experience from European PV manufacturer’s turnkey projects, a factory with an annual capacity of 20-50 MW can sustain a workforce of 25-40 employees and create a ripple effect in the local supplier economy.

-

Local Content: Beyond the B-BBEE score, the factory directly addresses the increasing local content thresholds required by the Department of Trade, Industry and Competition (DTIC). Assembled modules are designated as having high local value, a key requirement for preferred bidder status.

Integrating these elements transforms a solar factory from a production asset into a strategic tool for achieving Level 1 B-BBEE status, making any associated REIPPPP bid significantly more competitive.

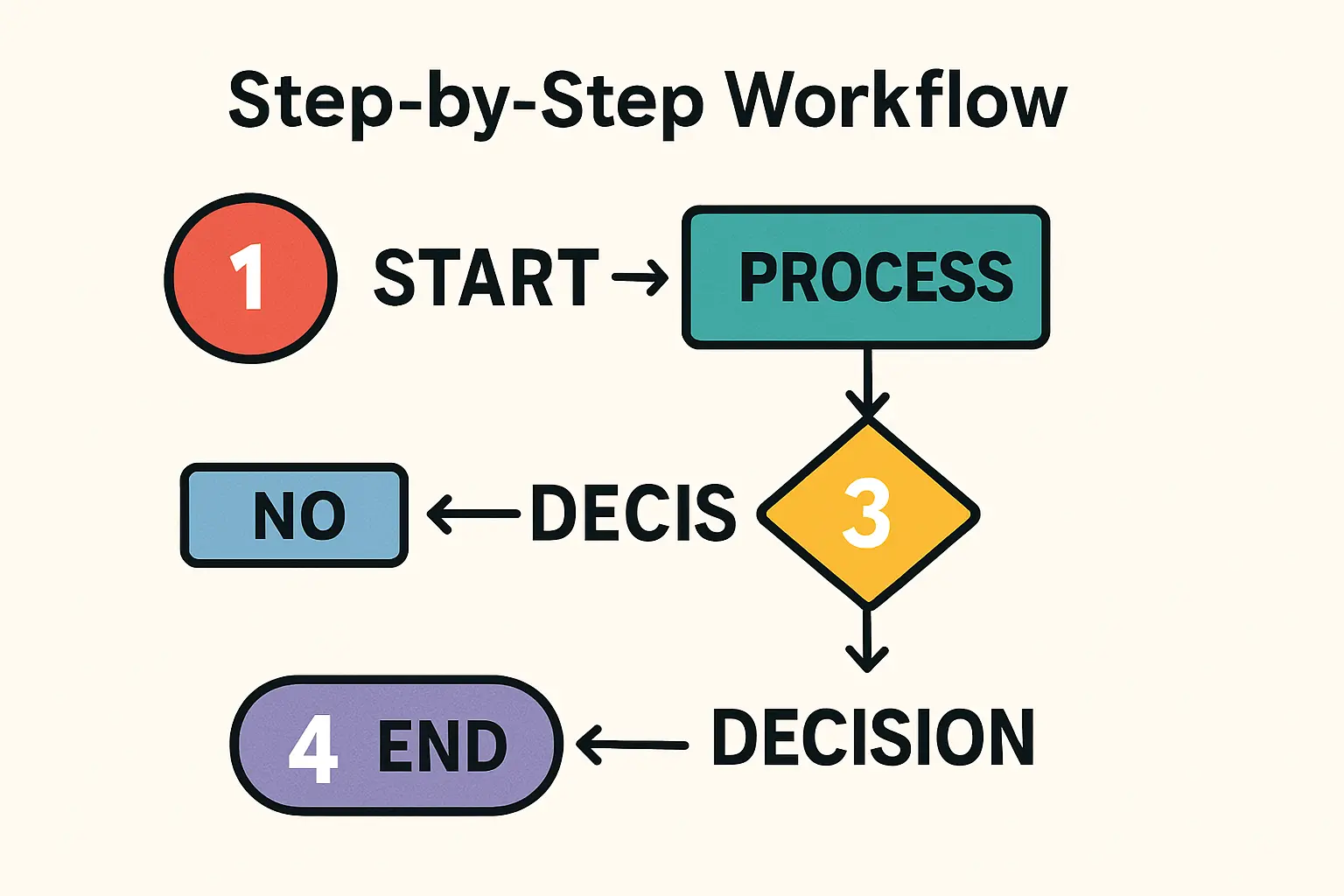

A Framework for Execution: The Turnkey Factory Approach

For an entrepreneur or investor without a background in photovoltaic engineering, the prospect of setting up a manufacturing plant can seem daunting. This is where a structured, turnkey approach becomes essential. A turnkey solution provides a complete, ready-to-operate production line, including machinery, process engineering, staff training, and initial operational support.

This model allows the investor to focus on strategic business aspects—securing financing, building the B-BBEE structure, and developing the route to market—while relying on an experienced technical partner to manage the complexities of plant setup.

A partnership with an established engineering firm like an EU-based photovoltaic manufacturing solution partner provides access to decades of experience. The experienced European turnkey engineering team, founders of expert-led solar project architecture and modeling, have been involved in solar technology since the 1990s, offering a depth of knowledge that de-risks the project’s technical execution. This partnership enables investors to enter the market confidently, guided by proven processes and reliable technology. To understand this model in more detail, it helps to explore what a turnkey solar panel factory is.

Frequently Asked Questions for the Aspiring Industrialist

What is a realistic investment for a semi-automated factory in South Africa?

A typical investment for a 20 MW to 50 MW semi-automated production line involves several components. While a detailed solar panel manufacturing business plan is necessary for precise figures, initial capital expenditure for machinery, logistics, and commissioning often falls within a specific range. More detail on equipment investment can be found by researching the solar panel production line cost.

How long does it take from the investment decision to the first certified module?

With a well-defined project plan and an experienced turnkey partner, a production line can be operational in under 12 months. This timeline includes factory planning, machine procurement, installation, commissioning, and staff training.

Do I need to be a solar engineer to run a successful factory?

No. The investor’s role is that of a business leader and strategist. The turnkey partner provides the technical expertise, machine calibration, process workflows, and initial training for the local management and engineering team. Resources like pvknowhow.com also provide structured e-courses to help bridge this knowledge gap during the planning phase.

How does a local factory compete with large-scale international imports?

Competition is not based solely on unit price. A local factory competes on strategic grounds. Its products provide REIPPPP bidders with the local content and B-BBEE credentials that imported modules cannot offer. This creates a protected, high-value domestic market for the factory’s output, especially for utility-scale projects.

Conclusion: From Manufacturer to Strategic National Partner

Investing in a solar module factory in South Africa is more than an industrial venture; it is a strategic move that positions an enterprise at the heart of the country’s Just Energy Transition. It provides a clear and defensible pathway to achieving a B-BBEE Level 1 rating, creating a decisive competitive advantage in the multi-billion-rand REIPPPP market.

Adopting a turnkey approach with a seasoned technical partner allows investors to mitigate execution risk and focus on harnessing this unique strategic opportunity. The result is a commercially viable business that not only generates returns but also contributes directly to national goals of industrialization, job creation, and sustainable economic empowerment.

Download the B-BBEE & REIPPPP Solar Investment Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.