An entrepreneur planning to establish a solar module factory in Sudan is stepping into a landscape of immense opportunity. With 3,000 to 3,500 hours of sunshine annually and an electrification rate of around 35%, domestic demand for solar energy is substantial and growing. Government targets for renewable energy only add to this potential. However, the venture’s success hinges on a critical decision made long before the first module is produced: where will the raw materials come from?

This decision—whether to import all components or develop a local and regional supply chain—directly impacts cost, operational stability, and long-term profitability. This article offers a foundational analysis for business professionals exploring this crucial aspect of solar manufacturing in Sudan.

The Core Dilemma: Sourcing Your Bill of Materials (BOM)

The ‘Bill of Materials,’ or BOM, is the list of all raw materials required to build a single solar module. These materials typically account for 70-80% of the final product’s cost, making their procurement the most significant operational expense. For a new factory in Sudan, the sourcing strategy boils down to two main paths: a complete import model or a hybrid model that incorporates local and regional suppliers.

Analyzing the Import-Centric Approach

The most straightforward path, especially for a new operation, is to import all necessary components from established global hubs, primarily in Asia.

Advantages:

- Established Quality: Suppliers have years of experience and adhere to international certification standards (like IEC and UL).

- Wide Selection: Access to the latest technologies and a wide range of component specifications.

- Simplified Procurement: Dealing with a few large, experienced suppliers can streamline initial purchasing.

Challenges for a Sudanese Operation:

- Logistical Complexity: Sea freight to Sudan arrives exclusively through Port Sudan, which can create significant logistical bottlenecks and delays. These delays can halt production entirely.

- Foreign Currency Exposure: Importing requires consistent access to foreign currency (primarily US dollars). Given the volatility and accessibility challenges common in many emerging markets, this poses a major financial risk. Global price fluctuations for commodities like aluminum and glass add another layer of uncertainty.

- Long Lead Times: Ocean freight can take several weeks, requiring the factory to hold large amounts of capital in inventory, both in transit and in its warehouse.

This heavy reliance on imports, while initially simpler, can create a fragile business model highly susceptible to external shocks beyond management’s control.

Assessing Local & Regional Sourcing Potential in Sudan

A more resilient and potentially cost-effective long-term strategy involves sourcing some components from within Sudan or from neighboring countries. This requires a careful assessment of what is realistically available versus what must still be imported.

Key Components Under Review

An examination of a solar module’s main components reveals their sourcing feasibility.

Aluminum Frames

Anodized aluminum frames protect the module’s edges and provide structural stability. The core technology is aluminum extrusion, a relatively common industrial process.

- Local Potential: An investigation into Sudan’s existing industrial capacity is the first step. The goal is to determine if local companies can produce high-quality aluminum profiles, considering not just extrusion capability but also the ability to perform precision cutting, drilling, and high-quality anodizing for weather resistance.

- Regional Potential: Neighboring countries like Egypt have a well-developed aluminum industry. Sourcing from a regional partner could significantly reduce shipping times and costs compared to importing from Asia.

Solar Glass

This is not standard window glass. Solar glass must be low-iron and tempered to maximize light transmission and withstand harsh environmental conditions.

- Local Potential: Manufacturing true low-iron solar glass is a highly specialized and capital-intensive process. It is highly unlikely that a supplier meeting the required specifications currently operates within Sudan.

- Regional Potential: Egypt has emerged as a producer of solar glass, making it a viable regional sourcing option that could offer a significant advantage over transcontinental imports.

Junction Boxes and Connectors

These are specialized, injection-molded plastic components containing bypass diodes and connection cables.

- Local/Regional Potential: While the electronic components (diodes) and specialized cables would almost certainly need to be imported, the plastic housing and final assembly could potentially be localized if a capable plastics industry exists. For initial operations, however, importing complete, certified junction boxes is the most common and reliable approach.

Packaging Materials

Cardboard boxes, corner pieces, and other packaging materials are essential for protecting finished modules during shipping.

- Local Potential: This is the most promising category for local sourcing. Sudan’s existing paper and packaging industry can likely produce these materials to specification, reducing costs and simplifying logistics.

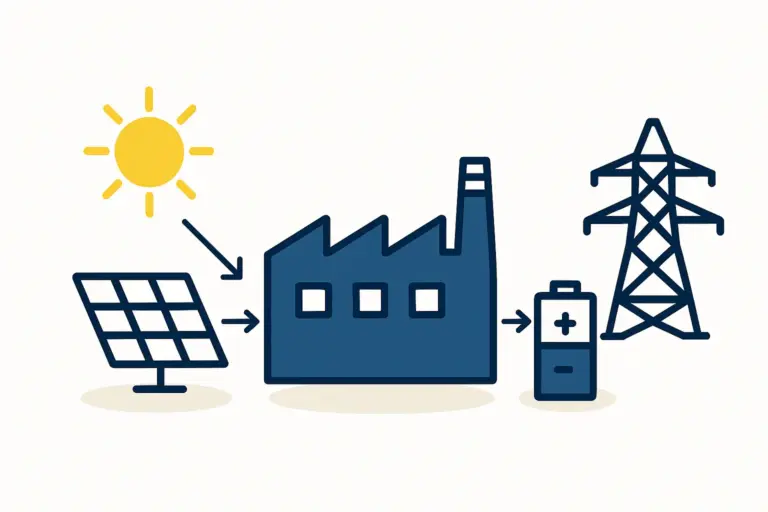

A Hybrid Strategy: The Most Viable Path Forward

For most new solar factories in Sudan, a hybrid model offers the best balance of risk, cost, and quality. This strategy involves identifying which components can be sourced locally or regionally while relying on imports for the most specialized materials.

A typical hybrid model might look like this:

- Import: Solar cells, EVA encapsulant, backsheet, junction boxes, and solar glass (unless a reliable regional supplier is confirmed).

- Source Regionally: Aluminum frames and potentially solar glass (e.g., from Egypt).

- Source Locally: All packaging materials.

The initial investment for a solar factory must include a thorough feasibility study to validate these local and regional supply options. Based on experience from J.v.G. Technology GmbH projects in emerging markets, this early-stage due diligence is critical to developing a robust business plan.

Frequently Asked Questions (FAQ)

What are the most critical components to import at the beginning?

For a new operation, it is wisest to import the most technologically sensitive components: solar cells, EVA encapsulant, backsheets, and certified junction boxes. The quality of these materials directly determines the module’s performance and lifespan.

Which components are easiest to source locally first?

Packaging materials (cardboard, dividers) are almost always the best candidates for immediate local sourcing. They have less technical complexity and offer quick wins in cost reduction and logistical simplification.

How does local sourcing affect quality control?

This approach requires establishing a rigorous inspection process for incoming goods. Your factory must have the equipment and trained personnel to verify that locally sourced materials, such as aluminum frames, meet precise dimensional and material specifications.

Can standard window glass be used for solar modules?

No. Standard glass has a high iron content that gives it a slight green tint, reducing the amount of light that reaches the solar cells and lowering the module’s power output. Solar glass is specifically engineered to be low-iron for maximum light transmission.

Conclusion and Next Steps

The decision between importing and local sourcing is not a simple choice but a strategic process of risk management. While importing everything offers initial simplicity, it exposes a Sudanese solar factory to significant currency and logistical risks. A carefully developed hybrid strategy, leveraging local and regional suppliers where feasible, builds a more resilient and competitive manufacturing operation.

For any serious investor, a thorough supply chain analysis is a mandatory first step. This means identifying and vetting potential local and regional suppliers long before committing capital. Understanding the main equipment in a solar module production line is another crucial step, as your choice of machinery will define your production capabilities and material requirements.

For entrepreneurs embarking on this journey, creating a detailed business plan around a well-researched, realistic sourcing strategy is the foundation for long-term success. A turnkey solar module manufacturing line provider can assist with this critical due diligence as part of the overall project planning.