An investor examining Sudan sees a compelling opportunity.

Africa’s third-largest country benefits from some of the world’s highest solar irradiation levels, averaging 7.5 to 8.5 kWh per square meter daily. Couple this with grid electricity prices around $0.25/kWh and a population where 60% live without reliable power, and the domestic demand for solar energy is undeniable. To encourage investment, the government has also established incentives like the Renewable Energy Act.

Yet, a critical factor often overlooked in initial business plans is human capital. While the market opportunity is clear, the availability of a workforce with specialized experience in photovoltaic (PV) manufacturing is far from certain. This skills gap is not an insurmountable barrier, but rather a strategic challenge. Addressed correctly, it can become a significant competitive advantage. This guide outlines how to build a skilled local workforce from the ground up, transforming potential into a productive reality.

Understanding the Human Capital Landscape in Sudan’s Solar Sector

Sudan presents a paradox for solar investors. On one hand, it has a large, youthful population and comparatively low labor costs, which are attractive fundamentals for any manufacturing venture. On the other, the country faces a shortage of vocational training programs for solar technology and has experienced a ‘brain drain’ of qualified engineers to other regions.

An entrepreneur cannot simply assume that experienced PV technicians will be readily available. The success of a new solar module factory hinges on the investor’s commitment to building and nurturing talent internally. The objective is to establish a systematic process for transferring knowledge and developing skills, creating a self-sustaining and capable local team. This approach transforms a potential weakness into a source of long-term operational stability and community integration.

Core Competencies Required for a Solar Module Factory

A solar module assembly line is a sophisticated environment requiring a team with diverse yet specific skills. While direct PV experience may be rare, foundational competencies can often be found in candidates from other manufacturing or technical fields. A typical factory needs a well-coordinated team across several key roles.

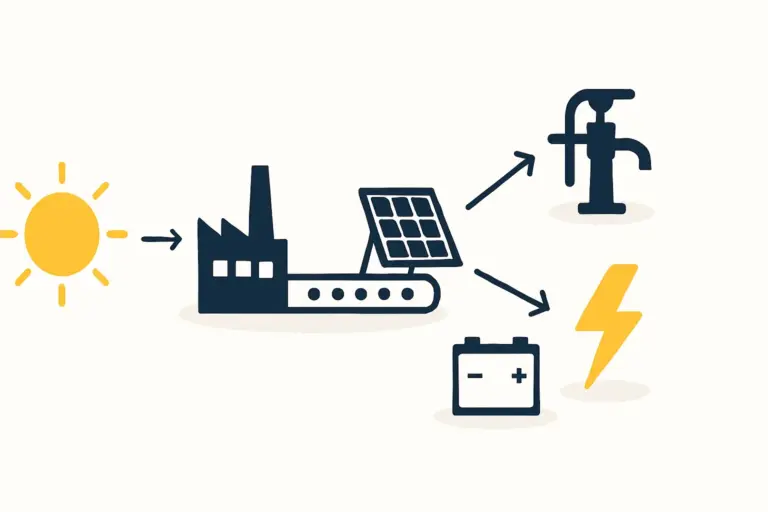

The manufacturing process itself reveals the necessary skills at each stage:

-

Machine Operators: Responsible for the day-to-day operation of specific equipment like stringers, laminators, and testers. This role requires attention to detail, strict adherence to safety protocols, and the ability to follow precise operational procedures.

-

Technicians: These individuals handle machine setup, calibration, routine maintenance, and first-level troubleshooting. A background in mechanics or electronics is highly advantageous.

-

Engineers: Process engineers oversee production flow, optimize machine parameters, and ensure the entire line runs efficiently. Electrical or mechanical engineering graduates are ideal candidates who can be trained in the specifics of PV technology.

-

Quality Control (QC) Specialists: Tasked with inspecting materials and finished products at various stages, from cell testing to final module electroluminescence (EL) imaging. They ensure that every module meets international standards.

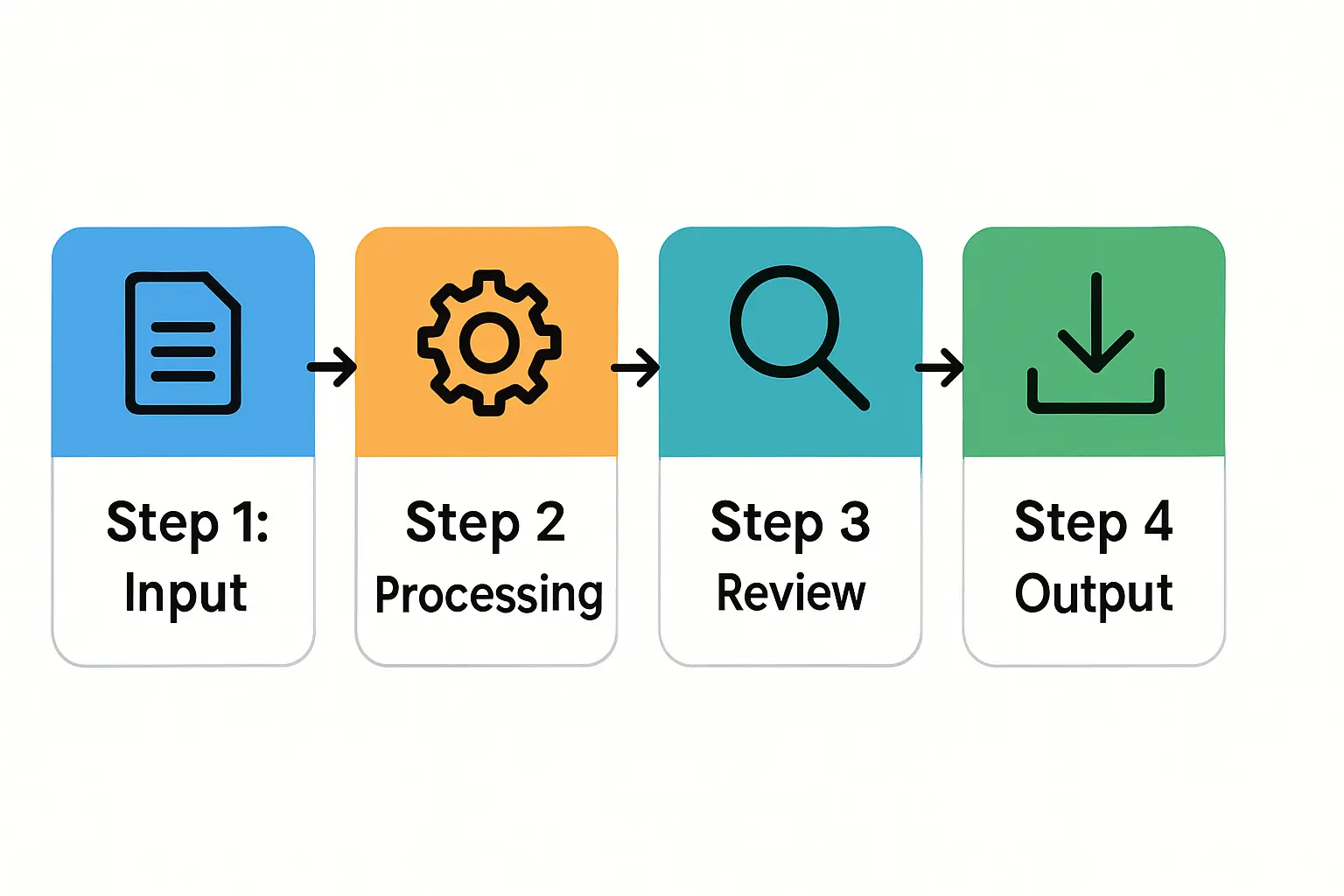

A Blueprint for Building Your Local Solar Workforce

Building a skilled team from scratch requires a structured, phased approach. It’s an investment in people that pays dividends in production quality, efficiency, and operational independence.

Phase 1: Strategic Recruitment and Sourcing

The initial search for talent should focus on aptitude and foundational knowledge rather than specific PV experience. Excellent candidates can be found in:

-

Technical Universities and Vocational Schools: Graduates in electrical engineering, mechanical engineering, and industrial automation provide a strong theoretical base.

-

Existing Manufacturing Industries: Individuals with experience in electronics assembly, automotive, or food processing already understand production line discipline, safety, and quality standards.

-

Military Veterans: Personnel with technical or logistical backgrounds often possess discipline, problem-solving skills, and an ability to work well in structured team environments.

The key is to identify individuals eager to learn, with strong problem-solving abilities and a solid work ethic.

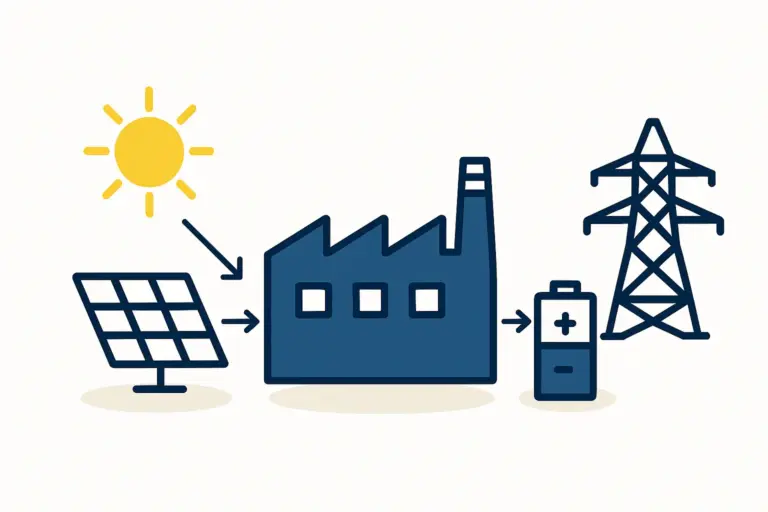

Phase 2: Foundational and On-the-Job Training

Once a core team is recruited, a comprehensive training program is essential, typically led by experienced engineers from the equipment supplier or a third-party consultant. Expert-led training is a key benefit of purchasing a turnkey solar manufacturing line, as it is often integrated into the project scope.

The program should combine classroom theory with extensive hands-on practice, covering the function of each machine, safety procedures, material handling, and the fundamentals of photovoltaic science.

This phase is critical for establishing a culture of quality and precision from day one. Experience from J.v.G. Technology turnkey projects shows this initial, intensive knowledge transfer from external experts to be the most effective way to quickly build a competent local team.

Phase 3: Creating a Sustainable Training Program

The ultimate goal is to create a self-sufficient operation. A ‘Train the Trainer’ model is highly effective. During the initial training, select the most promising local engineers and technicians to become future in-house trainers. They receive advanced instruction and are empowered to onboard new employees as the factory grows.

This creates a sustainable knowledge base within the company and reduces long-term reliance on external experts. A well-structured program evolves with the team.

For long-term success, forging partnerships with local universities or technical colleges can create a steady pipeline of pre-qualified candidates, further cementing the factory’s role in the local economy.

Financial and Operational Considerations

Budgeting for workforce development is as important as budgeting for machinery. These costs must be factored into the initial investment calculations. While this adds to the upfront capital expenditure, it prevents far more costly mistakes, production downtime, and quality issues down the line.

A typical training plan requires a 3- to 6-month period to train the core team before commercial production begins, a timeline that must be factored into the overall project schedule. The physical space for training—including a classroom and safe practice areas—should be incorporated into the initial factory layout and design.

Frequently Asked Questions (FAQ)

How many employees are needed for a small-scale solar factory?

A semi-automated factory with an annual capacity of around 50 MW typically requires a workforce of 25 to 35 employees per shift, including operators, technicians, quality control personnel, and supervisory staff.

Can we hire engineers from other industries?

Absolutely. Mechanical, electrical, and industrial engineers possess the core problem-solving and analytical skills needed. They can adapt to the specifics of solar module manufacturing with a focused, 3-to-6-month training program.

What is the role of an expatriate expert in the long term?

An expatriate expert is crucial for the initial setup, commissioning, and training of the core local team. Their role is to establish international best practices for operations and quality. Over time, as the local team’s expertise grows, the need for on-site expatriate support diminishes, transitioning to a remote advisory role.

How long does it take to train a machine operator?

A new operator can learn the basic functions of a machine like a stringer or laminator within a few weeks. However, achieving true proficiency—the ability to perform basic troubleshooting and understand how their work impacts overall module quality—typically takes three to six months of consistent practice.

Conclusion: Your Workforce as a Competitive Advantage

In a market like Sudan, where the potential for solar energy is immense but the specialized labor pool is just beginning to develop, building your own workforce is not merely a necessity—it is a strategic decision. A well-trained, motivated local team becomes a powerful asset, improving quality, increasing efficiency, and ensuring the long-term sustainability of the operation.

By viewing the skills gap not as a barrier but as an opportunity to build a loyal and capable team, an investor can lay the foundation for a successful and impactful manufacturing venture. With a structured approach to recruitment, training, and continuous development, a world-class production team is an achievable goal. For entrepreneurs planning their entry, resources like the pvknowhow.com e-course provide a valuable framework for addressing these human resource challenges from the earliest stages of planning.