An entrepreneur planning to establish a solar module factory faces a unique irony: the very facility designed to produce renewable energy technology is itself critically dependent on a stable, cost-effective power supply.

In regions like Sudan, where the national grid can be unreliable, securing this power is not merely an operational detail. It is a foundational challenge that can determine the success or failure of the entire venture.

This guide explores how to design a resilient power infrastructure to address this challenge. It examines the feasibility of off-grid and hybrid solutions that leverage a factory’s own solar output, transforming a significant operational risk into a powerful competitive advantage.

The Core Challenge: Grid Instability in Manufacturing

For any manufacturing operation, consistent power is non-negotiable. Unexpected power outages, a documented concern in many developing economies, can lead to costly production downtime, damage sensitive machinery, and a complete loss of output. For a business operating on precise schedules with high-capital equipment, these interruptions pose an unacceptable level of risk.

Traditionally, the fallback solution has been diesel generators. However, this approach presents its own significant drawbacks:

-

High Operational Costs: Volatile fuel prices and logistical challenges in transporting diesel can create unpredictable and escalating operational expenses.

-

Maintenance Demands: Generators require regular, specialized maintenance, adding another layer of complexity and cost.

-

Environmental Impact: For a business built on clean energy, relying on fossil fuels fundamentally misaligns with its core mission.

This reliance on diesel is a temporary fix for a systemic problem, not a sustainable long-term strategy.

Sudan’s Untapped Advantage: Abundant Solar Energy

While grid infrastructure may present a challenge, Sudan has an extraordinary natural resource that offers a direct solution: world-class solar irradiation. With levels ranging from 5.3 to 7.1 kWh/m² per day, the country has one of the highest solar energy potentials globally.

This abundance of sunlight is not just a fortunate circumstance; it is a strategic asset. This means a solar factory in Sudan is ideally positioned to achieve energy independence by harnessing the very resource its products are designed to capture.

Understanding Power Solutions for Your Factory

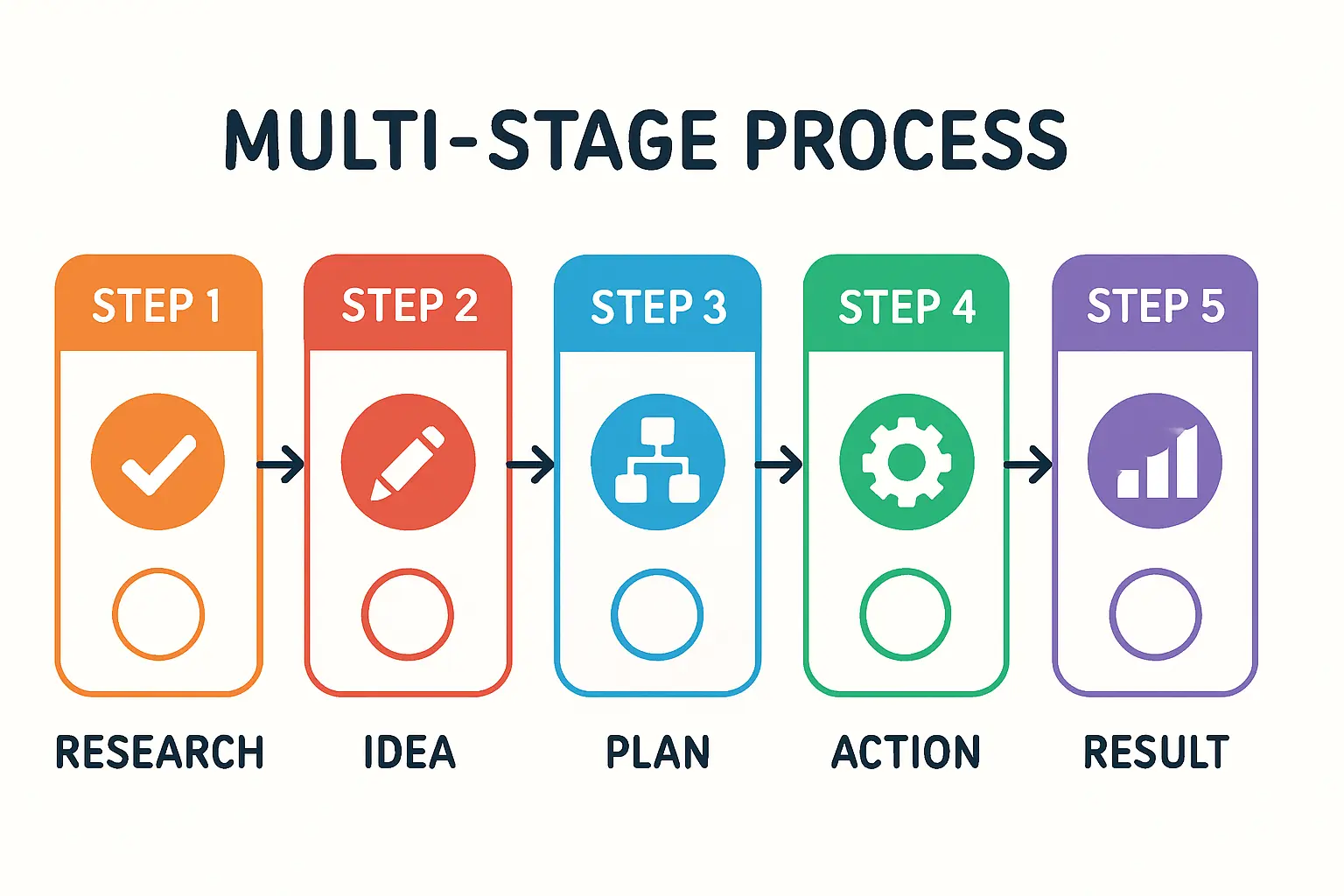

When planning for energy self-sufficiency, two primary models emerge: the fully off-grid system and the more common hybrid system.

The Off-Grid Approach: Complete Energy Independence

A fully off-grid system operates entirely independent of the national utility grid. All power required for the factory is generated on-site, typically through a large solar photovoltaic (PV) array, and stored in a Battery Energy Storage System (BESS) for use overnight or during periods of high demand.

Advantages: Complete immunity from grid blackouts and no ongoing utility bills.

Considerations: This approach requires a substantial initial investment in battery capacity to ensure an uninterrupted power supply, especially through several days of low sunlight.

The Hybrid Approach: The Best of Both Worlds

A hybrid system offers a more flexible and often more practical solution. It combines on-site solar generation and battery storage with a connection to the national grid. A backup diesel generator can also be integrated as a final layer of security.

The system is intelligently managed to prioritize the lowest-cost energy source at any given time:

- Primary Power: The factory runs directly on solar power during the day.

- Energy Storage: Excess solar energy charges the battery system.

- Evening and Night Power: The factory draws power from the charged batteries.

- Grid Backup: If batteries are depleted, the system automatically switches to the grid.

- Final Redundancy: In the rare event of a prolonged grid outage, the backup generator can be activated.

This tiered approach provides maximum reliability while significantly minimizing reliance on the grid and expensive diesel fuel.

Designing a Resilient Power System: A Case Study

The viability of this model is not merely theoretical. Drawing on experience from J.v.G. turnkey projects, a hybrid power system was successfully implemented for a client’s factory in Khartoum, Sudan. The project was designed to provide reliable power for a complete turnkey solar module manufacturing line, mitigating the risks of local grid instability.

The system was sized based on a detailed energy audit of all solar manufacturing equipment and facility operations. The core components included a large-scale PV array, a Battery Energy Storage System (BESS), and smart inverters and a control system to manage energy flow. A key plan was to use some of the first modules produced by the factory itself to expand the array.

The business case was compelling. The initial investment in the hybrid power system had a projected payback period of just 3 to 5 years, a stark contrast to the high ongoing costs of running the factory primarily on diesel generators. This demonstrates that strategic financial planning can turn a necessary infrastructure cost into a high-return investment.

Key Considerations for Your Factory’s Power Infrastructure

Integrating a self-sufficient power system requires careful planning from the earliest stages of the project.

-

Energy Consumption Audit: Before sizing any equipment, a thorough analysis of the factory’s total anticipated energy consumption is essential. This must account for all machinery, lighting, HVAC, and office facilities.

-

System Sizing: The PV array and battery storage must be correctly sized to meet peak demand and provide sufficient autonomy. Undersizing the system creates power shortfalls, defeating its purpose.

-

Physical Footprint: Both solar arrays and battery systems require significant physical space. This factor must be integrated into the factory’s overall site layout and building design from the start.

-

Investment as an Asset: While the initial capital outlay is significant, it should be viewed as an investment in operational certainty and long-term cost reduction, rather than simply an expense.

Frequently Asked Questions (FAQ)

Can the factory use the solar modules it produces to power itself?

Yes, absolutely. This is one of the most significant advantages. Once production begins, the factory can install its own modules to expand its power generation capacity, creating a self-sustaining cycle.

What is the typical lifespan of a battery storage system?

Modern lithium-ion battery systems for industrial use typically have a lifespan of 10 to 15 years or a specific number of charge-discharge cycles, depending on the technology and usage patterns.

How does a hybrid system handle a multi-day grid outage?

During a prolonged outage, the system would rely entirely on solar generation during the day and stored battery power at night. The backup generator would only be used if several consecutive days of heavy cloud cover depleted the batteries.

Is government support available in Sudan for such projects?

Many governments, including Sudan’s, have policies to encourage investment in renewable energy. It is worth investigating potential incentives, tax benefits, or favorable feed-in tariffs as part of the initial business planning.

What are the maintenance requirements for a hybrid system?

PV panels require minimal maintenance, mostly periodic cleaning. The BESS and inverter systems need professional inspection and maintenance following the manufacturer’s schedule, which is significantly less demanding than the upkeep of a diesel generator.

Conclusion: Building a Foundation for Success

For an entrepreneur entering the solar manufacturing space in Sudan, securing a reliable power source is fundamental to success. Rather than viewing the local grid as an insurmountable obstacle, it should be seen as an opportunity to build a truly resilient and cost-efficient operation from the ground up.

A well-designed hybrid power system does more than just keep the lights on. It provides a strategic shield against the price volatility and supply chain disruptions associated with fossil fuels. It also lowers long-term operational costs, strengthens the business’s financial model, and aligns the entire operation with the clean energy mission it promotes.

By planning for energy independence from day one, a new solar factory can establish a robust foundation for long-term growth and profitability.