A common assumption among new entrants to the solar industry is that all solar modules are fundamentally the same. An investor might focus on securing the lowest price per watt, assuming this offers the best competitive advantage. However, in a market like Sudan—where temperatures can exceed 45°C and dust is a constant presence—this approach can lead to significant underperformance and financial disappointment. A module that performs well in a moderate European climate may lose a substantial portion of its output under the intense African sun, eroding the very returns the business was built upon.

Understanding the interplay between technology and climate isn’t merely a technical detail—it is the cornerstone of a successful manufacturing strategy. This article explores why specialized solar module technologies are critical for long-term viability in high-temperature environments like Sudan and offers guidance on selecting a product that delivers sustained performance and builds market trust.

The Challenge: How Extreme Heat and Dust Impact Solar Panel Performance

Solar modules are tested and rated for efficiency under Standard Test Conditions (STC), which specify an ambient temperature of 25°C (77°F). This baseline is useful for comparison but fails to reflect real-world operating conditions in many parts of the world. In Sudan, where high solar irradiance and ambient temperatures are the norm, two main factors degrade a panel’s output.

1. The Temperature Coefficient Effect

For every degree Celsius a solar module operates above 25°C, its power output decreases by a specific percentage. This loss is known as the temperature coefficient. While a loss of 0.35% per degree may seem small, the cumulative effect is substantial.

Consider a standard solar panel operating in a 45°C environment. The panel’s surface temperature can easily reach 70°C or higher.

Temperature Difference: 70°C – 25°C = 45°C above STC.

Efficiency Loss: 45°C x 0.35% loss/°C = 15.75% reduction in power output.

This means a 550-watt panel effectively becomes a 463-watt panel during the hottest parts of the day, which directly impacts energy yield and the financial viability of a solar project.

2. Soiling and Abrasion

Sudan’s climate is characterized by frequent dust storms and airborne sand. This presents two problems:

-

Soiling: A layer of dust on the module’s surface blocks sunlight from reaching the solar cells, causing energy yield losses of up to 30% if not regularly cleaned.

-

Abrasion: Over time, windblown sand can cause microscopic scratches on the glass surface, permanently reducing its transparency and, therefore, its efficiency.

Mitigating these inevitable environmental challenges begins with selecting the right technology from the very first step of the solar module manufacturing process.

Evaluating Key Solar Module Technologies for Sudan

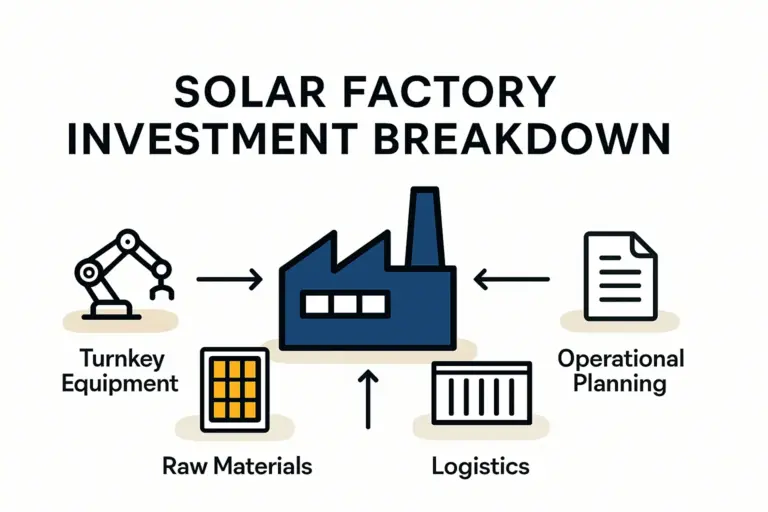

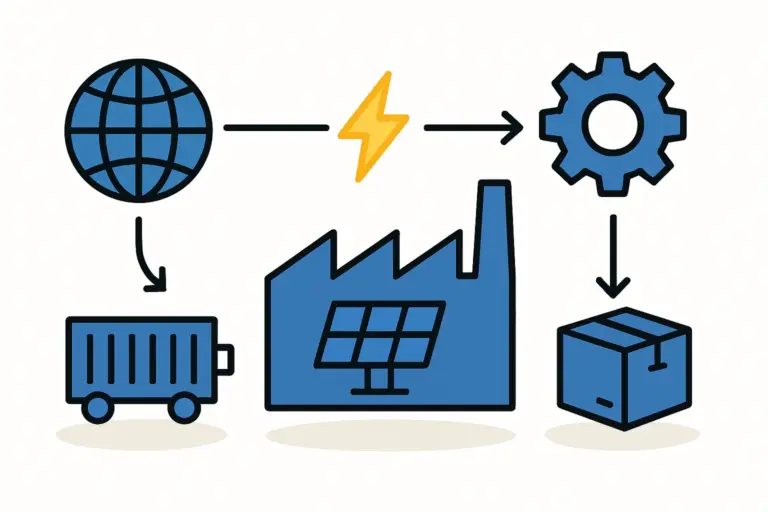

The choice of cell technology is one of the most critical decisions when establishing a solar factory. It dictates the performance characteristics of the final product and influences the required solar panel manufacturing machines. Let’s compare the most relevant options for the Sudanese market.

Standard Technology: PERC (Passivated Emitter and Rear Cell)

PERC has been the industry workhorse for years, valued for its cost-effectiveness and mature manufacturing process. It offers a significant efficiency improvement over older technologies.

How it Works: A passivation layer added to the rear of the solar cell helps reflect unabsorbed light back into the cell for a second chance at absorption, increasing overall efficiency.

Performance in Heat: Standard PERC modules typically have a temperature coefficient between -0.35% and -0.42% per °C. While reliable, they are still susceptible to the significant power losses discussed earlier when faced with extreme heat.

Best Suited For: Markets with moderate climates or where the initial cost is the primary decision driver. For Sudan, it represents a baseline but not an optimized solution.

Advanced Technology: TOPCon (Tunnel Oxide Passivated Contact)

TOPCon is the logical successor to PERC, offering higher efficiency and, crucially, better performance at elevated temperatures.

How it Works: TOPCon adds an ultra-thin tunnel oxide layer and a layer of highly doped polysilicon to the cell. This structure significantly reduces recombination losses, where charge carriers are lost before they can contribute to the electric current.

Performance in Heat: TOPCon modules boast a superior temperature coefficient, typically around -0.30% per °C. This improvement directly translates to higher energy yield in hot climates. Revisiting our 45°C example, the power loss with TOPCon would be closer to 13.5%—a meaningful improvement over PERC.

Best Suited For: Discerning markets where long-term energy yield and performance are prioritized. For a new manufacturer in Sudan, producing TOPCon modules creates an immediate competitive advantage over imported standard panels.

Specialized Solution: DESERT+ Technology

Some manufacturers offer modules specifically engineered for desert environments. This isn’t a distinct cell technology like PERC or TOPCon but rather an enhanced package of materials and design features.

How it Works: ‘Desert’ modules typically use high-performance cells (often TOPCon or HJT) combined with specialized encapsulation materials, more durable backsheets (or a glass-glass structure), and frames built to withstand high thermal expansion. They often feature anti-soiling coatings on the glass to repel dust and reduce the need for frequent cleaning.

Performance in Heat: Their primary benefit is a combination of a low temperature coefficient with exceptional material stability. These modules are designed to resist degradation from high UV radiation and wide temperature swings, ensuring a longer operational lifespan.

Best Suited For: Large-scale utility projects and premium commercial installations in the harshest desert regions. A factory planning a turnkey solar manufacturing line could strategically position itself as a provider of such high-performance, locally-adapted modules.

Based on experience from J.v.G. Technology GmbH turnkey projects, the decision between PERC and TOPCon is often a matter of balancing initial investment against long-term market positioning. For a market like Sudan, launching with TOPCon technology offers a more future-proof and competitive product.

The Business Case for High-Performance Modules

Choosing a technology with a better temperature coefficient isn’t just an engineering preference; it’s a strategic business decision.

-

Higher Annual Energy Yield: A module that loses less power during the day’s hottest hours will generate more kilowatt-hours over the course of a year. This improves the Levelized Cost of Energy (LCOE) for the end customer, making your product more attractive.

-

Stronger Market Reputation: Selling modules that perform exceptionally well in the local climate builds a powerful brand reputation. Customers will trust a local manufacturer who understands and engineers for local conditions.

-

Increased Project Bankability: For large-scale solar farms, investors and lenders look closely at energy yield predictions. Using high-performance modules with certified low temperature coefficients can make projects more financially viable and easier to fund.

-

Durability and Lower Warranty Claims: Modules designed for harsh environments, with robust materials and better heat dissipation, are less likely to suffer from premature degradation. This reduces the manufacturer’s long-term warranty risk.

Frequently Asked Questions (FAQ)

What is the most important specification when choosing a panel for a hot climate?

The temperature coefficient of power (Pmax) is the most critical factor. Look for values closer to -0.30%/°C or lower. Following that, consider the quality of materials (UV-resistant backsheet, durable frame) and any certifications for harsh environments (e.g., sand/dust resistance tests).

Is TOPCon technology much more expensive to manufacture than PERC?

While TOPCon requires additional machinery and process steps, the cost difference has narrowed significantly. The higher capital expenditure is often justified by the final product’s superior efficiency and performance, which can command a premium price and deliver greater value to the end user.

How effective are anti-soiling coatings?

They are highly effective. By creating a super-hydrophilic or hydrophobic surface, they help rainwater wash away dust more efficiently or prevent dust from adhering in the first place. This can reduce cleaning frequency and maintain a higher average energy yield, especially in dusty regions.

Can a new factory start with PERC and upgrade to TOPCon later?

Yes, this is a common upgrade path. Many PERC production lines can be retrofitted to produce TOPCon modules. However, planning for this upgrade from the beginning is essential to ensure the factory layout and initial machine selection can accommodate future additions. The pvknowhow.com e-course provides structured guidance on planning for such future-proofing.

Conclusion: Matching Technology to Market for Sustainable Success

For an entrepreneur entering the solar manufacturing space in Sudan, success depends on producing a product that is not just assembled locally, but is engineered for local conditions. While standard PERC modules offer a viable entry point, the clear technical and business advantages of TOPCon technology make it a superior choice for a market defined by intense heat and sun.

By prioritizing a lower temperature coefficient, durable materials, and technologies that combat soiling, a new manufacturer can deliver a product that consistently outperforms generic imports. This builds a foundation of trust, ensures long-term customer satisfaction, and establishes a strong, sustainable business in a rapidly growing energy market.