When considering a new solar module factory, an investor’s focus often turns to machinery, financing, and site selection. In a market like South Sudan, however, the most critical long-term investment is not the hardware but the people who will run it. The vision of a bustling production floor in Juba contributing to the nation’s energy independence hinges on a fundamental question: Who will operate, maintain, and lead this facility?

Building a high-performing technical team in a region with a developing industrial base presents unique challenges. Yet it also offers an extraordinary opportunity to cultivate local talent and create sustainable economic value. This article outlines a practical, three-pillar framework for developing a skilled local workforce for a solar module factory in South Sudan—transforming a potential obstacle into a strategic advantage.

Understanding the Human Capital Landscape in South Sudan

A successful workforce strategy must be grounded in the local reality. While international headlines may focus on the country’s challenges, a deeper analysis reveals a landscape of significant potential.

According to research from institutions like the African Development Bank, South Sudan has one of the youngest populations in the world, with over 70% of its citizens under 30. This demographic represents a vast, untapped reservoir of talent.

However, data also indicates that access to specialized Technical and Vocational Education and Training (TVET) has not kept pace with population growth, creating a gap between general education and the skills required for modern manufacturing.

This environment calls for a strategy that looks beyond formal qualifications to focus on identifying aptitude and building skills from the ground up. The factory’s success will depend not on finding ready-made experts, but on the commitment to creating them.

A Three-Pillar Framework for Workforce Development

A robust workforce plan can be structured around three core activities: strategic recruitment, a hybrid training model, and long-term retention and growth. This systematic approach ensures that every stage, from hiring the first employee to promoting a future factory manager, is carefully managed.

Pillar 1: Strategic Recruitment – Beyond Traditional Job Postings

In a market where relevant industrial experience is scarce, conventional recruitment methods that filter candidates by work history are often ineffective. A more strategic approach is required.

- Partnerships with Educational Institutions: Partner with local universities and TVET centers. While they may not offer solar-specific programs, they are the primary source of individuals with foundational knowledge in electrical, mechanical, or general engineering.

- Aptitude-Based Assessment: Prioritize aptitude over experience. A simple, hands-on test assessing mechanical reasoning, attention to detail, and problem-solving can reveal high-potential candidates who lack a formal CV. The crucial factor is a candidate’s capacity and willingness to learn.

- Community Engagement: Work with local community leaders to identify individuals known for their reliability, work ethic, and technical curiosity. This grassroots approach can uncover hidden talent that a newspaper advertisement would never reach.

Defining the number of employees and their roles is fundamental to budgeting the full solar factory investment requirements.

Pillar 2: The Hybrid Training Model – Blending Global Expertise with Local Talent

The most effective way to bridge the skills gap is through a structured knowledge transfer program. This involves bringing in a small number of external experts whose primary mission is not to run the factory, but to train their local successors.

The “Train the Trainer” model is a cornerstone of successful industrial projects in emerging markets. Experience from J.v.G. Technology GmbH’s turnkey projects shows this approach builds sustainable local capacity and is far more cost-effective than long-term reliance on expatriate staff.

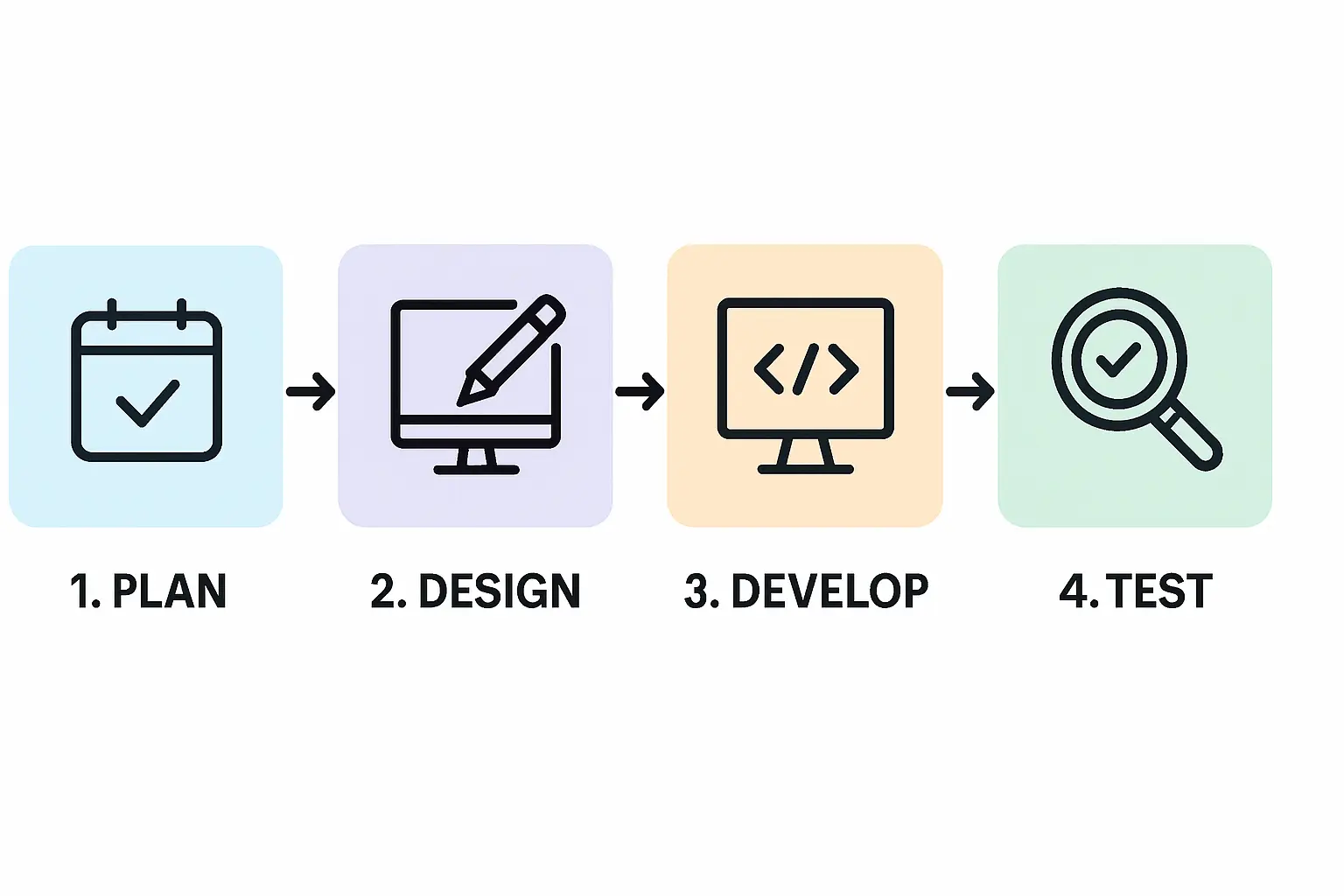

The training program should be phased:

- Classroom Foundations: A dedicated period to learn the fundamentals of the solar module manufacturing process, including workplace safety, quality control standards, and the function of each machine.

- Supervised On-the-Job Training: Trainees work on the production line under the close supervision of expert trainers. This phase focuses on mastering standard operating procedures for all equipment, from the stringer to the final laminator.

- Advanced Skills Development: Once basic operations are mastered, the focus shifts to troubleshooting, preventive maintenance, and process optimization. This is where the core group of local team leaders is identified and developed.

Pillar 3: Retention and Growth – Building Careers, Not Just Jobs

After investing significantly in training, retaining skilled employees becomes the highest priority. High staff turnover can cripple a new factory, leading to production delays and quality issues. A strong retention strategy is built on creating long-term career opportunities.

- Clear Career Paths: Define a clear progression from entry-level Operator to Senior Operator, Team Leader, and eventually Shift Supervisor. This structure provides employees with a visible future in the company, encouraging long-term commitment.

- Competitive Compensation: Compensation must be benchmarked against other industrial employers in the region to ensure the factory is seen as a premier place of employment.

- A Culture of Ownership: Empower local team leaders with genuine responsibility. When employees feel a sense of ownership over their work and pride in contributing to a nationally significant project, their loyalty and performance increase.

A project in West Africa offers a compelling example. The first local technician hired and trained by an expatriate engineer at a new module factory is now the Production Manager, overseeing all manufacturing operations and training new staff himself. This is the ultimate goal of a sustainable workforce development plan.

Business-Relevant Metrics: Planning Your Workforce

For initial planning, a semi-automated 20–50 MW solar module factory typically requires a direct workforce of 25 to 35 people to operate a single shift.

A typical breakdown of roles includes:

- Production Operators: 15–20

- Quality Control Technicians: 2–3

- Maintenance Technicians: 2–3

- Warehouse & Logistics Staff: 3–4

- Supervisory/Management Staff: 2–3

An investor should budget for an intensive 4–6 month training period before the production line can run consistently at its target capacity under full local supervision. These staffing and training plans are integral to a turnkey solar factory setup.

Frequently Asked Questions (FAQ)

Is it necessary to hire expatriate engineers for the long term?

No, the objective is knowledge transfer. Expatriate experts are essential during the initial 12–24 months for installation, commissioning, and intensive training. The goal is to make their presence temporary by building a self-sufficient local team.

What level of education is required for production operators?

While a secondary school education is beneficial, the most important attributes are a strong work ethic, attention to detail, and the ability to follow systematic processes. For these roles, aptitude and trainability are more critical than formal academic credentials.

Can we find people with basic electrical or mechanical skills locally?

Yes. In many developing economies, a strong informal sector gives individuals practical, hands-on skills in mechanics and electronics. A strategic recruitment process can identify these individuals and provide the specialized training needed for PV manufacturing.

How important is English proficiency for the factory staff?

English proficiency is crucial for the core group of team leaders, maintenance technicians, and managers who must understand technical machine manuals and communicate with international trainers or suppliers. For general production operators, training can be delivered effectively in the local language by trained local team leaders.

Conclusion: Your People Are Your Most Critical Asset

Launching a solar module factory in South Sudan is an ambitious and transformative endeavor. While securing the right technology and capital is vital, the venture’s long-term success will be determined by the quality and commitment of its local workforce.

By implementing a strategic framework for recruitment, training, and retention, an investor can systematically build a skilled and motivated team from the ground up. This approach not only mitigates operational risk but also creates a powerful engine for local economic development. A well-planned human capital strategy is the ultimate guarantee of a factory that produces high-quality solar modules while building a lasting legacy of technical expertise and opportunity. Understanding all the steps, including the final solar panel certification process, is key to a holistic plan.