Spain as a Strategic Hub for Solar Module Manufacturing: A Gateway to Europe and North Africa

Entrepreneurs looking to manufacture solar modules face a critical decision: where to establish their production facility. The choice is typically a trade-off. A low-cost region may reduce initial expenses but can create logistical hurdles and challenges in accessing premium markets. On the other hand, a base in a highly developed market might offer quality and stability at the cost of access to emerging, high-growth regions.

This analysis considers a third option that balances these considerations: establishing a manufacturing hub in Spain. Its unique position offers a strategic gateway to two distinct, high-potential markets—the established European Union and the rapidly growing economies of North Africa. For investors, this dual-market access makes for a compelling business case.

Why Spain Offers a Unique Geographic and Economic Advantage

Spain’s strategic value stems from its geography. Positioned at the southwestern edge of Europe and just 14 kilometers from the African continent at the Strait of Gibraltar, the country serves as a natural bridge between two worlds. This geography is also a significant logistical asset.

Major deep-water ports like Algeciras, Valencia, and Barcelona are among the busiest in the Mediterranean, providing world-class infrastructure for importing raw materials and exporting finished solar modules. A manufacturer based in Spain can efficiently manage supply chains from Asia while serving customers in Berlin or Casablanca with significantly reduced shipping times and costs compared to an Asian factory.

This location moves beyond the ‘either/or’ dilemma of market focus, allowing a single facility to pursue a diversified, dual-market export strategy.

Accessing the European Union: A Market of Stability and High Standards

Manufacturing in Spain provides direct and unconditional access to the European Union’s Single Market—a bloc of 27 countries with over 450 million consumers. For a solar module producer, this offers several distinct advantages.

The Benefits of ‘Made in Europe’

-

Frictionless Trade: Products manufactured in Spain can be sold anywhere in the EU without tariffs, customs checks, or complex import procedures. This seamless access is a significant operational and financial advantage.

-

Regulatory Alignment: The EU is moving to bolster its domestic manufacturing capabilities. Initiatives like the Net-Zero Industry Act, which aims for European manufacturing to meet 40% of the EU’s annual clean-tech needs by 2030, create a supportive policy environment for local producers.

-

Brand Credibility: A ‘Made in Spain’ label signifies adherence to stringent European quality and environmental standards. For customers both inside and outside the EU, this serves as a powerful mark of trust and reliability. Meeting EU standards and certifications is more than a requirement; it’s a competitive differentiator, particularly when exporting to African markets where European quality is highly valued.

Experience from J.v.G. turnkey projects shows that establishing a factory in an EU country requires meticulous planning around compliance, but in return, it offers unparalleled market access and long-term stability.

Tapping into North Africa’s Growing Solar Demand

While the EU offers stability, North Africa represents immense growth potential. Countries like Morocco, Algeria, and Egypt are experiencing rising energy demands and have ambitious renewable energy targets, driven by abundant solar irradiation.

A Spanish manufacturing base is uniquely positioned to serve this burgeoning market.

-

Logistical Proximity: Shipping modules from a Spanish port to North Africa can take a matter of days, not weeks. This speed reduces inventory holding costs for buyers and allows for a more responsive supply chain.

-

Reduced Costs: Lower transportation distances directly translate into lower freight costs per module, making Spanish-made panels more competitive on landing cost compared to those shipped from East Asia.

-

Cultural and Commercial Ties: Spain shares deep historical and commercial relationships with the Maghreb region, which can facilitate smoother business negotiations and partnerships.

This proximity allows a manufacturer to act as a regional supplier, building stronger relationships and a more resilient business than a distant competitor could.

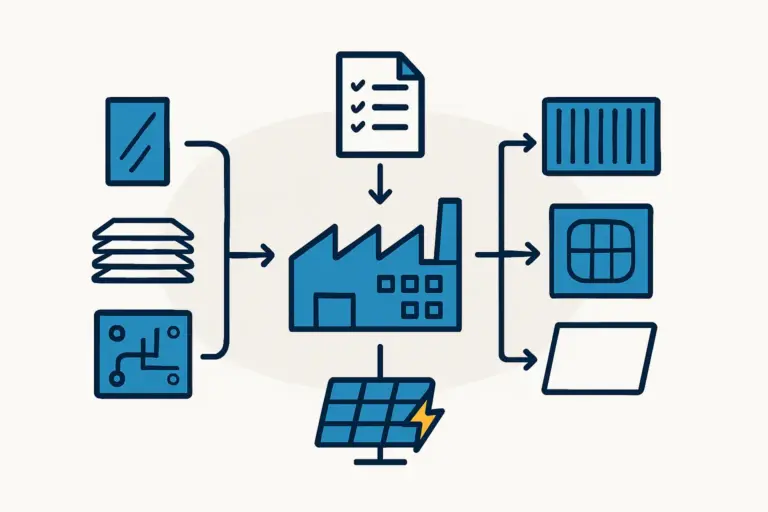

The Operational Foundation: What Manufacturing in Spain Entails

Establishing a production facility in Spain builds on a foundation of quality and technical expertise. As a European leader in renewable energy, ranking second in installed solar capacity, the country has a skilled workforce familiar with advanced manufacturing processes.

While labor and operational costs are higher than in some emerging economies, this expense is an investment in quality, consistency, and reliability. Setting up a solar module factory in Spain means leveraging this industrial ecosystem.

Careful planning of the initial investment is crucial, as is establishing robust supply chains for sourcing raw materials through Spain’s excellent port infrastructure. The outcome is a high-quality product manufactured in a stable, predictable economic environment, capable of meeting the most stringent global requirements.

Frequently Asked Questions (FAQ)

What are the primary advantages of manufacturing in Spain over a lower-cost country?

The key advantages are strategic, not purely cost-based. They include tariff-free access to the entire EU market, the high credibility of a ‘Made in Europe’ product, superior quality control, and significantly lower logistics costs and delivery times when exporting to both European and North African markets.

Is it difficult to navigate EU regulations for a new manufacturer?

EU regulations are comprehensive and require expert guidance. However, the framework is standardized across all 27 member states. Once compliance is achieved, it unlocks the entire single market, streamlining trade and eliminating the need to meet different national standards.

How does a Spanish base help with sourcing components?

A Spanish location offers sourcing flexibility. While bulk materials like solar cells may still be imported from Asia, Spain’s ports make this process efficient. Additionally, proximity to a growing number of European suppliers for other key components—such as high-quality solar glass, aluminum frames, and junction boxes—can reduce supply chain risks.

What is a realistic timeline for setting up a solar factory in Spain?

A typical timeline for a greenfield project, from initial planning to full commissioning, is between 12 and 18 months. This can vary based on the complexity of the facility, the permitting process in the specific autonomous community, and construction schedules.

Next Steps in Your Strategic Planning

Choosing Spain as a potential manufacturing base is not just about geography; it’s about adopting a specific market strategy. This approach prioritizes quality, stability, and dual-market access over simply minimizing initial labor costs.

For entrepreneurs and investors targeting the premium European market while positioning themselves to capture growth in North Africa, this strategy merits serious consideration. A detailed feasibility study and comprehensive business plan are the critical next steps to validate this approach and build your roadmap from concept to a fully operational facility.