For a post-conflict nation, the path to recovery is paved with foundational investments. While immediate needs like housing and healthcare are paramount, the energy needed to power them is the invisible bedrock of all reconstruction.

For Syria, a country with immense solar potential but a severely damaged power grid, domestic solar panel manufacturing presents a strategic opportunity. It’s a chance to rebuild not just infrastructure, but national resilience and economic independence. Establishing a local factory goes beyond simply importing technology; it builds a self-sustaining ecosystem that generates power, jobs, and long-term stability.

Understanding Syria’s Critical Energy Deficit

The case for solar energy begins with the scale of Syria’s current energy crisis. Before 2011, the national power grid had an installed capacity of approximately 9.5 gigawatts (GW). Today, due to extensive damage, its operational capacity has fallen to around 2 GW—a drop of over 70%.

This collapse has created a severe energy deficit with profound consequences:

- Critical Services at Risk: Hospitals, water treatment plants, and communication networks are often forced to rely on expensive and unreliable diesel generators.

- Economic Stagnation: Businesses cannot operate consistently, which hinders economic recovery and job creation.

- Humanitarian Impact: A lack of reliable electricity affects every aspect of daily life, from food preservation to education.

Yet, Syria is blessed with one of the world’s most favorable climates for solar power, receiving 2,000 to 2,600 kilowatt-hours of solar irradiation per square meter annually. This untapped natural resource offers a direct and sustainable path out of the country’s energy crisis.

Why Domestic Manufacturing is a Strategic Solution

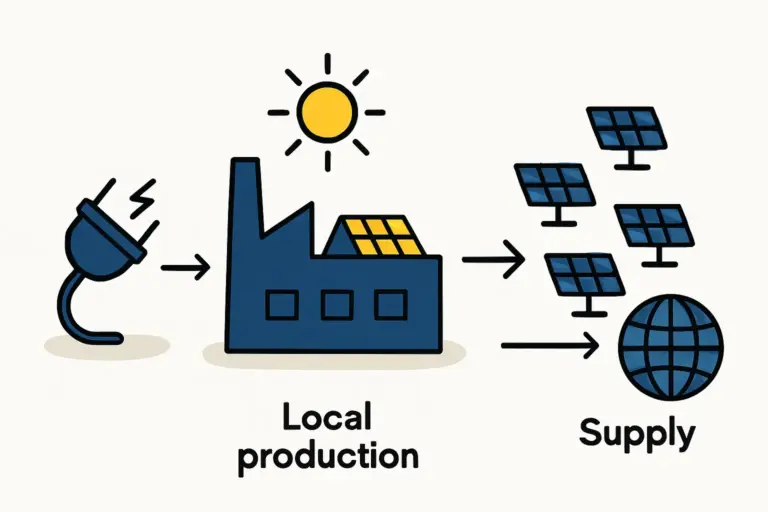

While importing solar panels offers a short-term fix, establishing domestic manufacturing capabilities provides far greater long-term benefits for a nation in reconstruction. It is an investment in industrial capacity, technical expertise, and a self-sufficient future.

Driving Economic Recovery and Skilled Employment

A solar panel factory is more than a building with machines; it’s a hub of economic activity. Such a facility would create direct employment for skilled professionals, from engineers and technicians to quality control specialists and line operators. This is a critical step toward rebuilding a nation’s human capital and providing meaningful livelihoods.

It also stimulates a secondary economy of suppliers, logistics providers, and installation companies. For entrepreneurs and investors considering this sector, understanding how to start a small solar factory is the first step in contributing to this industrial revival.

Building Energy Independence and Resilience

Relying on imports leaves a country vulnerable to global supply chain disruptions, currency fluctuations, and geopolitical instability. A domestic manufacturing base ensures a consistent, reliable supply of solar panels—essential for large-scale, long-term reconstruction.

By producing modules locally, the country can systematically deploy decentralized solar power to critical infrastructure. This approach ensures that hospitals, schools, and water pumps can function independently of a fragile central grid, building a more resilient and secure society. This is a core advantage that cannot be achieved through imports alone.

Ensuring Quality and Adaptability for Local Conditions

Solar panels are not a one-size-fits-all product. The Middle Eastern climate, with its high temperatures and dust, places specific demands on module technology. A local factory can design and produce panels optimized for these conditions, ensuring better performance, longevity, and return on investment.

Local quality control also means panels can be manufactured to meet the specific standards required by international aid organizations or government reconstruction contracts, building trust and facilitating further investment.

Practical Considerations for Establishing a Solar Factory

Embarking on such a project in a post-conflict environment requires careful planning and a clear-eyed view of the investment landscape. Experience from turnkey projects in emerging markets, like those implemented by J.v.G. Technology GmbH, shows that a phased, structured approach is critical for success.

Key considerations include:

- Initial Investment: The cost of the solar panel production line is a primary factor. This can be scaled from a smaller, semi-automated line to a larger, fully automated facility, depending on the target capacity and available capital.

- Logistics and Supply Chain: While some raw materials like silicon cells will likely be imported, a plan for sourcing other components such as glass, aluminum frames, and junction boxes is essential.

- Workforce Training: A comprehensive training program is vital to equip the local workforce with the technical skills needed to operate and maintain the production machinery.

For investors and organizations, a turnkey solar factory solution offers a streamlined path from business planning and equipment procurement to commissioning and staff training, mitigating many inherent project risks.

Frequently Asked Questions (FAQ)

What is a typical starting capacity for a solar factory in this context?

A small to medium-sized factory with an annual capacity of 20-50 MW (megawatts) is a practical starting point. This size is large enough to make a significant impact on local energy needs while keeping the initial investment manageable.

How long does it take to set up a production line?

With a clear plan and an experienced technical partner, a solar module production line can be operational in under 12 months, from project confirmation to the first panel rolling off the line.

Are all raw materials for solar panels available in Syria?

While Syria may have resources for components like glass and aluminum frames, specialized materials like photovoltaic cells are typically imported from established global suppliers. The local factory’s primary role is the high-value assembly, lamination, and testing.

What kind of skills are required for the workforce?

The workforce needs a mix of skills, including university-educated engineers for process management and quality control, vocationally trained technicians for machine operation and maintenance, and a general labor force for assembly and logistics. All personnel would receive specialized training on the production equipment.

A Strategic Investment in the Future

Local solar panel manufacturing in Syria is not just an energy project; it is a nation-building initiative. It addresses the immediate need for power and lays the groundwork for long-term economic stability, technological advancement, and national self-reliance. By transforming abundant sunlight into electricity, jobs, and opportunity, it represents a powerful and strategic investment in a brighter, more resilient future.