Establishing a solar module factory in a region undergoing reconstruction like Syria presents both unique challenges and significant opportunities.

While securing financing and equipment are critical milestones, the venture’s long-term success hinges on an often-underestimated factor: developing a skilled local workforce. An entrepreneur will rightly ask, ‘How can we build a team of proficient technicians and engineers in a market where specialized solar manufacturing experience is scarce?’

The answer lies not in searching for ready-made experts, but in a systematic approach to cultivating talent. Research into post-conflict industrialization consistently shows that investing in human capital yields the highest returns and creates a sustainable operational advantage. This article outlines a practical framework for recruiting, training, and developing a capable workforce for a solar module assembly line in the Syrian context.

Understanding the Core Roles in a Solar Module Factory

A semi-automated solar module production line, typical for a 20-50 MW capacity, doesn’t require a large team of PhD-level scientists. It relies instead on a well-organized group of individuals with distinct, well-defined roles. A typical small-scale factory can be operated efficiently with a team of 25 to 30 employees per shift.

Machine Operators

Operators form the backbone of the production line. Their primary responsibility is to operate specific machinery, such as the cell stringer, laminator, or framing station. An ideal candidate has good hand-eye coordination, a strong attention to detail, and the ability to follow standardized operating procedures meticulously.

Maintenance Technicians

No production line runs without occasional downtime. Maintenance technicians are essential for troubleshooting, repairing, and conducting preventive maintenance on the machinery. A background in mechanics, electronics, or industrial maintenance is a major advantage for this role. Their work directly impacts the factory’s uptime and overall output.

Quality Control (QC) Inspectors

QC inspectors are the guardians of product quality. They perform visual inspections, operate testing equipment like sun simulators and EL testers, and ensure that every module meets stringent international standards. This role requires a methodical and uncompromising approach to quality assurance—a non-negotiable part of achieving the necessary solar panel certification standards.

Production Engineers and Supervisors

This leadership group oversees the entire production process. They manage workflows, train operators, analyze production data to improve efficiency, and ensure safety protocols are followed. An engineering degree or significant experience in a manufacturing environment is typically required for these positions.

Addressing the Local Skill Gap: A Strategic Approach

In a market like Syria, it is unrealistic to expect a large pool of candidates with direct experience in photovoltaic manufacturing. This apparent disadvantage, however, can become a strategic opportunity. By implementing a structured development program, a company can build a highly loyal and capable team from the ground up, shaping the workforce’s culture and skill set to match its specific operational needs.

The key is to shift the recruitment focus from past experience to future potential. The most successful turnkey projects in emerging markets have prioritized candidates with strong foundational aptitudes—such as problem-solving skills, technical curiosity, and a disciplined work ethic—over specific industry knowledge.

A Three-Phase Framework for Workforce Development

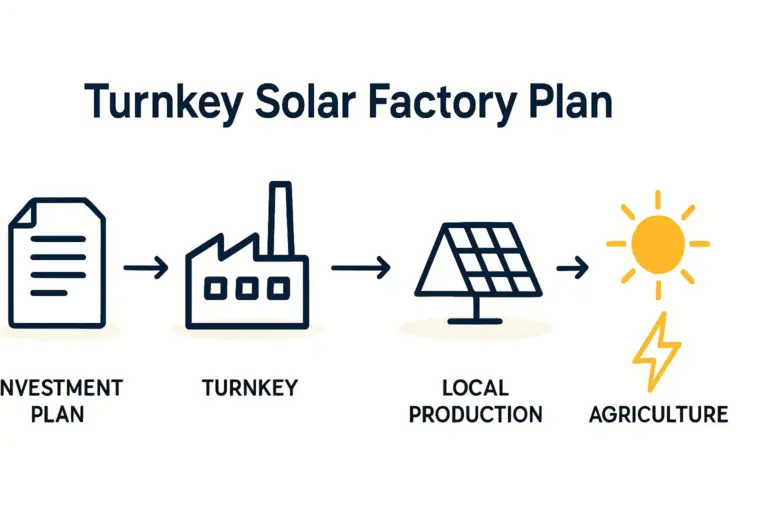

A systematic approach ensures that the new team is not just hired but fully prepared to excel from day one. This process is a crucial element of the overall turnkey solar factory setup and should be planned with the same diligence as equipment procurement.

Phase 1: Strategic Recruitment

The goal is to identify individuals with the right aptitude for a manufacturing environment.

-

Sourcing Channels: Look beyond general job boards. Engage directly with local technical and vocational training institutes, university engineering departments, and industries with transferable skills, such as electronics assembly, automotive repair, or general manufacturing.

-

Screening Criteria: Focus on assessing problem-solving abilities, attention to detail, and a candidate’s capacity to learn. Practical tests can be more insightful than interviews alone. For example, a simple hands-on assembly task can reveal a great deal about a candidate’s dexterity and ability to follow instructions.

Phase 2: Comprehensive In-House Training

This is the most critical phase and should happen before the production line is officially commissioned. A well-designed program blends theory with extensive hands-on practice.

-

Theoretical Foundation: Begin with classroom sessions covering the fundamentals of photovoltaic technology, material handling, safety protocols, and the principles of quality management.

-

Hands-On Machine Training: Each operator must receive supervised, practical training on the specific solar panel manufacturing machines they will be using. This training is often provided by the equipment supplier’s engineers as part of the installation and commissioning package. Based on experience from J.v.G. turnkey projects, this direct knowledge transfer from the machine experts is invaluable.

- Process Simulation: Before using valuable raw materials, the team should run practice cycles on the entire line. This helps them understand the production flow, identify potential bottlenecks, and build confidence in their roles.

Phase 3: Partnering with Local Institutions

For long-term sustainability, establishing a connection with the local educational ecosystem is a powerful strategy.

-

Curriculum Collaboration: Work with local vocational schools to develop a curriculum that aligns with the factory’s needs. This could involve offering internships, providing guest lecturers, or even donating older equipment for training purposes.

-

Creating a Talent Pipeline: Such a partnership ensures a continuous supply of pre-qualified candidates for future expansion or staff turnover. It also positions the company as a key contributor to local industrial development, enhancing its reputation and social license to operate.

The Business Case for Investing in Training

A thorough training program is not a cost center; it is a high-return investment. A well-trained workforce contributes directly to the bottom line by:

-

Reducing Material Waste: Skilled operators make fewer errors, significantly lowering the scrap rate of expensive materials like solar cells and EVA foil.

-

Improving Product Quality and Yield: Consistent adherence to quality standards results in a higher yield of certifiable, top-grade modules.

-

Increasing Operational Uptime: Well-trained technicians can diagnose and fix issues faster, maximizing the machinery’s production hours.

-

Enhancing Workplace Safety: A deep understanding of safety protocols reduces the risk of accidents, protecting both employees and company assets.

Frequently Asked Questions (FAQ)

How many employees are needed for a small-scale (20-50 MW) factory?

A typical semi-automated line of this capacity can be run by a team of approximately 25-30 people per shift, including operators, technicians, QC staff, and supervisors.

What qualifications are most important for the factory manager?

The factory manager should have a strong background in production management or industrial engineering. While solar-specific experience is an asset, proven leadership in any sophisticated manufacturing environment is the most critical qualification.

How long does it take to train a new team from scratch?

A comprehensive training program, from recruitment to operational readiness, typically takes three to four months. This timeline should be integrated into the overall project plan.

Is prior experience in the solar industry necessary for machine operators?

No. For operator roles, it is more effective to hire for aptitude, discipline, and trainability. The necessary skills can be taught much more easily than a foundational work ethic.

Conclusion: Building More Than Just Solar Panels

For an entrepreneur entering the solar manufacturing sector in Syria, the workforce is the most critical asset. Building a solar module factory is also an opportunity to build local technical capacity, create stable employment, and contribute directly to the country’s energy independence and reconstruction.

By adopting a structured approach to recruitment and investing in training, a new venture can overcome the initial skill gap and establish a foundation for long-term profitability and sustainable growth. This investment in people is what ultimately transforms a collection of advanced machinery into a thriving, high-quality manufacturing operation.

For business professionals seeking a structured path, the pvknowhow.com e-course provides detailed modules on human resource planning and factory setup.