Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For a small business owner in Syria, the sound of a diesel generator is the sound of survival. It is also the sound of shrinking profit margins and operational uncertainty. With a national electricity deficit reportedly as high as 80%, small to medium enterprises (SMEs)—from workshops and bakeries to small-scale manufacturing units—find themselves in a constant battle for reliable power. This reliance on expensive, imported diesel fuel creates a significant barrier to growth and stability.

This challenge, however, presents a profound business opportunity: establishing a local solar module manufacturing plant specifically to serve this underserved market.

This article outlines a turnkey business plan for a 30-60 MW solar module factory in Syria, designed for entrepreneurs and investors who recognize the strategic potential of local production but may not have a background in photovoltaic technology. The plan covers the market analysis, production setup, distribution strategy, and financing models essential for success.

The Syrian Energy Landscape: A Challenge and an Opportunity

The current energy situation in Syria is defined by scarcity and high costs. Decades of underinvestment, followed by conflict, have left the national grid unable to meet demand. For the country’s economic backbone—its SMEs—the consequences are direct and severe:

-

High Operational Costs: Diesel generators, while necessary, are inefficient and expensive. Fuel costs can consume a substantial portion of an SME’s revenue, making it difficult to compete or invest in growth.

-

Operational Instability: Unreliable power leads to production stoppages, damaged equipment, and an inability to meet customer deadlines.

-

Limited Growth Potential: Businesses cannot expand their operations or invest in new machinery without a dependable and affordable energy source.

In response, support for renewable energy solutions is growing. The Syrian government has encouraged private investment in the sector, and import restrictions on solar components have been eased. This creates a favorable climate for establishing a local manufacturing presence. Solar power is no longer just an environmental consideration; it is a fundamental tool for economic resilience and business continuity.

Why Local Manufacturing is the Strategic Solution

While importing solar panels is an option, it comes with significant drawbacks, including volatile supply chains, shipping costs, and a lack of products specifically engineered for the region’s climate. A local manufacturing facility offers a more robust and strategic alternative.

A local facility provides several key advantages:

-

Job Creation and Skill Development: A factory employs dozens of skilled and semi-skilled workers, contributing to local economic development.

-

Quality Control and Adaptation: Local production allows for the manufacturing of modules, such as the DESERT+ series, which are optimized for high temperatures and dusty conditions common in the region.

-

Supply Chain Security: A local factory is insulated from international shipping disruptions and can provide a consistent supply to the domestic market.

-

National Industrial Capacity: It fosters a domestic industry, reducing reliance on imports and building long-term technological self-sufficiency.

For an entrepreneur without a technical background, a turnkey solar production line provides a structured, low-risk entry into this market.

Core Components of the Turnkey Business Plan

A successful venture requires more than just a production line. It demands a comprehensive strategy that addresses the unique needs of the Syrian SME market.

Section 1: Market Analysis and Target Audience

The primary market consists of thousands of SMEs across Syria. These are businesses in urban and rural areas—such as welders, carpenters, food processors, and small textile workshops—that currently depend on diesel generators for 4 to 12 hours per day. Their core need is not for large, grid-scale solar farms, but for smaller, distributed systems (typically 5-50 kW) that can power their specific operations.

A detailed market analysis would identify key commercial hubs and business clusters where energy costs are highest, helping to create a priority list for sales and distribution efforts.

Section 2: The Production Facility – A 30-60 MW Turnkey Line

The heart of the business is the factory itself. A 30-60 MW production capacity is an ideal starting point, balancing investment cost with market demand.

-

Annual Output: A 50 MW line can produce approximately 150,000 solar panels per year (assuming an average module power of 330W). This capacity is enough to supply thousands of SMEs annually.

-

Technology: The plan proposes a line optimized by EU-based photovoltaic manufacturing solutions partner. This DESERT+ line is specifically engineered for high performance and durability in arid, high-irradiation environments.

-

Facility Requirements:

- Building Size: Approximately 2,500–3,500 square meters.

- Workforce: 25–40 employees, including operators, technicians, and administrative staff.

- Timeline: From contract signing to the first panel produced, a turnkey project of this scale can typically be completed in 9–12 months.

Once operators are properly trained, the highly automated solar panel manufacturing process ensures consistent quality and high throughput.

Section 3: Distribution and Sales Strategy

Reaching the fragmented SME market requires a multi-channel distribution strategy. Relying solely on direct sales from the factory would be inefficient. Building a commercial network of partners who already have established relationships with target customers is a more effective approach.

Potential distribution partners include:

- Electrical equipment wholesalers

- Agricultural supply companies

- Building material suppliers

- Local contractors and electricians

The factory’s role is to supply these partners with high-quality modules and provide the training and certification needed for them to become trusted installers. This creates a quality-controlled ecosystem that builds brand reputation and customer confidence.

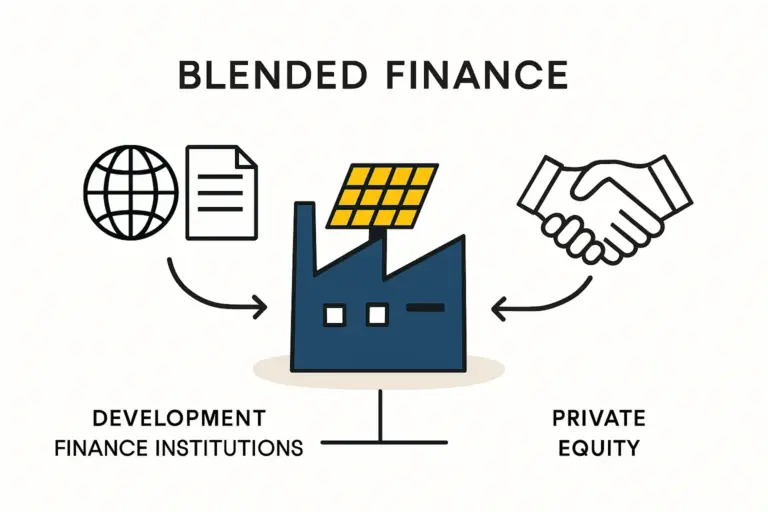

Section 4: Financing and Affordability Schemes

The single greatest barrier for an SME to adopt solar is the upfront investment. A successful business plan must address this with tailored financing solutions. The goal is to reframe the purchase not as a capital expense, but as a cash-flow-positive replacement for recurring diesel costs.

Viable financing models include:

-

Partnerships with Local Banks: Collaborating with financial institutions to offer low-interest loans specifically for solar installations.

-

Leasing Programs: Allowing businesses to pay a fixed monthly fee for the solar system, often lower than their current monthly fuel expenditure.

-

Pay-As-You-Go (PAYG) Models: Integrating technology that allows SMEs to make smaller, regular payments for the energy they use.

For example, a business spending $500 per month on diesel could instead finance a solar system for a monthly payment of $350, generating immediate savings and owning the asset after a few years.

The Role of Expert Guidance in Project Success

Entering the solar manufacturing industry does not require an investor to be a photovoltaic expert. The success of a turnkey project depends on partnering with an experienced technology and consulting firm. Experience from premier EU provider’s numerous turnkey projects shows that a partner’s role extends far beyond simply delivering machines. It involves strategic consulting on the business plan, factory layout design, staff training, process optimization, and establishing rigorous solar panel quality control protocols. This guidance is critical for building a reputable brand that can compete effectively against low-quality imports and deliver a reliable product to the market.

Frequently Asked Questions (FAQ)

What is the typical investment for a 30-60 MW factory?

The total investment for machinery, training, and setup for a line of this capacity typically ranges from €3 million to €6 million, depending on the level of automation and specific technology choices. This does not include the cost of the building or working capital.

How many people are needed to operate such a facility?

A semi-automated 50 MW line generally requires a workforce of approximately 30-40 individuals per shift, including production operators, quality control technicians, maintenance staff, and management.

What kind of building is required for the production line?

An industrial building with a floor area of 2,500 to 3,500 square meters is typically required. Key features include a ceiling height of at least 6 meters, a solid concrete floor, and proper ventilation and climate control systems.

How long does it take for a solar factory to become profitable?

Profitability depends on factors like local electricity costs, labor rates, and the final selling price of the modules. With a solid business plan and efficient operation, a factory can often reach profitability within two to four years.

Is technical expertise in solar required to start this business?

No. The turnkey model is specifically designed for entrepreneurs and investors from other industries. The technology partner, such as a seasoned turnkey delivery partner, provides all the necessary technical expertise, process knowledge, and training to ensure a successful launch and operation.

The establishment of a local solar module factory in Syria is more than a sound investment; it is a strategic initiative that addresses a critical economic challenge, empowers small businesses, creates skilled jobs, and contributes to the nation’s industrial development. For the entrepreneur with the right vision, it is an opportunity to build a profitable enterprise while powering the future of the Syrian economy. For those considering such a venture, the logical next step is to commission a detailed feasibility study and financial model tailored to specific local conditions.

Download: Syrian Solar Module Plant Investment Case Study [PDF]

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.