Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Picture one of the world’s largest industrial zones, spanning over 4,400 hectares, with the potential to house thousands of factories and employ tens of thousands of workers. Now, consider this economic engine operating at a fraction of its capacity—not from a lack of demand or skilled labor, but because of a fundamental constraint: unstable electricity.

This is the reality for the Aleppo Industrial City (Sheikh Najjar), a powerful symbol of Syria’s industrial potential that is currently hindered by chronic energy shortages.

This article proposes a strategic blueprint to address this core challenge: establishing a 50-100 MW turnkey solar module manufacturing plant within the industrial zone itself. This is not merely a proposal for another factory; it is a plan for an ‘enabling industry’—a foundational enterprise that can power the revival of hundreds of others.

The Core Challenge: Energy Deficits Stifling Economic Revival

To understand the opportunity, we must first grasp the main obstacle. Before the conflict, the Aleppo Industrial City was a thriving hub with over 2,000 operational factories. While hundreds of businesses have shown remarkable resilience by reopening, the unreliable national grid severely restricts their growth.

This forces entrepreneurs to rely on private diesel generators, a solution plagued by significant drawbacks:

-

High Operational Costs: Diesel fuel is expensive and subject to volatile pricing, eroding profit margins and making long-term financial planning nearly impossible.

-

Logistical Complexity: Securing and transporting fuel creates a constant logistical burden for factory managers.

-

Environmental Impact: Heavy reliance on diesel generation contributes to local air pollution and conflicts with global trends toward sustainable industrial practices.

The lack of stable, affordable power is the single greatest barrier to attracting new investment and restoring the industrial zone to its full potential.

A Strategic Solution: The ‘Enabling Industry’ Model

A local solar module factory offers a direct, sustainable solution. By producing photovoltaic (PV) modules within the industrial zone, the project creates a virtuous cycle. It becomes a catalyst for reconstruction, providing the very tool other businesses need to achieve energy independence.

This ‘enabling industry’ model offers several strategic advantages:

-

Energy Security: Factories can install their own solar power systems using locally made panels, ensuring a consistent power supply during daylight hours and reducing their reliance on the unstable grid and expensive diesel.

-

Cost Stability: After the initial investment, solar energy provides a predictable, low operational cost, insulating businesses from fuel price fluctuations.

-

Economic Multiplier Effect: The factory itself creates skilled jobs. More importantly, by providing stable power, it enables countless other factories to expand operations and hire more workers.

-

Attracting Investment: A reliable energy infrastructure is a critical prerequisite for attracting new domestic and international investment to the industrial zone.

A local PV plant would not just sell a product; it would sell the certainty and stability the entire industrial ecosystem needs to thrive.

Project Blueprint: Key Components for a 50-100 MW Turnkey Factory

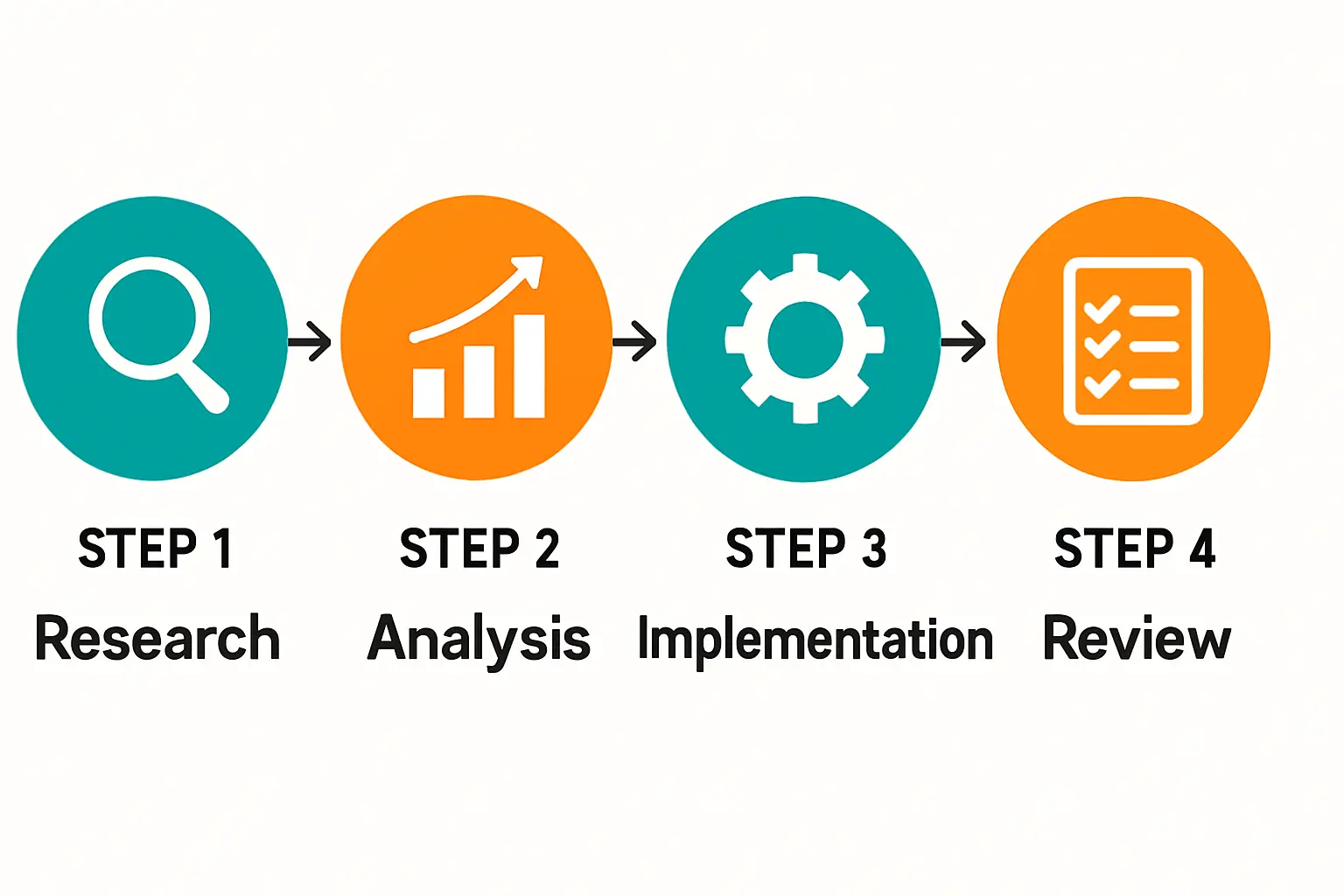

A project of this scale, particularly in a post-conflict environment, requires a meticulous, holistic approach. A turnkey solution, where a single expert partner manages the entire process from concept to operation, is the most effective model. This approach, drawing on experience from turnkey projects managed by firms like a specialized EU engineering partner, minimizes risk and accelerates the timeline for investors who may lack a background in PV manufacturing.

Financing and Partnership: The Public-Private Partnership (PPP) Model

For a project with such significant public benefit, a Public-Private Partnership (PPP) is an ideal financial and operational structure. This model leverages the strengths of both sectors:

-

Public Partner (e.g., Industrial City Administration): Can facilitate access to land, streamline permitting and licensing, and provide regulatory support. Their participation signals official backing and adds stability to the project.

-

Private Partner (e.g., a consortium of investors): Provides the capital investment, operational expertise, and commercial drive.

-

Technical Partner (e.g., premier EU provider): Delivers the specialized engineering knowledge for planning, building, and commissioning the factory.

This collaborative structure aligns the interests of all stakeholders around the common goal of industrial revitalization and can attract support from international development funds focused on reconstruction.

Securing Land and Infrastructure

The ideal location for the factory is within the Aleppo Industrial City itself. This offers proximity to the primary customer base, reducing transportation costs and logistical headaches.

A 50-100 MW production facility requires significant land for the main production hall, warehousing for raw materials and finished goods, and administrative offices. The building requirements for a solar module factory are specific, demanding proper floor loading capacity, ceiling height, and a climate-controlled environment to ensure high-quality production.

Technology and Line Setup: A German Engineering Approach

The heart of the project is the production line. A turnkey solution from an experienced engineering firm ensures the facility is built to international standards, capable of producing high-efficiency, durable solar modules.

The process includes:

-

Factory Layout and Design: Optimizing the flow of materials from entry to exit.

-

Machine Selection: Procuring and integrating an overview of solar module production machines from leading global suppliers, including stringers, laminators, and testers.

-

Installation and Commissioning: On-site management of the entire setup process by experienced engineers.

-

Staff Training and Knowledge Transfer: Equipping the local workforce with the skills needed to operate and maintain the machinery.

This comprehensive approach allows the investor to focus on business strategy while the technical partner guarantees a fully operational, state-of-the-art facility.

Market Strategy: Supplying the Engine of Reconstruction

The primary market for the factory’s output is clear and immediate: the hundreds of existing and planned factories within the Aleppo Industrial Zone.

-

Phase 1: Captive Industrial Market: The initial focus would be on equipping businesses in Sheikh Najjar with rooftop or ground-mounted solar installations, providing a stable, built-in customer base.

-

Phase 2: Regional Expansion: Once this demand is met, the factory can expand sales to the wider regional market, including commercial, agricultural, and residential customers.

-

Phase 3: Governmental and NGO Projects: The factory can become a key supplier for large-scale solar projects aimed at restoring public infrastructure like hospitals, schools, and water pumping stations.

The value proposition is compelling: a high-quality, locally produced solar module that offers a faster, more secure, and ultimately more profitable path to energy independence than relying on diesel.

Frequently Asked Questions (FAQ)

What is the typical investment for a 50-100 MW factory?

Investment levels vary based on the degree of automation and technology choices, but a project of this scale requires a significant capital investment. An exact figure depends on a detailed business plan. Educational materials at pvknowhow.com provide frameworks for understanding these investment requirements.

How long does it take to get a factory operational?

With a turnkey partner managing the process, a factory can go from a signed contract to the start of production in approximately 12 to 18 months, depending on logistics and local administrative hurdles.

How many employees are needed for a factory of this size?

A semi-automated 50-100 MW facility typically requires 100 to 200 employees for production, maintenance, administration, and sales, creating valuable local employment.

Why not just import solar panels?

While importation is an option, a local factory offers superior long-term benefits:

- Supply Chain Security: It eliminates dependency on international shipping and potential import tariffs.

- Job Creation: It creates skilled manufacturing jobs directly within the community it serves.

- Customization: The factory can tailor products to local environmental conditions.

- Economic Development: It anchors a high-tech industry in the region, fostering further technological growth.

Conclusion: From Blueprint to Reality

The reconstruction of the Aleppo Industrial Zone requires more than rebuilding structures; it requires restoring its fundamental infrastructure, starting with power. A local solar module manufacturing plant is not only a commercially sound investment but also a powerful catalyst for broad-based economic recovery. It is a strategic asset that empowers an entire industrial ecosystem.

For entrepreneurs and investors, the path may seem complex. However, the core challenge is not technical expertise but strategic planning and execution. With the right guidance and partners, a project of this magnitude is both achievable and essential for unlocking the region’s immense industrial potential. For those beginning this journey, the first step is building a foundational understanding of what it takes to start a solar factory guide.

Download the Aleppo PV Manufacturing Plant Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.