An investor considering a solar module factory often focuses first on machinery, financing, and location. Yet long-term success often hinges on a less tangible asset: the local workforce.

In a country like Tajikistan, with its unique economic and educational landscape, a thorough assessment of the local technical labor pool isn’t just a preliminary step—it’s a cornerstone of a viable business plan. The question isn’t whether talent exists, but how to identify, train, and retain it effectively.

Tajikistan presents a compelling case. Its reliance on hydropower makes it vulnerable to climate-induced energy shortages, creating a significant domestic need for solar energy. With abundant sunshine, averaging between 2,100 and 3,100 hours annually, and strong government support for renewables, the market opportunity is clear. Capitalizing on this opportunity depends on a self-sufficient, highly skilled local team capable of operating a modern manufacturing facility.

Evaluating the Existing Talent Pool: Strengths and Gaps

Understanding the local labor market helps an investor anticipate challenges and build a realistic human resources strategy. Tajikistan’s workforce has a distinct profile shaped by its history and demographics.

Foundational Strengths

The country offers several key advantages for an investor looking to establish a manufacturing base:

-

A Strong Engineering Tradition: Tajikistan has a legacy of technical education, with institutions like the Tajik Technical University producing graduates in mechanical, electrical, and civil engineering. This provides a pool of candidates with a strong theoretical foundation.

-

A Young and Eager Population: With over half its population under the age of 25, Tajikistan has a large demographic of young people entering the workforce. This motivated group is eager to learn new skills, offering the opportunity to build a team from the ground up and train it for modern manufacturing processes.

-

High Trainability: Experience from J.v.G. turnkey projects in similar markets shows that candidates with solid engineering fundamentals can be quickly trained in the specifics of photovoltaic technology. The core principles of industrial automation, quality control, and process management are transferable.

Identifiable Skill Gaps

While this foundation is strong, an investor must also plan for the specific gaps between existing qualifications and the demands of a modern solar module factory:

-

Limited Experience in Automated Manufacturing: The primary challenge is the lack of hands-on experience with the sophisticated, automated machinery used in solar module production. Theoretical knowledge from university must be matched with practical, on-the-floor operational skills.

-

Outdated Curricula: In some cases, vocational and university programs may not have kept pace with rapid technological advancements in the renewable energy sector. As a result, even qualified engineers will require specialized training on current PV technology and manufacturing standards.

-

The ‘Brain Drain’ Phenomenon: Like many countries in the region, Tajikistan experiences significant labor migration. The key strategic challenge is to create a work environment with the competitive compensation and career development opportunities needed to retain top talent.

Building a Skilled Workforce: A Practical Framework

Successfully navigating these gaps calls for a deliberate, structured approach to workforce development. The goal is to transform promising candidates into a proficient, self-sufficient production team.

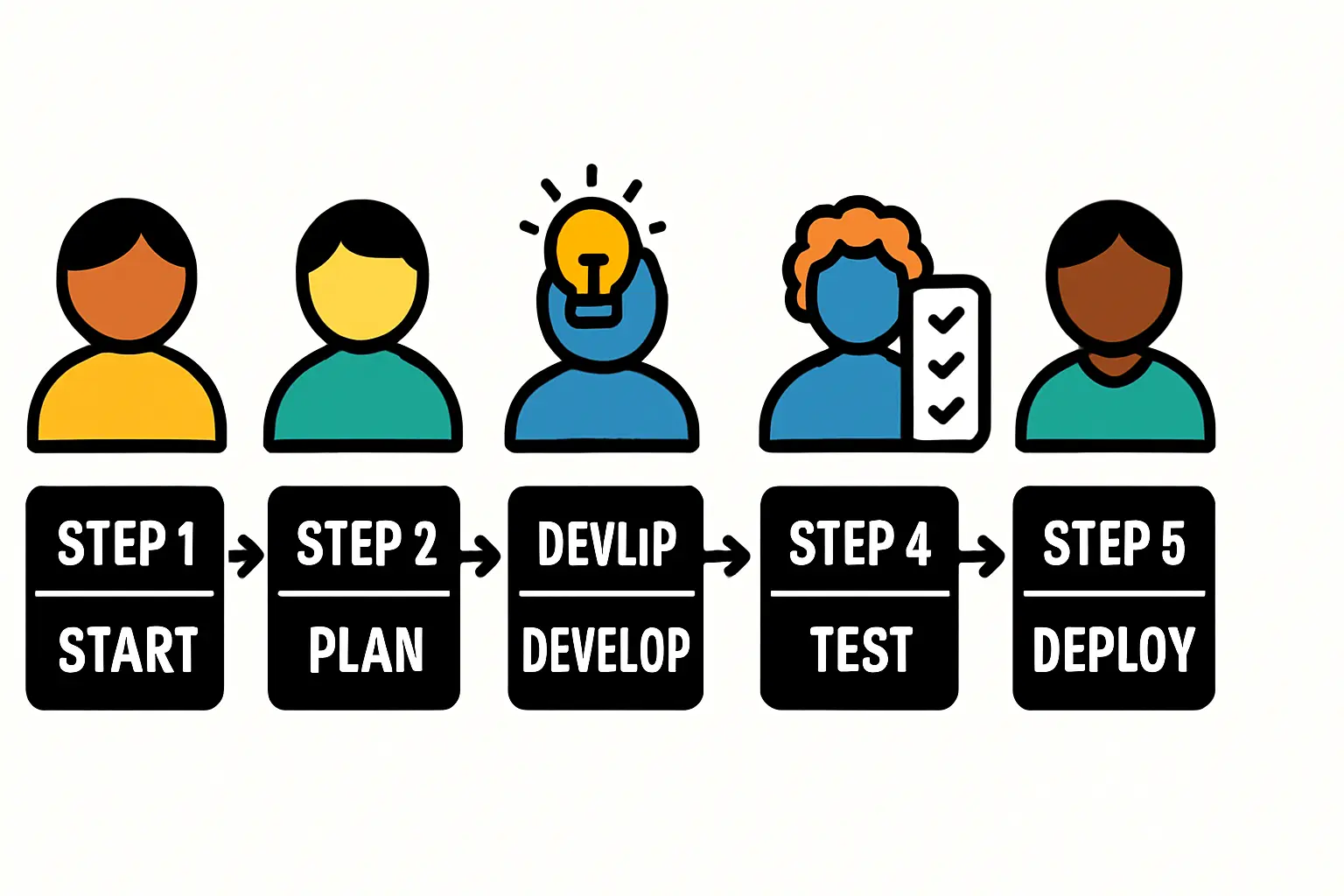

Step 1: Strategic Recruitment

The recruitment process should prioritize aptitude and foundational knowledge over direct PV experience, which is unlikely to be found locally. Ideal candidates often possess:

-

Degrees in Relevant Fields: Electrical engineering for roles involving junction box application and testing; mechanical engineering for machine operation and maintenance.

-

Problem-Solving Skills: The ability to troubleshoot issues with machinery and processes is more valuable than rote knowledge.

-

A Commitment to Quality: A detail-oriented mindset is crucial for maintaining the high-quality standards required for module certification.

An investor should focus on identifying individuals who demonstrate a capacity to learn and adapt. These are the future leaders of the production floor.

Step 2: Comprehensive, Hands-On Training

A dedicated training program is non-negotiable. This program should be a core component of the initial factory setup, often delivered by the equipment supplier. A common challenge for investors is bridging the gap between theoretical knowledge and the essential skills for daily operations.

A best-practice training model involves several stages:

-

Classroom Instruction: Covering the fundamentals of photovoltaic science, module components, and the production process from start to finish.

-

On-the-Floor Training: Engineers and technicians from the machinery supplier work side-by-side with new local hires, demonstrating each step of the process on the actual equipment. This is a critical phase of a turnkey solar module production line installation.

-

Process Ownership: Gradually transitioning responsibility to the local team, with external experts moving into a supervisory and support role.

This method ensures that by the time the factory is commissioned, the local team is not just familiar with the machines but is fully capable of operating and maintaining them independently.

Step 3: Long-Term Retention and Development

Recruiting and training are only the beginning. To protect the investment made in the workforce, a clear retention strategy is essential. This includes:

-

Competitive Compensation: Researching local and regional salary benchmarks to offer a package that reduces the incentive for skilled labor to migrate.

-

Career Pathways: Creating opportunities for advancement—from operator to line supervisor to production manager—gives employees a long-term vision within the company.

-

Continuous Improvement: Fostering a culture of ongoing learning to keep the team’s skills current with evolving industry standards.

By investing in its people, a company not only improves its operational efficiency but also builds a reputation as a premier local employer—a reputation that helps attract the best new talent in the future.

Financial and Operational Considerations

A well-trained local workforce has a direct, positive impact on a project’s financial viability. While initial training is a necessary investment, it significantly reduces long-term labor and operational costs by minimizing the need for expensive, long-term expatriate staff.

For a typical 20-50 MW solar module factory, a team of 25 to 35 employees across two shifts can manage the entire production process. This scale is well-suited to the labor dynamics in Tajikistan. The overall human resources strategy should be an integral part of the initial factory planning process, ensuring that recruitment timelines and training budgets are properly accounted for from day one.

Frequently Asked Questions

What academic backgrounds are most suitable for solar module production?

Engineers with degrees in Electrical Engineering, Mechanical Engineering, and Industrial Engineering are typically the best fit. Technicians from vocational schools with training in electronics or mechanics also make excellent candidates for operator roles.

Is it necessary to hire foreign experts to run the factory?

It is standard practice to have foreign experts on-site during the installation, commissioning, and initial ramp-up phases to lead the training. However, the primary objective should be to transition to a fully local management and operational team within the first 6-12 months.

How long does it take to train a new production team?

A structured training program can typically bring a new team to full operational competence within 3 to 4 months. This includes both classroom learning and intensive, hands-on practice on the production line.

How does investing in local training impact project risk?

Investing in a local workforce significantly de-risks the project. It ensures operational continuity, reduces dependency on foreign personnel, lowers long-term operating expenses, and builds positive relationships with the local community and government—factors that are crucial for sustainable success.

The Path to a Self-Sufficient Solar Workforce

The potential for solar module manufacturing in Tajikistan is substantial, driven by clear market needs and a supportive policy environment. While the local labor pool may lack direct experience in photovoltaics, it has the foundational technical aptitude and motivation required for success.

For the international investor, the key is to view workforce development not as an obstacle, but as a strategic investment. Through a rigorous process of recruitment, hands-on training, and long-term retention, an investor can build a world-class manufacturing team in Tajikistan. With the right guidance and a structured plan, this local talent becomes the engine that drives the factory’s productivity and long-term profitability.