An entrepreneur planning to establish a solar module factory often focuses on core production machinery, the material supply chain, and the skilled labor required. The factory building is designed, logistics are mapped out, and the business plan appears solid.

Yet one of the most fundamental inputs—a stable and continuous supply of electricity—is frequently underestimated, especially in regions with developing power grids.

In Tanzania, where businesses report an average of several power outages a month, this oversight can become the single greatest threat to a manufacturing operation. For a high-tech facility like a solar module factory, an unreliable grid is more than an inconvenience; it is a direct challenge to profitability, product quality, and the viability of the entire investment. This article outlines a strategic approach to power infrastructure that turns this critical vulnerability into a source of operational resilience.

The Critical Challenge: Grid Instability in an Industrial Context

The national power grid in many emerging economies, including Tanzania, faces significant challenges. These often stem from a combination of aging infrastructure, reliance on climate-dependent sources like hydropower, and rapidly growing demand that outpaces supply. For a solar module manufacturer, the consequences are immediate and severe.

Key Impacts of Unreliable Power:

-

Production Halts: Sensitive automated equipment, such as cell stringers and laminators, requires uninterrupted power to function. An unexpected outage stops the entire production line, leading to missed output targets and delayed shipments.

-

Equipment Damage: Sudden power surges or drops can damage delicate electronic components within the manufacturing machinery, leading to expensive repairs and extended downtime.

-

Material Wastage: A power failure during a critical process, like the lamination cycle which takes approximately 20 minutes under specific heat and pressure, can ruin an entire batch of modules. These materials must be discarded, directly impacting the cost of goods sold.

-

Dependence on Diesel: The conventional solution—diesel generators—presents its own set of challenges, including high and volatile fuel costs, significant maintenance requirements, and environmental drawbacks.

This reliance on an unstable external factor creates an operational risk that can undermine even the most well-planned business. The solution is to internalize control over the power supply.

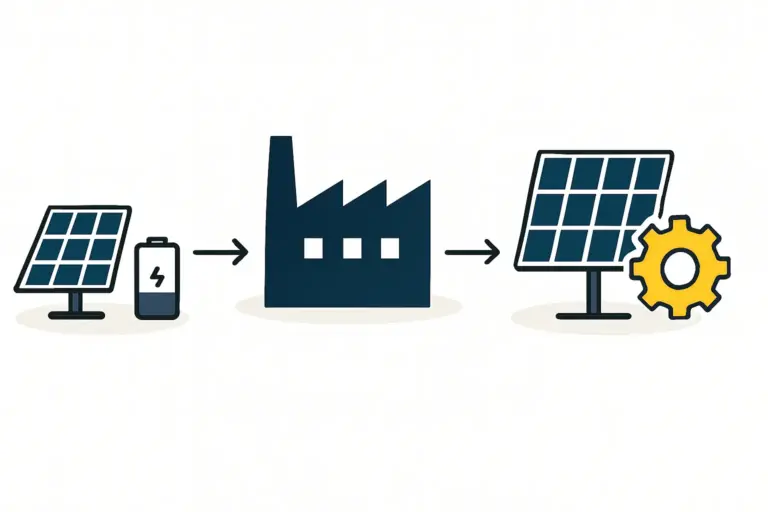

A Self-Sufficient Solution: The Captive Solar-Plus-Storage System

The most robust strategy for a solar module factory is to generate its own reliable electricity using a ‘captive’ power plant. Ironically, the best way to secure the manufacturing of solar modules is with solar energy itself, augmented by modern energy storage technology.

A captive solar-plus-storage system is an independent power plant located on-site, designed specifically to meet the factory’s energy demands. It operates in parallel with the grid, using it as a final backup rather than a primary source.

Core Components of the System:

-

Solar PV Array: Typically installed on the factory’s expansive rooftop, this array serves as the primary power generator during daylight hours.

-

Battery Energy Storage System (BESS): This is the heart of the reliability solution. The BESS stores excess solar energy generated during the day and discharges it to power the factory at night or, crucially, to provide instantaneous, seamless power during a grid outage.

-

Hybrid Inverters: These advanced devices act as the system’s brain, managing the flow of energy between the solar panels, batteries, factory equipment, and the grid. They ensure power is drawn from the most economical source at any given moment.

-

Backup Generator: While the solar and battery system will handle the vast majority of needs, a smaller diesel generator can be retained as a final layer of redundancy for prolonged periods of inclement weather or system maintenance.

During the day, the solar panels directly power the production line while simultaneously charging the batteries. As evening approaches or if the grid fails, the BESS automatically takes over, ensuring the factory’s operations continue without a single moment of interruption.

Key Business Advantages of a Captive Power System

Adopting a self-sufficient power strategy goes far beyond simply keeping the lights on. It delivers tangible business advantages that strengthen the entire enterprise.

Operational Continuity and Predictability

The primary benefit is the near-total elimination of production downtime caused by external grid failures. This allows for consistent manufacturing schedules, predictable output, and reliable fulfillment of customer orders—a key competitive differentiator.

Cost Control and Financial Hedging

By generating its own electricity, a factory insulates itself from rising commercial electricity tariffs and the unpredictable price of diesel fuel. The cost of solar energy is fixed for the 25+ year lifespan of the panels, making long-term financial planning far more accurate. Although this system represents a significant part of the project’s overall solar factory investment costs, it is a strategic investment in cost stability.

Enhanced Product Quality

Manufacturing high-performance solar modules requires absolute precision. Stable, high-quality power ensures that sensitive machinery like electroluminescence (EL) testers and solar simulators operate within their exact technical specifications. This leads to better quality control, lower defect rates, and a more reliable final product.

Improved Bankability

When seeking financing, a business plan that proactively mitigates a primary operational risk—such as power instability—is viewed much more favorably by investors and lending institutions. An independent power solution demonstrates thorough planning and a commitment to operational excellence.

Planning and Implementation Considerations

Integrating a captive power plant is not an afterthought; it must be a core component of the initial planning phase when you are exploring how to go about starting a solar module factory.

-

Conduct a Detailed Energy Audit: The first step is to calculate the precise energy consumption of the entire facility. This requires an analysis of every piece of equipment in the turnkey production line—from the stringers and laminators to the HVAC systems and office lighting—to determine peak and average load requirements.

-

Right-Size the System: Based on the audit, an engineering team can accurately size the PV array and BESS. The goal is not necessarily 100% autonomy, which can be cost-prohibitive, but an optimized system (e.g., 95-99% autonomy) that provides the best balance of reliability and return on investment.

-

Integrate with Facility Design: The power system must be incorporated into the initial architectural plans. This includes ensuring the roof structure can support the solar array and allocating dedicated, climate-controlled space for the batteries and inverters, which are key factory building requirements.

Experience from J.v.G. Technology GmbH turnkey projects shows that a 50 MW per year solar module factory typically requires a captive power plant of between 500 kWp and 1 MWp, a system that can often be fully accommodated on the factory’s rooftop.

Frequently Asked Questions (FAQ)

Is it possible to rely 100% on a captive solar system?

While technically feasible, designing a system for 100% autonomy to cover worst-case scenarios (e.g., several consecutive cloudy days) can significantly increase battery costs. A more economically sound approach is to design for 95-99% self-sufficiency, using the grid or a small backup generator as a low-cost final safety net.

How much space is required for the solar panels and batteries?

The physical footprint is manageable. For a typical 50 MW production line, the required solar array can usually fit on the factory’s rooftop space. The Battery Energy Storage System (BESS) is often housed in a standard shipping container or a dedicated room within the facility.

What is the typical payback period for such an investment?

The return on investment depends on several local factors, primarily the cost of grid electricity and diesel fuel. In a market like Tanzania, with high solar irradiation and relatively high commercial power costs, the payback period for a captive solar-plus-storage system can be compelling, often falling within a 5 to 8-year range.

Can this system sell excess power back to the grid?

The ability to sell surplus energy depends on national and local utility regulations, such as net-metering or feed-in-tariff policies. While this can provide an additional revenue stream, the primary objective for an industrial facility remains operational self-sufficiency and resilience.

Conclusion: Building a Resilient Foundation for Success

For an entrepreneur entering the solar manufacturing sector in Tanzania, the stability of the local grid presents a significant business risk that cannot be overlooked.

By implementing a captive solar-plus-storage system, a factory owner can turn this external vulnerability into a key operational strength. This strategic investment ensures uninterrupted production, stabilizes operational costs, improves product quality, and ultimately builds a more resilient and bankable business. Engineering a reliable power supply from day one is a foundational step toward long-term success in the competitive global solar market.