For an investor evaluating the burgeoning solar market in Tanzania, the opportunity is clear. With abundant solar irradiation of 4–7 kWh per square meter daily and a national goal to achieve 85% electrification by 2025, the demand for solar energy solutions is undeniable.

A successful venture, however, depends on more than market opportunity—it requires operational excellence. A critical, yet often underestimated, element of this is establishing a resilient and cost-effective supply chain for raw materials.

Whether to source components locally or import them is not merely a logistical choice; it is a strategic one that will define a factory’s cost structure, production timeline, and long-term viability. This analysis examines the practicalities of building a supply chain for a solar module assembly plant in Tanzania, providing a framework for these strategic decisions.

The Strategic Importance of Supply Chain Decisions in Tanzania

Tanzania’s commitment to renewable energy, underscored by policies like the National Energy Policy 2015 and the Power System Master Plan 2020, creates a supportive environment for investment. Yet, this high-level support must be paired with a granular operational strategy.

With over 70% of the population still lacking access to electricity, the pressure to deploy solutions quickly and affordably is immense. A well-planned supply chain directly addresses this challenge by managing costs, ensuring component quality, and guaranteeing production continuity. Tanzania’s geography, with its primary port in Dar es Salaam, dictates the flow of imported goods, while its developing industrial base presents both challenges and opportunities for local sourcing. Navigating this landscape effectively is fundamental to success.

Analyzing the Bill of Materials: A Component-by-Component Evaluation

A standard photovoltaic module consists of several key components. Sourcing each one presents a distinct set of considerations for an enterprise based in Tanzania. Understanding the local feasibility for each part is the first step in designing an optimal supply chain.

Aluminum Frames: The Local Potential

The aluminum frame provides structural integrity to the module. While Tanzania possesses significant bauxite reserves—the primary ore for aluminum—the current reality is that raw aluminum profiles are largely imported.

Yet this presents an immediate opportunity for local value addition. Importing aluminum profiles and fabricating the frames locally (cutting, drilling, and assembling) is highly feasible. This approach can reduce shipping costs for bulky finished frames and create local employment. The critical factor is implementing stringent quality control to ensure precise dimensions and durable construction.

Solar Glass: The Import Imperative

The front glass of a solar module is not standard glass; it is highly specialized, low-iron, tempered glass designed for maximum light transmission and durability. Currently, there is no local production of solar-grade glass in Tanzania or the wider East African region. This component must be imported from established international manufacturers. Investors must factor the logistics of shipping a fragile, heavy product into their planning.

Junction Boxes: A Hybrid Opportunity

The junction box, which houses the bypass diodes and connects the module to the wider system, offers a hybrid sourcing model. While the specialized electronic components (diodes, connectors) must be imported, the plastic housing could potentially be sourced from local plastic molding companies.

Thorough due diligence is required to ensure a local supplier can meet rigorous quality standards, such as specific IP (Ingress Protection) ratings and the use of UV-stabilized materials. A more common approach is to import complete, certified junction boxes initially, while exploring local assembly partnerships as the business scales.

Encapsulants (EVA) & Backsheets: The Global Standard

Ethylene Vinyl Acetate (EVA) sheets and the backsheet are highly specialized polymer products, the result of complex chemical engineering processes. There is no local manufacturing capacity for these materials in Tanzania, meaning they must be imported from global suppliers.

Solar Cells: The Heart of the Module

Solar cells are the core technological component of the module. Their production is a capital-intensive, high-technology process concentrated in a few key regions globally. For any new solar module assembly facility in Tanzania, importing high-quality solar cells is the only viable option.

Local Sourcing vs. Global Importing: A Cost-Benefit Framework

This component analysis makes it clear that an investor’s supply chain strategy will inevitably be a hybrid model. The key is to determine the right balance, which hinges on a trade-off between cost, quality control, and logistical complexity.

The Case for Importing All Components (Initial Phase)

Advantages:

- Quality Assurance: Access to internationally certified components from established suppliers.

- Simplicity: Dealing with a limited number of experienced suppliers streamlines procurement.

- Economies of Scale: Large global manufacturers offer competitive pricing.

Disadvantages:

- Logistical Costs & Delays: High costs for shipping and insurance, with significant lead times and potential customs complexity.

- Currency Fluctuation: Exposure to foreign exchange volatility.

- Working Capital: More capital is tied up in inventory during transit.

The Case for a Hybrid Model (Mature Phase)

Advantages:

- Reduced Logistics Costs: Local fabrication of bulky items like frames significantly lowers freight expenses.

- Shorter Lead Times: Localizing parts of the supply chain can improve production agility.

- Local Economic Impact: Contributes to local industry and may be viewed favorably by government bodies.

Disadvantages:

- Supplier Development: Requires significant investment in vetting and developing local suppliers.

- Quality Control Risk: Demands robust internal processes to ensure locally fabricated parts meet specs.

- Limited Scale: Local suppliers may not initially offer the same economies of scale.

Practical Considerations for Investors

Establishing a solar assembly plant requires a pragmatic approach. The supply chain strategy should evolve with the business.

Feasibility and Due Diligence

Before committing to local sourcing for any component, a thorough feasibility study is non-negotiable. This involves on-the-ground visits to potential fabrication shops to assess their equipment, quality control processes, and capacity. These findings will heavily influence your total required investment.

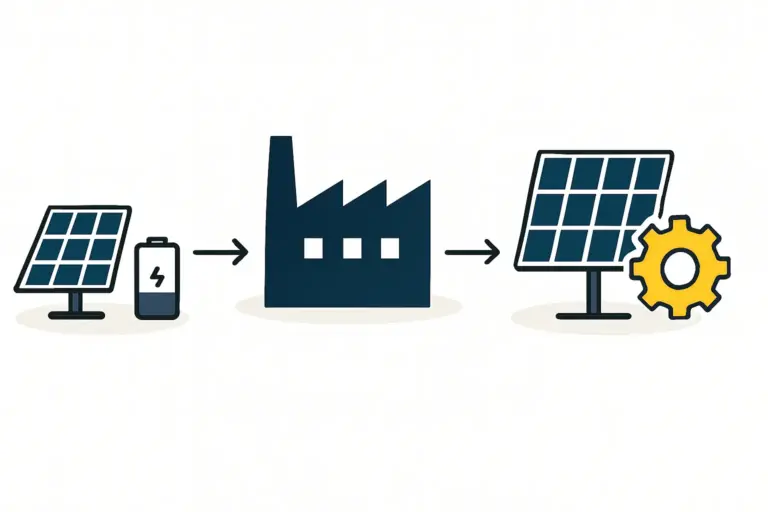

A Phased Approach to Localization

Experience from turnkey projects shows that a phased strategy is often most effective:

-

Phase 1: Launch with Fully Imported Components. Start operations using a complete bill of materials from a single, reliable international supplier. This de-risks the launch, ensures product quality, and allows the team to focus on mastering assembly.

-

Phase 2: Introduce Local Frame Fabrication. Once production is stable, the first logical step toward localization is the aluminum frames. This offers the most immediate impact on reducing shipping costs.

-

Phase 3: Explore Further Local Assembly. With a mature operation, investors can explore the local assembly of junction boxes or sourcing of packaging materials, continually optimizing the cost structure.

Frequently Asked Questions (FAQ)

What are the biggest supply chain risks in Tanzania?

The primary risks include potential delays at the port and during customs clearance, inland transportation challenges, currency fluctuations affecting import costs, and ensuring consistent quality from any new local suppliers.

Can a new factory realistically produce all components locally?

No. Core technology components like solar cells, solar-grade glass, and specialized polymers (EVA, backsheet) must be imported. Meaningful localization focuses on bulky components like frames and potentially the assembly of junction boxes.

Are there government incentives for using local suppliers in Tanzania?

The Tanzanian government encourages local content. While specific financial incentives must be verified with agencies like the Tanzania Investment Centre (TIC), a business model with local value addition is generally viewed more favorably.

How long does it take to ship components to Tanzania?

Sea freight from major manufacturing hubs in Asia or Europe to the port of Dar es Salaam typically takes between 4 to 8 weeks. This does not include potential delays in port handling or customs clearance.

Conclusion: Building a Resilient Supply Chain for a Tanzanian Solar Venture

Successfully establishing a solar module assembly plant in Tanzania requires a supply chain strategy that is both ambitious and pragmatic. The journey begins with a clear-eyed assessment of which components must be imported and which present a realistic opportunity for local fabrication.

By starting with a reliable, fully imported supply chain and then systematically pursuing localization for components like aluminum frames, an investor can build a resilient, cost-competitive operation. This phased approach mitigates risk while positioning the venture to capitalize on the immense potential of Tanzania’s solar energy future. Careful planning and expert guidance are paramount in turning this opportunity into a sustainable and impactful business.