When evaluating a new manufacturing venture, business leaders often focus on primary costs like labor, land, and logistics. Yet a critical variable that can significantly impact long-term profitability is often overlooked: the true cost and reliability of essential utilities.

In a manufacturing-intensive environment like Thailand’s industrial estates, understanding the nuances of electricity and water tariffs isn’t merely an administrative task. It is a strategic necessity for accurate financial forecasting.

A business plan that assumes a simple, flat rate for electricity is fundamentally flawed. The reality is a dynamic system of tariffs, peak-hour charges, and fuel adjustment costs that can introduce significant volatility to operational expenditures. This article breaks down the utility landscape in Thailand’s major industrial zones, offering the foundational knowledge needed for robust financial modeling.

The True Cost of Power: A Closer Look at Industrial Electricity Tariffs

The price of electricity for industrial users in Thailand is not a single figure but a composite rate determined by several factors. Understanding them is essential for accurate cost forecasting. This structure is managed by the Provincial Electricity Authority (PEA) and the Metropolitan Electricity Authority (MEA), with rates approved by the Energy Regulatory Commission (ERC).

Key Components of the Electricity Bill

-

Base Tariff: This foundational charge per kilowatt-hour (kWh) varies based on voltage level and consumption patterns.

-

Fuel Adjustment Charge (Ft Rate): This is arguably the most critical and variable component. The Ft rate is adjusted every four months to reflect changes in global fuel prices (primarily natural gas, which accounts for about 60% of Thailand’s power generation), currency exchange rates, and national power purchasing costs. For example, during periods of high global energy prices, the Ft rate can increase substantially, driving up electricity bills. In late 2022 and early 2023, the Ft rate reached historic highs, creating significant pressure on manufacturers’ operating margins.

-

Time of Use (TOU) Tariffs: Many industrial users operate on a TOU tariff structure, which prices electricity differently depending on the time of day and day of the week.

On-Peak Hours (e.g., 9:00 AM – 10:00 PM, Monday-Friday): Electricity is most expensive during these periods of high demand, with typical rates over 4.5 THB/kWh.

Off-Peak Hours (e.g., 10:00 PM – 9:00 AM, Monday-Friday, and all day on weekends/holidays): Electricity is significantly cheaper, often priced around 2.6 THB/kWh.

For a manufacturing facility, particularly one with energy-intensive processes, shifting production schedules to maximize off-peak consumption can lead to substantial cost savings.

Water Tariffs: A Secondary but Significant Operational Cost

While electricity represents the larger utility expense, water is another crucial input with its own variable cost structure. Water tariffs in industrial estates, such as those managed by the Industrial Estate Authority of Thailand (IEAT), are typically tiered.

A common tiered structure might look like this:

Tier 1: A base rate for an initial block of consumption (e.g., the first 1,000 cubic meters).

Tier 2: A higher rate for the next block of consumption.

Tier 3: The highest rate for consumption above a certain threshold.

This progressive pricing model incentivizes water conservation. For factories with high water usage for cooling, cleaning, or processing, failing to account for these tiered rates can lead to budget overruns.

Beyond the Bill: The Impact of Grid Reliability on Production

Cost is only one part of the equation; reliability is the other. In precision manufacturing, an unexpected power outage can be far more costly than the lost production time, leading to equipment damage, material waste, and quality control failures.

Thailand’s grid is generally considered robust, especially within the Eastern Economic Corridor (EEC). However, localized outages and voltage fluctuations can still occur. Key metrics used to measure grid reliability include:

-

SAIDI (System Average Interruption Duration Index): This measures the average total duration of interruptions for each customer. A lower SAIDI figure indicates shorter outages. In major Thai industrial zones, SAIDI is often comparable to that of developed nations.

-

SAIFI (System Average Interruption Frequency Index): This measures the average number of interruptions a customer experiences. A lower SAIFI is better.

While national averages are positive, investors should seek specific reliability data for the particular industrial estate they are considering. Even a momentary power sag can disrupt sensitive machinery, making an uninterruptible power supply (UPS) for critical systems and a backup power strategy essential.

Mitigating Risk: Backup Power and On-Site Generation

To protect against grid instability and manage volatile energy costs, many industrial facilities invest in their own power solutions.

-

Diesel Generators: The traditional solution for backup power, providing reliability during grid outages. However, they come with high fuel and maintenance costs and produce significant emissions.

-

Rooftop Solar PV: Installing a rooftop solar system is an increasingly popular strategy. It allows a facility to generate its own electricity during daylight hours, reducing consumption from the grid during expensive on-peak periods. This also serves as a hedge against rising Ft rates and enhances a company’s environmental credentials. Combining solar with a battery storage system can provide both cost savings and a reliable backup power source.

Experience from turnkey projects, such as those by J.v.G. Technology GmbH, underscores that a thorough analysis of a site’s utility costs and grid performance is a standard part of the factory planning process.

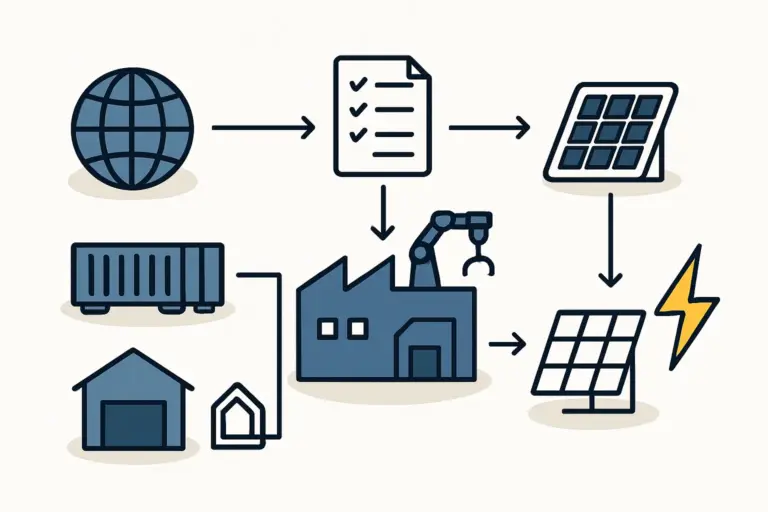

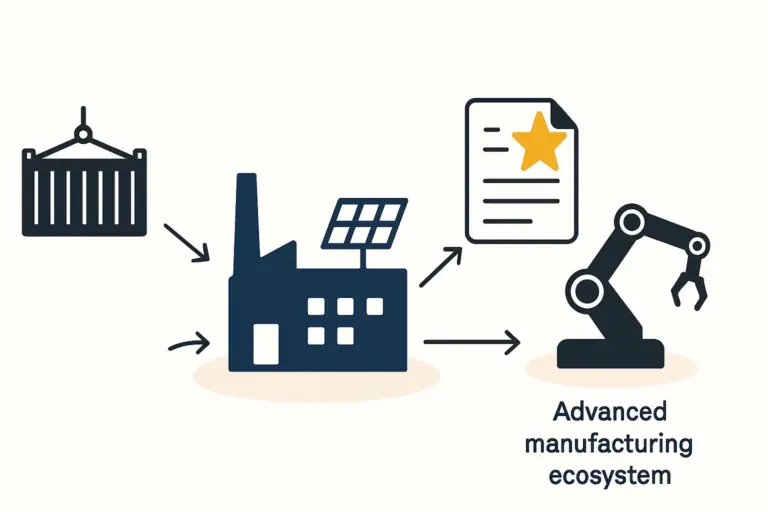

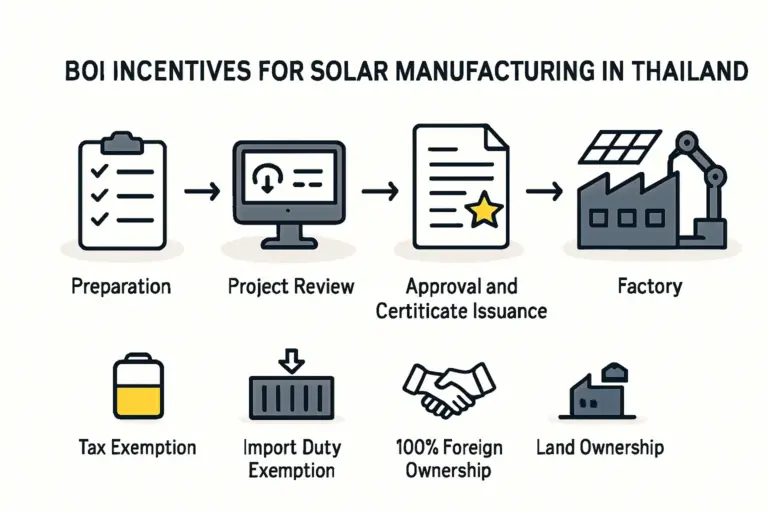

Case Study Context: Why Thailand Remains an Attractive Hub

Despite the complexities of its utility costs, Thailand continues to be a leading destination for foreign direct investment in manufacturing. The country’s Board of Investment (BOI) offers a wide range of tax and non-tax incentives for strategic industries, which can help offset operational costs. Its strategic location at the heart of ASEAN provides excellent logistical access to regional and global supply chains.

The key for any investor is to enter with a clear understanding of the operational landscape. By properly modeling utility costs and planning for potential grid disruptions, a business can leverage Thailand’s strengths while mitigating its risks, creating a resilient and profitable manufacturing operation.

Frequently Asked Questions (FAQ)

What is the most significant factor affecting industrial electricity prices in Thailand?

The Fuel Adjustment Charge (Ft rate) is the most volatile and significant component. It is tied to global fuel prices, primarily natural gas, and is adjusted every four months, which can cause electricity bills to fluctuate significantly.

How can a new factory best manage Time of Use (TOU) tariffs?

By analyzing production processes to identify energy-intensive steps that can be scheduled during off-peak hours (nights and weekends). This single operational change can yield significant cost savings without any capital investment.

Are utility rates the same across all industrial estates in Thailand?

While the core tariff structure is set by national authorities like the PEA and MEA, there can be minor variations in administrative fees or infrastructure charges between different industrial estates. It’s always best to confirm the specific rates with the management of the chosen estate.

Is grid reliability a major concern for manufacturers in Thailand?

Generally, the grid within major industrial zones like the Eastern Economic Corridor (EEC) is highly reliable. However, for industries with zero tolerance for power interruptions, such as semiconductor or advanced electronics manufacturing, investing in on-site backup power and power conditioning equipment is standard practice.

Next Steps in Your Planning Process

Understanding the dynamics of utility costs and reliability is a foundational step in building a successful business case for a manufacturing plant in Thailand. This knowledge allows for a more accurate financial model, reducing unforeseen expenses and strengthening the overall investment proposal.

For those proceeding with plans, the next logical phase involves a detailed site selection analysis and the development of a comprehensive operational strategy. This includes everything from securing land and permits to designing the factory layout and production lines. A structured approach is essential for navigating this complex process efficiently.