For an entrepreneur considering solar module manufacturing in Tunisia, the European market presents a compelling opportunity. Europe is geographically close, culturally familiar, and economically significant. However, accessing this market is not merely a matter of logistics; it requires a deep understanding of its rigorous quality and safety standards.

Many new ventures underestimate the complexity of this step, assuming that proximity alone guarantees market entry. In reality, European buyers, distributors, and financiers operate on a foundation of trust built on standardized, verifiable proof of quality. This guide outlines the essential certification framework—specifically IEC standards and TÜV certification—that a Tunisian manufacturer must navigate to export solar modules to the European Union. Understanding this process is the first critical step in transforming a strategic location into a competitive advantage.

The Strategic Advantage: Why Manufacture in Tunisia for the EU Market?

Tunisia’s potential as a manufacturing hub for the European solar market rests on two pillars: geography and trade policy. Leveraged correctly, these factors can create a significant competitive edge over established Asian producers.

Geographic Proximity and Logistical Efficiency

Tunisia’s most straightforward advantage is its location. Shipping containers from Tunisia can reach major European ports like Marseille, Genoa, or Valencia in a matter of days, not weeks. This drastically reduces shipping costs and lead times, enabling a more responsive supply chain—a critical factor for project developers in Europe operating on tight deadlines.

Favorable Trade Agreements and Rules of Origin

Beyond logistics, Tunisia’s trade relationship with the EU provides a powerful financial incentive. The EU-Tunisia Free Trade Agreement, as part of the Pan-Euro-Mediterranean (PEM) Convention, allows for duty-free access to the EU market. This can translate into a cost advantage of over 10-15% compared to imports from regions subject to tariffs.

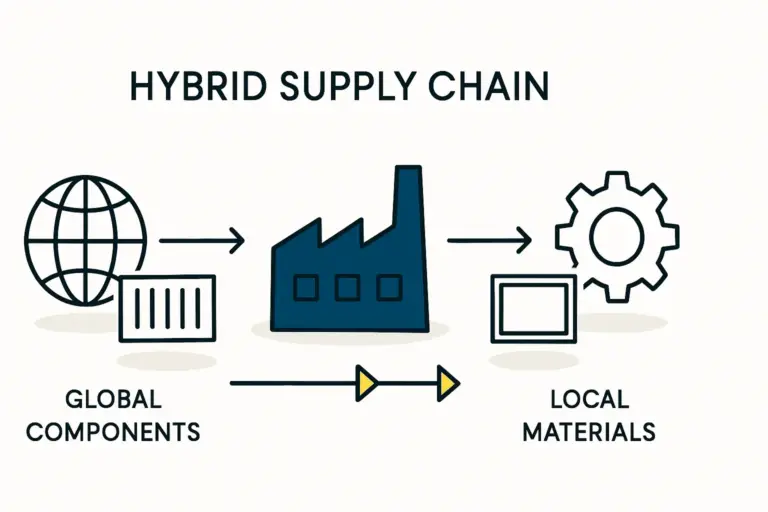

However, this benefit hinges on meeting ‘Rules of Origin.’ To qualify, a significant portion of the product’s value must be created within Tunisia. Simply importing all components for final assembly may not be sufficient. A successful strategy incorporates local value-add, such as using locally sourced aluminum frames or glass, and ensures the assembly process itself is substantial. This distinction is crucial for financial planning and supply chain design.

Understanding the EU’s Core Requirements for Solar Modules

To gain entry and acceptance in the EU market, a solar module must bear specific marks and certifications. These are not administrative formalities; they are proof of safety, reliability, and bankability.

The CE Mark: The Mandatory First Step

The CE mark is a mandatory conformity marking for products sold within the European Economic Area (EEA). By affixing the CE mark, a manufacturer declares that the product meets EU standards for health, safety, and environmental protection. For solar modules, this typically involves conformity with the Low Voltage Directive and the EMC Directive. It is a self-declaration and the absolute minimum requirement for legal market entry. However, for a high-value product like a solar panel, the mark on its own is commercially insufficient.

IEC Standards: The Global Language of Quality

The International Electrotechnical Commission (IEC) establishes the global technical standards for solar modules. Think of these standards as the universal engineering language that proves a module is designed and built to perform reliably for decades. The two most critical standards are:

-

IEC 61215 (Performance): This standard tests the module’s design and performance under various stressful conditions, including thermal cycling (extreme temperature swings), damp heat exposure, UV degradation, and mechanical load (wind and snow).

-

IEC 61730 (Safety): This standard focuses on the electrical safety of the module, ensuring it protects against electric shock, fire hazards, and personal injury over its lifetime.

Compliance with both IEC 61215 and IEC 61730 is the foundation of a credible, high-quality solar module. A robust solar panel quality control system is essential to meet and maintain these standards.

TÜV Certification: The Gold Standard of Market Trust

While the IEC sets the standards, an independent, accredited body must verify compliance. This is where certification bodies like TÜV Rheinland, VDE, or Intertek play a crucial role. Although not a government entity, certification from a respected institution like TÜV is a de facto requirement for commercial success in Europe.

A TÜV-certified module signals to a potential buyer, investor, or insurer that the product has been rigorously tested by a trusted third party and found to meet the highest international standards for safety and reliability. It is the key that unlocks project financing and large-scale distribution deals.

The Path to Certification: A Step-by-Step Overview

Achieving IEC certification from a body like TÜV is a structured process that requires meticulous planning and execution. Based on experience from J.v.G. turnkey projects, the typical timeline is between six and twelve months.

-

Establish a Quality Management System (QMS): Before producing test samples, the factory must implement a robust QMS, often certified to ISO 9001 standards. This ensures that every module produced will be consistent with the certified design.

-

Design and Produce ‘Golden Samples’: A batch of modules (typically 8-10) is produced specifically for testing. These ‘golden samples’ must fully represent the final commercial product, using the exact materials and processes intended for mass production. Using the right solar panel manufacturing machine list is fundamental to achieving this consistency.

-

Submit Samples for Laboratory Testing: The samples are sent to an accredited laboratory (e.g., TÜV), where they undergo the full battery of IEC 61215 and IEC 61730 tests. This is the most time-consuming phase.

-

Undergo the Factory Audit: While the modules are being tested, the certification body will send auditors to inspect the manufacturing facility. They verify that the QMS is being followed, production processes are controlled, and the factory is capable of consistently producing modules identical to the samples being tested.

-

Receive the Certification: If the modules pass all tests and the factory audit is successful, the certificate is issued. This certificate is typically valid for five years, contingent on annual surveillance audits.

The total investment required for a solar panel manufacturing plant should always account for the significant time and costs of this certification process.

Common Pitfalls for New Manufacturers in Tunisia

Navigating this landscape can be challenging. Newcomers often encounter several predictable obstacles:

-

Misunderstanding Rules of Origin: Assuming the Free Trade Agreement grants automatic duty-free access without designing a supply chain that maximizes local value creation.

-

Relying Solely on the CE Mark: Believing the mandatory CE mark is sufficient for market acceptance, only to find that distributors and financiers require full IEC/TÜV certification.

-

Inconsistent Production Quality: Achieving certification with ‘golden samples’ but failing to maintain the same level of quality in mass production, leading to high warranty claims and reputational damage.

-

Underestimating Timelines and Costs: Failing to budget for the 6-12 month certification process and its associated costs, which can cause delays in market entry and cash flow problems.

Frequently Asked Questions (FAQ)

What is the difference between IEC and TÜV?

IEC (International Electrotechnical Commission) is an organization that creates and publishes international standards (the ‘rulebook,’ like IEC 61215). TÜV is an independent company (a ‘referee’) that tests and certifies that a product follows the rules laid out in the IEC standards.

Is ISO 9001 required for IEC certification?

While not always strictly mandatory, having an ISO 9001 certified Quality Management System is highly recommended and often a prerequisite for most reputable certification bodies. It demonstrates a commitment to consistent quality.

How long is a TÜV certificate valid?

A solar module certificate is typically valid for five years. However, the certification body will conduct annual or biennial factory audits to ensure that the manufacturing process remains compliant.

Can a factory use components from Asia and still meet Rules of Origin?

Yes, it is possible. The key is the concept of ‘substantial transformation.’ If imported components (e.g., solar cells) are transformed into a new product (a finished solar module) through a complex assembly process in Tunisia, and sufficient local value is added (e.g., labor, frames, glass, overhead), the final product can qualify for Tunisian origin. This must be carefully documented.

What happens if a module fails one of the tests?

If a module fails a test, the manufacturer must identify the root cause, re-engineer the component or process, produce a new set of samples, and resubmit them for testing. This can lead to significant delays and additional costs.

Conclusion and Next Steps

For a Tunisian entrepreneur, the European solar market is a reachable and lucrative goal. The country’s strategic location and favorable trade agreements provide a unique foundation for success. However, this potential can only be realized through an unwavering commitment to meeting the world’s highest quality and safety standards.

The path through IEC and TÜV certification is not an obstacle but a roadmap. It provides a structured framework for building a manufacturing operation that is not just competitive on price, but built on a reputation for quality, reliability, and trust. For those exploring how to start a solar panel manufacturing business, mastering these requirements is a non-negotiable step toward building a bankable and sustainable enterprise. Navigating these standards requires careful planning and expert guidance, a process detailed in resources like the pvknowhow.com e-course.