An investor’s focus is naturally drawn to the advanced machinery, market projections, and financial models of a new solar module factory. However, the success of a multi-million dollar, 24/7 manufacturing operation often hinges on something far more fundamental: the reliability of the electrical socket on the wall and the water tap in the facility.

In emerging manufacturing hubs like Tunisia, overlooking the stability of local utility infrastructure is a critical—and potentially costly—oversight. This analysis explores the reality of power and water infrastructure within Tunisian industrial parks and offers a framework for investors to assess risks and plan for operational resilience from day one.

THE 24/7 IMPERATIVE IN SOLAR MANUFACTURING

Modern solar module production is not a business that can easily tolerate interruptions. The manufacturing process involves several time-sensitive stages, such as lamination and curing, that require uninterrupted power for extended periods.

A sudden power outage can lead to:

Material Waste: An entire batch of modules in a laminator can be ruined, leading to direct financial loss.

Equipment Damage: Abrupt shutdowns can harm sensitive robotics, testing equipment, and thermal processing units.

Reduced Throughput: Every hour of downtime directly impacts production targets, delaying the return on investment and affecting profitability.

Achieving the targeted output of a 20 MW, 50 MW, or larger facility demands continuous, stable operation. A thorough assessment of the local utility grid, then, is not just a preliminary check—it is a core component of business planning.

ANALYZING TUNISIA’S NATIONAL POWER GRID (STEG)

The state-owned Tunisian Company of Electricity and Gas (STEG) manages the country’s power generation and distribution. While the government has made significant investments to expand and modernize the grid, investors must understand the underlying challenges that can affect a 24/7 industrial operation.

The Challenge of Peak Demand

A primary concern is the significant strain on the grid during the hot summer months. Increased use of air conditioning by residential and commercial consumers creates dramatic spikes in electricity demand.

This seasonal pressure can lead to voltage fluctuations or, in some cases, government-mandated load shedding (planned blackouts) to prevent a system-wide collapse. For a solar factory, even a brief, unplanned outage can disrupt production for hours. Reports from STEG often highlight the ongoing challenge of balancing rapidly growing demand with the pace of infrastructure upgrades, particularly in regions with high industrial growth.

WATER SUPPLY RELIABILITY AND SONEDE

The reliability of the water supply, managed by the National Water Distribution Utility (SONEDE), is equally important. The solar module assembly process requires clean, demineralized water, primarily for washing glass panels before lamination. Any contaminants or supply interruptions can compromise the quality and longevity of the final product.

Tunisia, like much of North Africa, faces structural water scarcity. SONEDE works to manage this precious resource, but challenges remain with aging pipeline infrastructure and regional disparities in supply. A factory’s plans must account for potential water pressure drops or service interruptions, which could halt the entire production line.

INDUSTRIAL PARKS: A LOCATION-SPECIFIC ANALYSIS

Tunisia offers numerous industrial parks designed to attract foreign investment with the promise of ‘plug-and-play’ infrastructure. While these zones provide significant advantages, the quality and reliability of utility connections can vary dramatically from one park to another.

Experience from J.v.G. turnkey projects shows that an investor cannot assume that every designated industrial zone offers the same level of utility stability. Parks in established coastal hubs like Tunis or Sfax may have more robust and redundant connections compared to newer or more remote inland parks. Thorough on-the-ground due diligence is essential.

A detailed site selection process must involve direct engagement with the park administration, STEG, and SONEDE to obtain historical data on power quality, outage frequency, and water pressure for that specific location.

STRATEGIC CONTINGENCY PLANNING FOR OPERATIONAL RESILIENCE

Acknowledging these infrastructure risks is the first step. The second, more critical step is designing a facility that is resilient to them. This is a standard part of planning a turnkey production line.

On-Site Power Generation and Storage

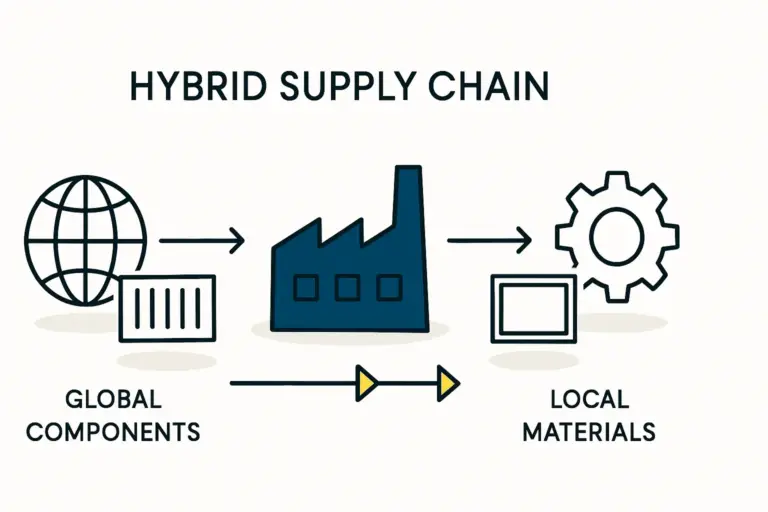

The most effective strategy is to reduce reliance on the grid. A hybrid power system is becoming a best practice for industrial facilities in regions with grid instability. This typically includes a Rooftop Solar PV System, a Battery Energy Storage System (BESS), and a Diesel Generator.

The factory’s own roof can generate a significant portion of its daytime electricity needs. Batteries can store excess solar energy or cheap off-peak grid power, providing instantaneous backup. A backup generator provides a final layer of security for critical machinery during a prolonged grid failure.

Uninterruptible Power Supply (UPS) for Critical Machinery

Even with backup systems, a momentary switchover can disrupt highly sensitive equipment like servers, PLCs, and testing devices. Installing dedicated UPS systems for these critical components ensures a truly seamless transition, protecting both data and hardware.

Water Management and Conservation

A factory can mitigate water supply risks by incorporating on-site water storage tanks and water recycling systems. Large tanks can provide a buffer of several days’ worth of water, while a closed-loop water treatment system for the module washing station significantly reduces daily water consumption and minimizes dependence on the external supply.

FREQUENTLY ASKED QUESTIONS (FAQ)

Is the power grid unreliable everywhere in Tunisia?

No. Reliability varies significantly by region and even by specific industrial park. Major economic centers generally have more stable infrastructure. The key is to conduct a location-specific assessment rather than relying on national averages.

How much extra investment is required for backup power and water systems?

The investment depends on the scale of the factory and the level of desired autonomy. A typical contingency plan, including solar, battery storage, and water tanks, may add 5–10% to the initial capital expenditure. However, this investment is often recovered quickly by preventing just a few major production stoppages.

Can a new factory operate completely off-grid?

While technically possible, it is generally not economically feasible for a large-scale manufacturing plant. The cost of a 100% off-grid power system capable of supporting 24/7 industrial loads would be prohibitive. The most practical approach is a hybrid system that uses the grid as its primary source but has robust on-site systems to ensure reliability.

CONCLUSION: BUILDING A RESILIENT FOUNDATION

The solar manufacturing industry in Tunisia offers a significant business opportunity. However, long-term success requires a clear-eyed assessment of operational realities. The stability of power and water is not a secondary detail; it is the foundation upon which a modern, 24/7 manufacturing facility rests.

By conducting thorough due diligence during site selection and proactively investing in on-site contingency systems, an investor can mitigate these fundamental risks. This foresight transforms a potential vulnerability into a source of competitive advantage, ensuring the facility remains productive and profitable regardless of external infrastructure challenges.