An entrepreneur considering a solar module factory in Tunisia will logically first assess the availability of machinery, financing, and materials. Yet a frequent oversight is the human element: where will the skilled technicians who operate the production line come from?

The assumption that a region needs a pre-existing pool of solar manufacturing experts can be a significant barrier. The reality, however, is more optimistic. The challenge isn’t a lack of capable individuals but the absence of a structured process for transforming a motivated local workforce into a highly proficient production team.

With a strategic approach to recruitment and training, establishing a world-class technical team in Tunisia is not only possible—it represents a significant competitive advantage.

The Tunisian Opportunity: A Favorable Landscape for Solar Manufacturing

Tunisia presents a unique and promising environment for new solar manufacturing ventures. This is no accident but the result of a convergence of government policy, demographic trends, and international support. Understanding this context is crucial for building a successful labor strategy.

Government Vision and Market Growth

The Tunisian government’s ‘Plan Solaire Tunisien’ (PST) is a clear indicator of national commitment, aiming to increase the share of renewable energy in the electricity mix to 35% by 2030. This ambitious target is expected to generate thousands of new jobs in the green energy sector, creating a strong pull for talent and supportive infrastructure. IRENA analysis suggests that Africa as a continent could create as many as 2 million green energy jobs by 2050, positioning Tunisia as a potential hub for this growth.

The Talent Paradox

A key feature of the Tunisian labor market is a paradox: a relatively high youth unemployment rate coexists with a large number of engineering and technical graduates produced annually. For a solar manufacturing investor, this isn’t a problem but a major opportunity. It points to a large, educated, and motivated talent pool ready to be engaged. The core task is to bridge the gap between their general technical education and the specific requirements of solar module production.

A Foundation of Technical Education

International collaboration has already laid a strong foundation. The German development agency GIZ, for example, has actively supported vocational training centers (Centres de Formation et d’Apprentissage – CFA) across Tunisia, with a focus on renewable energy skills. These institutions can become valuable partners in sourcing and pre-screening candidates for a new factory.

Defining the ‘Skilled’ Solar Technician: Beyond the Job Title

Before recruiting, it’s essential to define what ‘skilled’ truly means for a modern solar production line. This role doesn’t necessarily require a four-year engineering degree or prior solar experience. Instead, the most valuable attributes are often transferable skills and personal qualities.

A well-run factory relies on a comprehensive understanding of the entire solar module manufacturing process, from cell inspection to final testing. The ideal candidate for an operator or technician role possesses:

-

Process Discipline: The ability to follow standardized procedures meticulously is paramount for ensuring quality and consistency.

-

Attention to Detail: Small deviations in handling cells or applying materials can lead to significant performance issues.

-

Technical Aptitude: A basic understanding of mechanical or electronic principles is beneficial. Candidates with experience in related industries, such as electronics assembly or automotive manufacturing, often transition successfully.

-

Commitment to Quality: An inherent sense of pride in producing a high-quality product is a critical cultural element for the entire team.

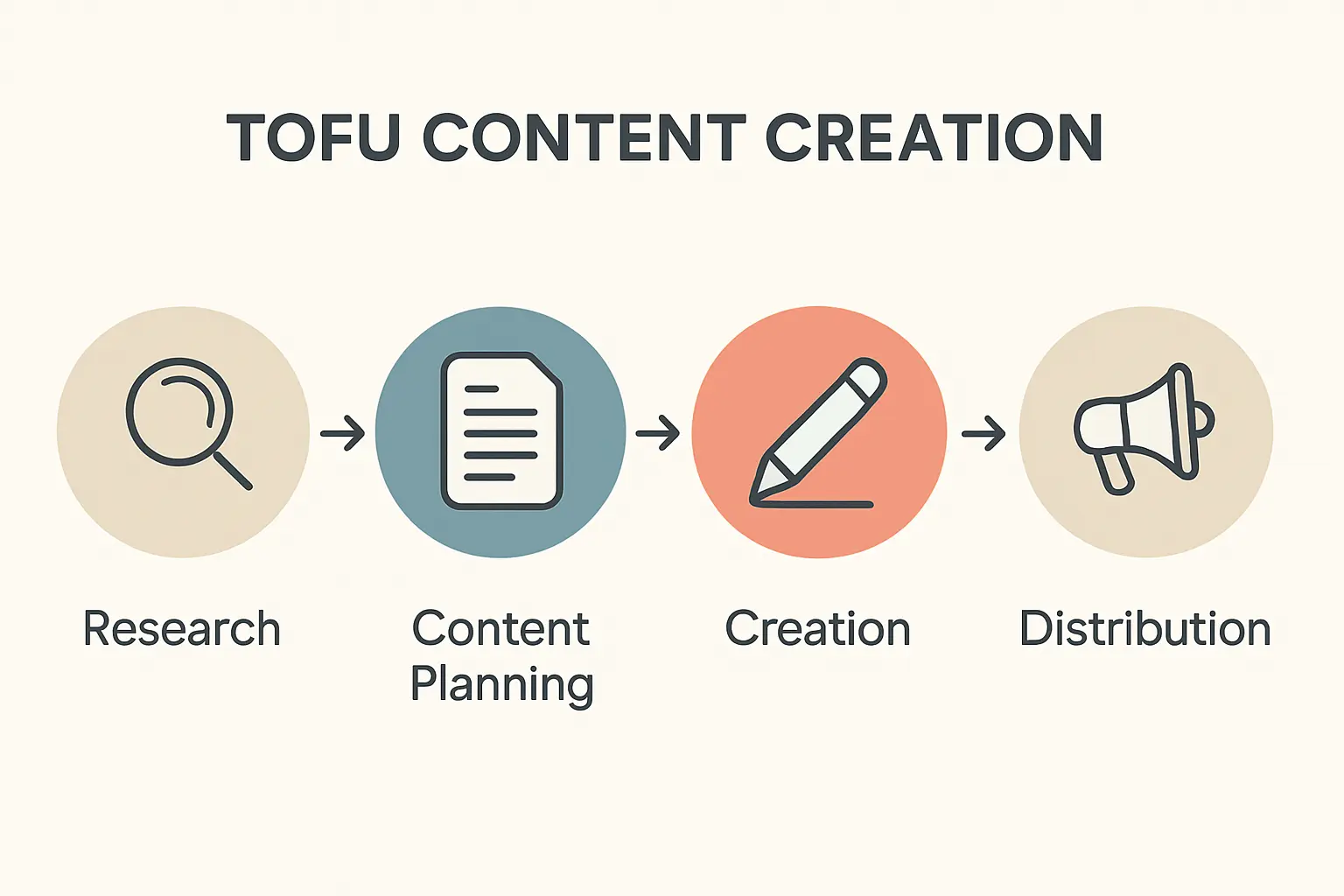

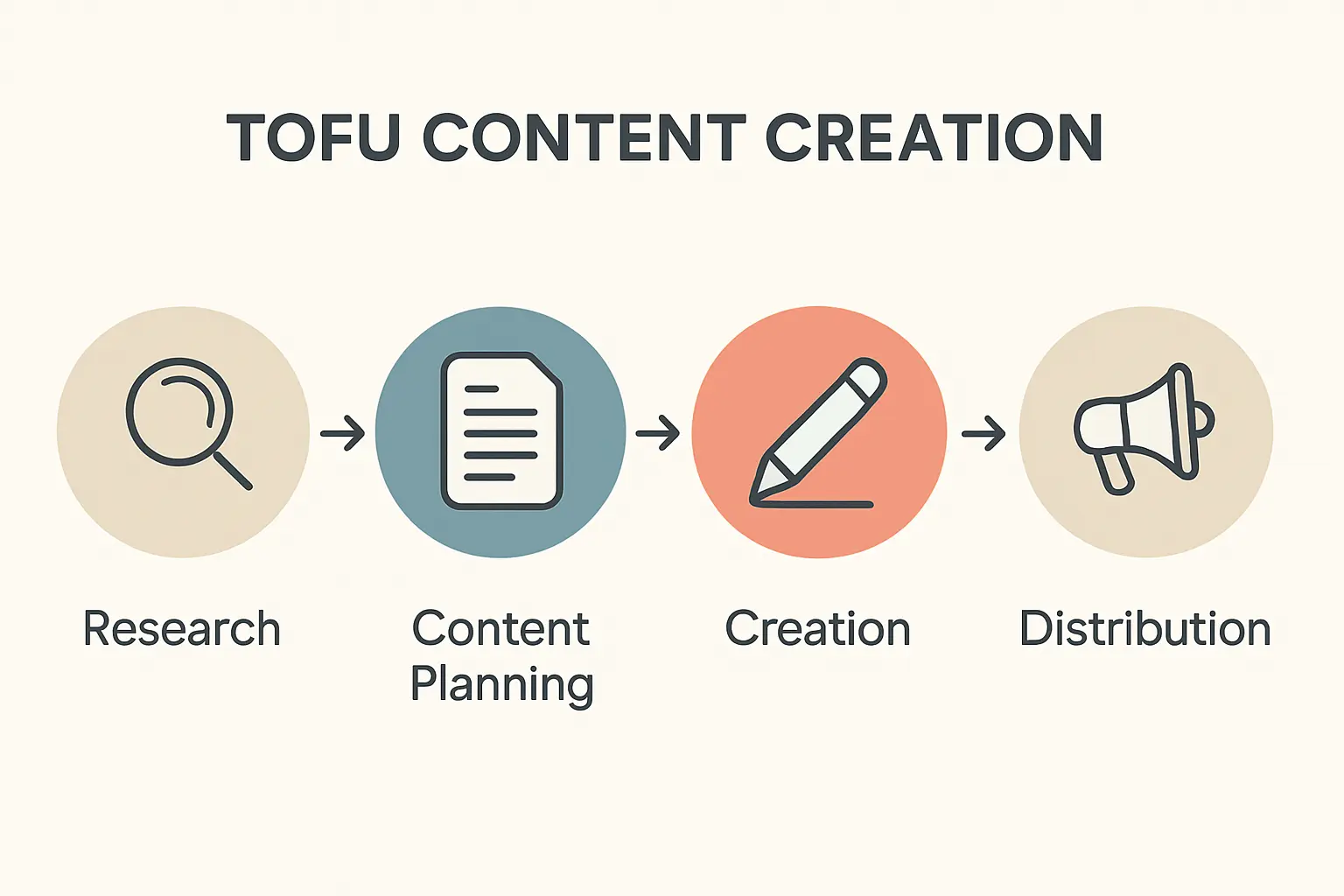

A Three-Phase Framework for Building Your Technical Team

A systematic approach to recruitment, training, and retention ensures that your factory is staffed by a competent and motivated team from day one.

Phase 1: Strategic Recruitment

Rather than searching for non-existent ‘solar experts,’ the recruitment strategy should focus on identifying individuals with the right potential.

-

Collaborate with Technical Institutes: Engage directly with Tunisian universities and vocational CFAs. Present the opportunity to work in a modern, growing industry and establish criteria for identifying top graduates.

-

Look to Adjacent Industries: Actively recruit from sectors known for high standards of quality control and process discipline, such as automotive parts manufacturing or electronics assembly. These individuals already understand the principles of industrial production.

-

Utilize Aptitude Testing: Implement practical tests during the interview process to assess fine motor skills, attention to detail, and the ability to follow complex instructions.

Phase 2: Structured, On-Site Training

This is the most critical phase, where a dedicated training program transforms raw talent into a proficient production force. Based on experience from numerous J.v.G. turnkey projects, a successful program combines theoretical knowledge with extensive hands-on practice.

A comprehensive training curriculum should cover:

-

PV Fundamentals: A classroom-based introduction to how solar cells and modules work.

-

Machine-Specific Operation: Hands-on training for each piece of equipment, from the stringer and laminator to the final testing simulators.

-

Quality Control Checkpoints: Training technicians to be more than machine operators—to act as the first line of defense for quality. This involves learning to identify defects at every stage of production.

-

Safety Protocols: Rigorous instruction on all factory safety procedures to ensure a secure working environment.

A focused, immersive training program can typically bring a new team to operational readiness within four to six weeks.

Phase 3: Cultivating Quality and Retention

Once the line is operational, the focus shifts to continuous improvement and staff retention.

-

Establish a Quality-First Culture: Empower technicians to stop the line if a quality issue is detected. This fosters a sense of ownership and responsibility that is crucial for long-term success.

-

Create Career Pathways: Define clear opportunities for advancement. A talented operator could be promoted to a line leader, quality control inspector, or maintenance technician.

-

Ongoing Skill Development: Provide regular refresher courses and training on new techniques or materials to keep the team’s skills sharp.

For entrepreneurs new to the solar sector, designing and executing such a program can be a complex task. This is precisely where a partner with deep experience in setting up a turnkey solar production line provides immense value. Such a partner can deliver proven training modules and provide experienced engineers on-site to guide the local team through the critical initial production phase.

Frequently Asked Questions (FAQ)

-

How many technicians are needed for a small-scale solar factory?

For a typical semi-automated production line with a capacity of 20–50 MW per year, a workforce of approximately 25–35 employees is required for production and quality control, typically working across two shifts. -

Do all technicians need an engineering degree?

No. While line supervisors or chief engineers will have engineering degrees, most operators and technicians require a technical diploma or relevant vocational training. The most important qualifications are process discipline and attention to detail. -

What is the average time needed to train a new team from scratch?

A well-structured, intensive training program combining classroom theory and hands-on practice can prepare a team for initial production within 4 to 6 weeks. This is often followed by a period of supervised production to solidify skills. -

How does a well-trained team impact the overall investment?

A highly skilled team directly reduces operational risk and protects the initial investment. Higher efficiency, lower material wastage, and superior product quality all contribute to a faster return on investment and a stronger market reputation.

The perceived skilled labor shortage in emerging solar markets like Tunisia is therefore a misconception. The real opportunity lies not in finding ready-made experts, but in implementing a robust system to cultivate local talent.

By viewing the workforce as a strategic asset to develop, an entrepreneur can build a powerful operational advantage, ensuring the long-term success and profitability of their solar manufacturing venture.