Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

Capturing Tunisia’s Solar Market: A Turnkey Factory Investment Blueprint

Many entrepreneurs view solar manufacturing as a global game dominated by large-scale international players. But in markets like Tunisia, national energy strategies are creating a protected and highly lucrative domestic opportunity.

The Tunisian Solar Plan (TSP) is not merely an environmental goal but an industrial policy designed to favor local production for its ambitious infrastructure projects. This creates a unique opening for investors ready to establish a credible, high-quality local manufacturing presence.

This article lays out a blueprint for investors looking to establish a solar module factory tailored to the Tunisian market. It outlines a strategy that leverages a turnkey production setup to meet the demands of government tenders, commercial installations, and agricultural projects—all while building a trusted local brand backed by German engineering standards.

The Tunisian Solar Opportunity: A Market Shaped by Policy

The investment case for a Tunisian solar factory hinges on understanding the national strategy. The government’s clear policy direction provides a predictable pipeline of demand for locally produced modules.

The Tunisian Solar Plan (TSP) and Local Content Requirements

The cornerstone of this opportunity is the Tunisian Solar Plan, which aims to install 3.8 GW of renewable energy capacity by 2030. To put this into perspective, a 50 MW per year factory would need to operate for over 70 years to meet this target alone.

Critically, the government and its state-owned utility, STEG (Société Tunisienne de l’Electricité et du Gaz), often include local content requirements in their public tenders. This means that for large-scale solar farm projects, preference is given to bids using locally manufactured components, including solar modules. This policy effectively creates a captive market for domestic producers who can meet the required quality standards.

Key Demand Segments in Tunisia

The 3.8 GW target is not a single block of demand; it is distributed across several key sectors, each representing a distinct market for a local manufacturer:

-

Government & Utility-Scale Projects: These are the largest projects, directly tendered by STEG. Winning these contracts requires not only competitive pricing but also strict adherence to technical specifications and quality certifications.

-

Commercial & Industrial (C&I) Installations: Businesses across Tunisia are increasingly adopting solar to reduce electricity costs and improve energy security. A local brand can offer faster delivery, local support, and products tailored to regional climate conditions.

-

Agricultural Sector: Modernizing farms and irrigation systems under the TSP relies heavily on solar power, especially in off-grid areas. This creates demand for durable, reliable modules that can withstand harsh environments.

A Four-Phase Blueprint for a Turnkey Solar Factory

A structured approach is essential for entering this market. A turnkey investment model simplifies the process, particularly for entrepreneurs without a background in photovoltaic technology.

Phase 1: Securing Financing and Strategic Partnerships

Before any equipment is ordered, a solid financial and strategic foundation is essential. A comprehensive business plan, supported by credible technical partners, is crucial for securing funding from Tunisian banks or international development finance institutions.

Engaging with local industrial partners or even state-affiliated entities can offer significant advantages. Such partnerships can help navigate the administrative landscape and demonstrate a long-term commitment to the domestic economy, strengthening bids for government tenders.

Phase 2: Navigating Tunisian Energy Regulations

Compliance is not a barrier but a roadmap to market entry. Tunisian regulations for power generation and grid connection are well-defined. A new manufacturing operation must ensure its products meet or exceed these local standards from day one.

This includes obtaining the necessary certifications required to participate in STEG tenders. A knowledgeable technical partner can guide this process, ensuring the factory’s output is immediately eligible for the most valuable projects.

Phase 3: The Turnkey Factory Setup

The physical plant is the core of the investment. A modern, efficient turnkey solar manufacturing line offers the fastest and most reliable path to production. A typical 50 MW facility requires a building of approximately 2,500 square meters and can be fully operational in less than a year.

This setup is designed for efficiency and quality control, enabling a relatively small team of 30-40 employees to produce high-grade solar modules. The focus is on implementing proven, automated processes that guarantee consistent output.

Phase 4: Building a Trusted Local Brand

With a quality product, the focus shifts to market strategy. A successful brand in Tunisia will be built on two pillars: local presence and international quality.

Marketing efforts must be tailored to each key segment. For government tenders, emphasize technical compliance, certifications, and the economic benefits of local production. For commercial and agricultural clients, the message should focus on reliability, local service, and the ‘Made in Tunisia’ label backed by German engineering assurance. This dual approach builds a reputation that resonates across the entire domestic market.

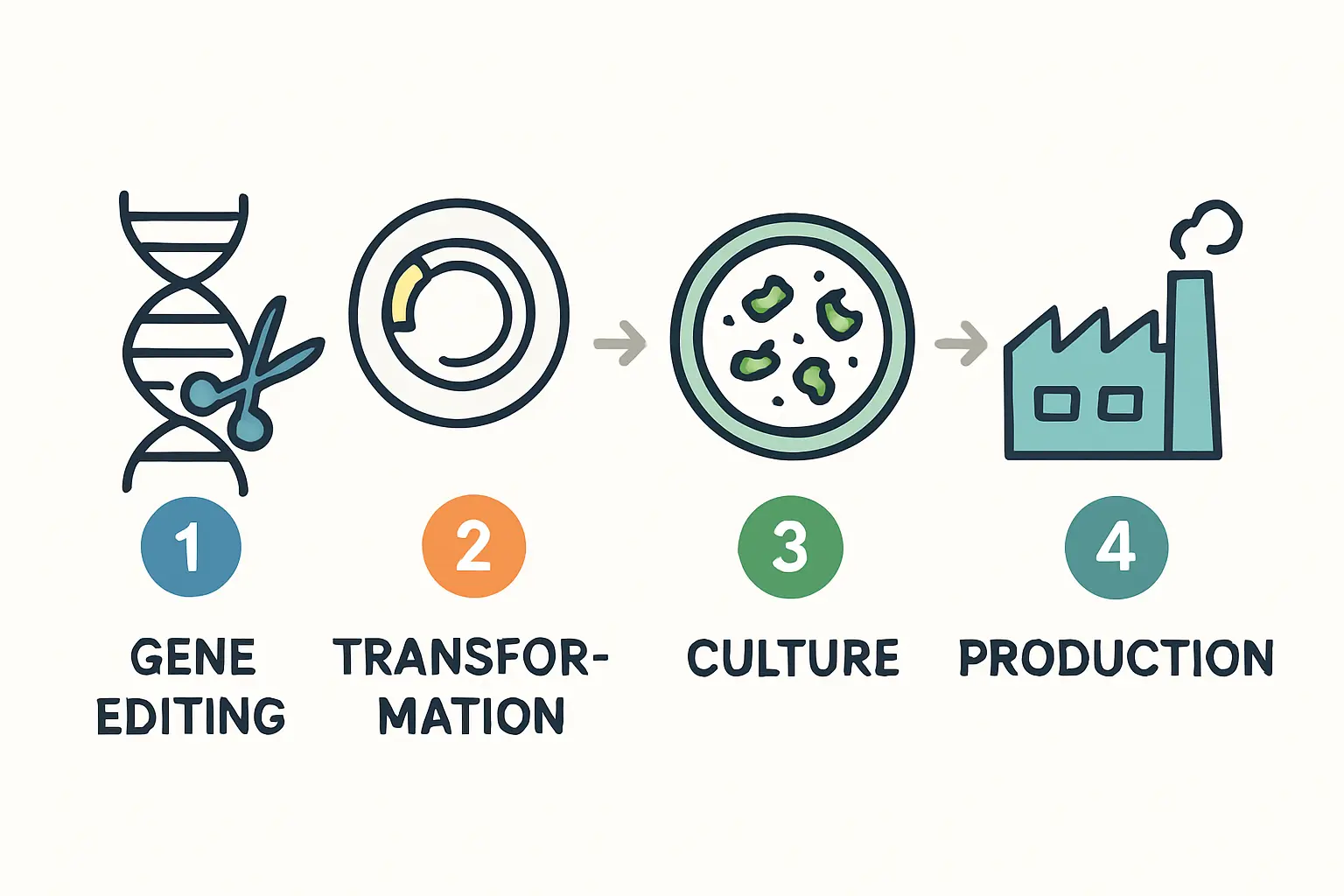

The Role of German Engineering in Ensuring Quality

For a new local brand to win the trust of STEG and private sector buyers, its promise of quality must be demonstrable. This is where integrating German engineering principles into the factory’s operations becomes a critical differentiator.

This is not about importing foreign machinery alone; it is about implementing a complete quality management system. Based on experience gained from European PV manufacturers’ turnkey projects, this involves a meticulous solar module manufacturing process that covers everything from raw material inspection to final performance testing like electroluminescence and ‘sun simulation’. This documented, systematic approach to quality provides the verifiable proof needed to compete for and win high-value contracts, assuring clients that the modules will perform reliably for over 25 years.

Frequently Asked Questions (FAQ)

What is the typical investment for a 50 MW solar factory in Tunisia?

While costs vary with equipment choices and building specifications, an investor should anticipate a budget in the range of €3 to €5 million for a complete turnkey production line and associated setup.

How long does it take for a new factory to become operational?

With a turnkey partner, the timeline from a final investment decision to the first certified module coming off the line is typically between 9 and 12 months.

What are the main challenges when dealing with local regulations?

The primary challenge is not the complexity of the regulations themselves, but the need for precise documentation and adherence to technical standards. Working with a partner experienced in international certifications (like IEC) and their local equivalents is the most effective way to manage this.

Can a non-technical entrepreneur succeed in this industry?

Absolutely. The key message of the pvknowhow.com platform is that an entrepreneur does not need to be a solar expert. A turnkey model provides the pre-configured technology and processes, allowing the business owner to focus on finance, strategy, and market development.

Why is local production so important for government projects in Tunisia?

Local production supports national industrial policy, creates jobs, reduces foreign currency expenditure on imports, and enhances national energy security. For these strategic reasons, government bodies are incentivized to procure locally whenever quality and price are competitive.

Next Steps for Exploration

The Tunisian solar market presents a clear, structured opportunity for investors. The combination of strong government backing, predictable demand, and a preference for local content creates a favorable environment for a new manufacturing enterprise.

Success depends on a well-executed plan that combines local market intelligence with internationally recognized standards of quality and efficiency. For entrepreneurs ready to take the next step, a deeper dive into how to start a solar panel manufacturing business provides a comprehensive overview of the entire journey, from initial concept to full-scale production.

Download: Tunisian Domestic Solar Market Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.