Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The European Union’s push toward energy independence has created a significant opportunity for manufacturers outside its borders yet close enough to serve its markets efficiently. For entrepreneurs and investors, the question is not whether to enter the solar industry but how and where.

While many look to Asia, a more strategic location is emerging: Turkey’s Marmara region, a manufacturing powerhouse positioned at the crossroads of Europe and Asia. This article outlines a comprehensive project plan for establishing a 150 MW TOPCon solar module factory in Turkey to serve the EU market, detailing the location’s strategic advantages, essential technology choices, and the phased implementation of a turnkey project. This blueprint draws on experience gained from European PV manufacturers’ turnkey projects, illustrating a viable path for new entrants into the solar manufacturing sector.

The Strategic Rationale: Why Turkey for EU Solar Module Exports?

The right location is fundamental to the success of any manufacturing venture. Turkey, particularly its Marmara region, offers a compelling mix of logistical, economic, and political advantages for supplying the European solar market.

The EU’s industrial strategy, including the Net-Zero Industry Act, aims to produce 40% of its annual solar deployment needs domestically by 2030. This policy encourages supply chain diversification away from any single region, and Turkish manufacturers are ideally positioned to become a key part of this new, resilient supply chain.

Key advantages include:

-

The EU-Turkey Customs Union: Established in 1995, this agreement eliminates tariffs and trade barriers on most industrial goods, allowing solar modules manufactured in Turkey to enter the EU market without the import duties applied to products from other regions. This provides a significant cost advantage.

-

Geographic Proximity and Advanced Logistics: The Marmara region is home to major ports like Ambarlı and Gemlik, with short, reliable shipping routes to key European hubs such as Rotterdam and Hamburg. This proximity reduces transport times and costs compared to Asian suppliers.

-

Industrial Infrastructure: As Turkey’s industrial heartland, the Marmara region boasts a mature ecosystem of suppliers, a skilled labor force, and the robust infrastructure essential for establishing and operating a sophisticated manufacturing facility.

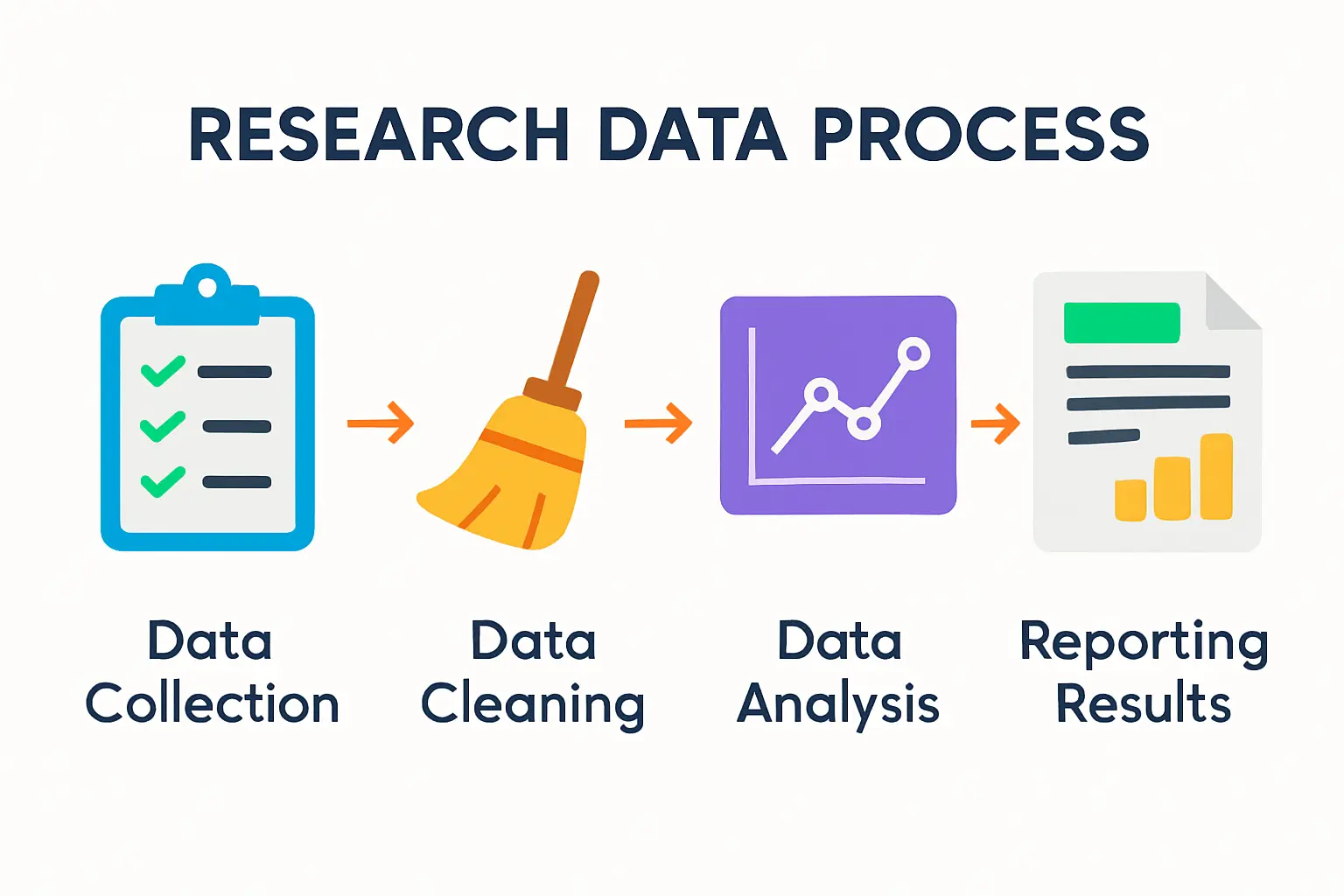

A Turnkey Project Framework: From Concept to Production

A turnkey project approach simplifies the complex process of setting up a solar module factory by consolidating all phases under a single, experienced partner. This model is particularly effective for investors who have strong business acumen but limited expertise in photovoltaic technology.

A typical project timeline spans 12 to 15 months, broken down into distinct phases.

Phase 1: Feasibility and Strategic Planning (Months 1-3)

This initial phase establishes the project’s foundation. It involves detailed site selection within an organized industrial zone in the Marmara region, a thorough financial analysis, and the development of a business plan. Initial discussions with potential EU customers (offtakers) are crucial at this stage to align production with market demand.

Phase 2: Factory Design and Procurement (Months 4-7)

With the strategy defined, the focus shifts to the physical plant. This phase centers on designing the optimal factory layout for a 150 MW production line within an approximately 7,000-square-meter building. Procuring the production line is the most critical step, as a modern, high-efficiency line is essential for producing modules that meet stringent European standards.

Phase 3: Implementation and Commissioning (Months 8-12)

This phase covers the physical factory setup, including any necessary building modifications, utility installation, and production line assembly. Concurrently, recruitment and training begin for the core team of around 110 employees, comprised of 80 production operators and 30 administrative and technical support staff.

Phase 4: Ramp-Up and Certification (Months 12-15)

Once the machinery is commissioned, the factory enters the ramp-up phase. Initial production runs are used to calibrate equipment, optimize processes, and establish rigorous quality control protocols. A critical final step is securing the necessary TÜV and IEC certifications, which are mandatory for selling solar modules in the European Union.

Core Technology: The 150 MW TOPCon DESERT+ Production Line

To compete effectively in the sophisticated EU market, a factory must produce high-performance modules. The choice of technology is therefore paramount. A production line based on Tunnel Oxide Passivated Contact (TOPCon) cell technology is the current industry standard for high efficiency.

TOPCon technology offers several advantages over older technologies like PERC:

-

Higher Efficiency: TOPCon modules can achieve efficiencies exceeding 22.5%, generating more power from the same surface area.

-

Lower Degradation: They exhibit lower power loss over their lifetime, ensuring a better return on investment for the end-user.

-

Superior High-Temperature Performance: This makes them highly effective in sunny climates and also delivers a better overall annual energy yield in temperate European climates.

The selection of the right solar module manufacturing equipment is the most critical decision in this phase. The DESERT+ line specification, developed by EU PV factory turnkey supplier, is engineered to produce robust, high-efficiency modules suitable for diverse and demanding environmental conditions, making them a premium product for the EU market.

Navigating Logistics and Market Access

A successful export strategy extends beyond manufacturing, requiring a deep understanding of EU regulations and logistics. A turnkey solar production line provider often includes support for navigating these complex regulatory landscapes.

Modules exported from Turkey must comply with a range of EU standards, including WEEE for electronics disposal, RoHS for hazardous substances, and increasingly, carbon footprint documentation. The EU’s Carbon Border Adjustment Mechanism (CBAM) will favor products with a transparent and lower carbon footprint, giving Turkish manufacturers a potential edge over imports from regions with less stringent environmental regulations. Establishing clear shipping channels and partnerships with European logistics firms is essential for timely, cost-effective delivery to customers.

Investment and Operational Projections

Understanding the financial scope of such a project is critical for investors. Based on data from similar projects, a 150 MW TOPCon factory represents a significant but manageable investment.

A typical budget allocation is as follows:

-

Total Estimated Investment: Approximately €13.5 million

-

Production Equipment: approximately €9.5 million

-

Building & Infrastructure: approximately €2.5 million

-

Working Capital (Initial): approximately €1.5 million

The operational structure requires a team of approximately 110 personnel to run a two-shift operation in a facility of around 7,000 square meters.

Frequently Asked Questions (FAQ)

Why is TOPCon technology chosen over PERC for a new factory?

TOPCon is the successor to PERC technology, offering higher efficiency and better long-term performance. For a new factory aiming at the competitive EU market, starting with TOPCon ensures the products are future-proof and can command a premium price, maximizing the return on investment.

What are the biggest non-technical challenges in a project like this?

The primary challenges often lie in securing a consistent supply chain for high-quality raw materials (like solar cells and glass) and navigating the complex landscape of EU certifications and import regulations. Building a skilled local management and engineering team is also a critical success factor.

How long does it realistically take for a 150 MW factory to become profitable?

Profitability depends heavily on securing stable offtake agreements with EU buyers and maintaining high operational efficiency. With solid contracts in place, a well-managed factory can typically expect to reach profitability within three to five years of commencing full-scale operations.

What kind of local support is available for investors in Turkey?

Turkey offers a range of investment incentives for strategic projects, which may include tax reductions, land allocation, and social security premium support. Engaging with a local partner or consultant is advisable to navigate the application process and maximize these benefits.

Establishing a 150 MW solar module factory in Turkey is a complex undertaking, yet it represents a strategically sound path to accessing the growing European solar market. With the right technology, a phased turnkey approach, and a clear understanding of the region’s unique advantages, this venture offers a powerful opportunity for entrepreneurs to build a significant presence in the global transition to renewable energy.

For those considering such a venture, the next logical step is to commission a detailed feasibility study and a bankable business plan. This analysis is crucial to validating the project’s potential and defining a clear path to success.

Download: 150 MW TOPCon Solar Module Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.