Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The Middle East and North Africa (MENA) region is home to an estimated 40% of the world’s solar energy potential, yet currently harnesses less than 1% of it. As regional energy demands grow, this gap presents a substantial opportunity for entrepreneurs and investors.

However, launching a solar manufacturing operation in this environment requires more than just capital; it demands a strategic approach to location, technology, and regional trade dynamics.

This article details a complete turnkey project for establishing a 50 MW solar module factory near Mersin, Turkey, showing how a specialized approach can meet the unique demands of MENA markets and transform regional challenges into a competitive advantage.

The Strategic Importance of Location: The Mersin Hub

For any manufacturing venture, logistics are fundamental. The choice of location influences supply chain efficiency, production costs, and access to target markets. Mersin, with one of the largest ports in the Mediterranean, offers a distinct logistical advantage for a solar factory targeting the MENA region.

Positioned at the crossroads of Europe, Asia, and Africa, a facility in Mersin can efficiently receive raw materials and export finished solar modules to key markets across North Africa and the Middle East. This strategic positioning minimizes shipping times and costs, directly impacting the financial viability of the operation.

A factory here isn’t just a production site—it’s a distribution hub engineered for regional dominance.

Technology Designed for Arid Climates: The Glass-Glass Advantage

Standard solar modules, typically designed for moderate European climates, often underperform in the harsh conditions of the MENA region. High ambient temperatures, abrasive sandstorms, and intense UV radiation can accelerate the degradation of conventional materials like plastic backsheets, leading to a significant loss in performance and a shorter operational lifespan.

These challenges demand a technology specifically engineered for desert environments. The solution lies in bifacial glass-glass modules. Unlike standard modules that use a polymer backsheet, these modules encase the solar cells between two layers of heat-strengthened glass.

This construction offers several critical benefits for the MENA region:

-

Enhanced Durability: The glass-glass structure provides superior protection against sand abrasion and moisture ingress, significantly extending the module’s lifetime.

-

Higher Temperature Resistance: Glass is more stable at high temperatures, reducing the performance degradation common in hot climates.

-

Increased Energy Yield: As the name suggests, bifacial modules capture sunlight on both sides. When light reflects off the ground (a common occurrence on sandy or light-colored surfaces), the rear side of the module generates additional power. This can increase the total energy yield by up to 25%.

Expert-led European solar project architecture and modeling firm has refined this glass-glass technology under its DESERT+ specification, creating a product ideally suited to maximize energy production and longevity in these demanding solar environments.

Navigating Regional Commerce and Trade Agreements

Establishing a manufacturing presence to serve multiple countries involves navigating a complex web of trade agreements. For the MENA region, key frameworks include the Greater Arab Free Trade Area (GAFTA), the Pan-Arab Free Trade Area (PAFTA), and the Agadir Agreement.

Understanding the rules of origin, customs duties, and certification requirements of each agreement is critical for ensuring products can move freely and competitively across borders. Misinterpreting these regulations can lead to costly delays, tariffs, or even denial of market access.

For this reason, expert consulting based on decades of international project experience is integral to any successful setup. For instance, experienced European turnkey engineering team, have provided guidance to numerous clients on structuring their operations to leverage these agreements effectively, turning a potential bureaucratic hurdle into a strategic tool for market entry.

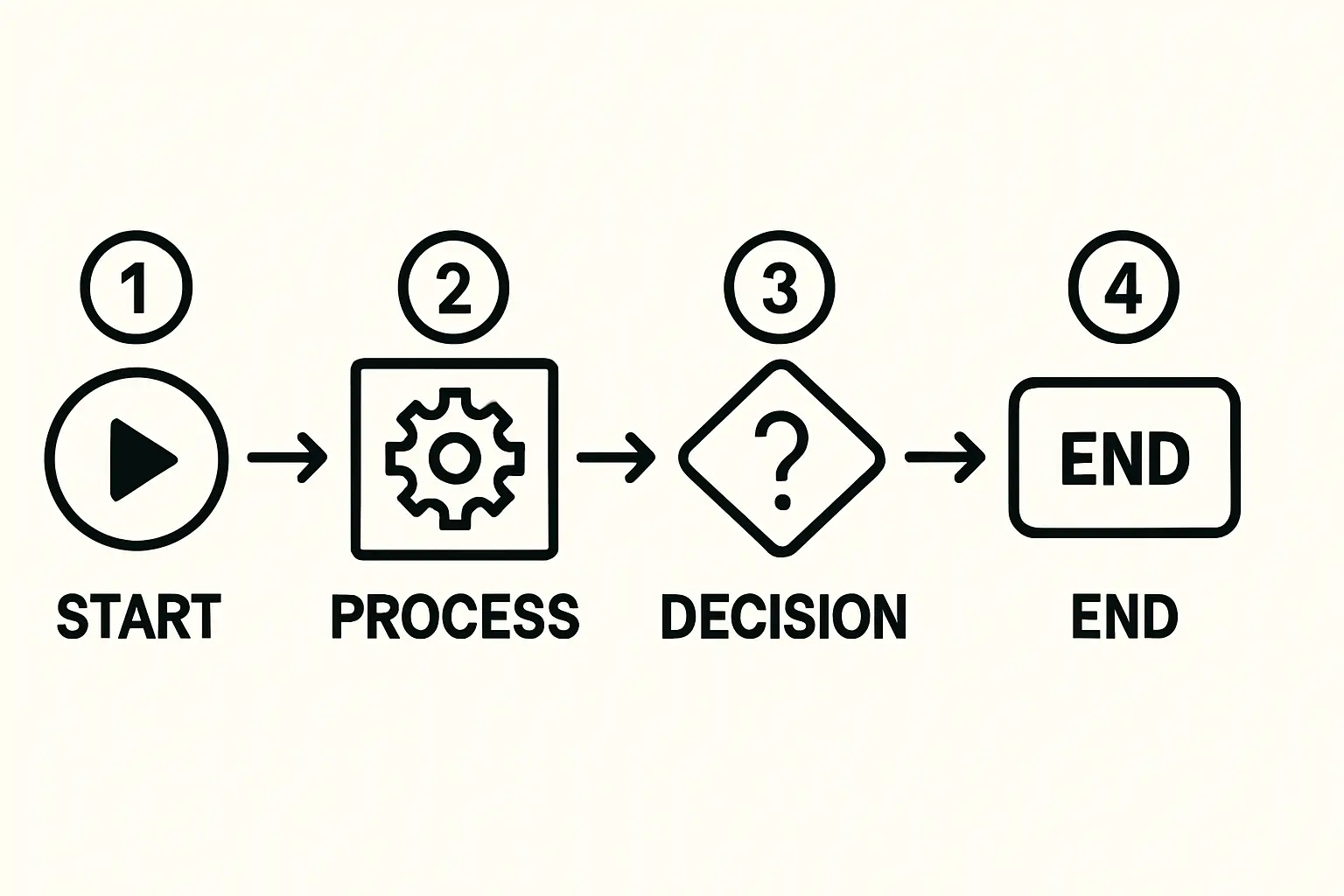

The Turnkey Project Blueprint: A 12-Month Path to Production

A turnkey solar module production line provides a structured, end-to-end solution for investors entering the market. It encompasses everything from factory layout and machine procurement to staff training and process optimization.

A typical 50 MW bifacial glass-glass facility based on this model involves:

-

Initial Capacity: 50 megawatts per year, scalable for future growth.

-

Workforce: A lean, efficient team of approximately 30 employees.

-

Timeline: From initial planning to full production in less than 12 months.

This structured approach de-risks the entry process, particularly for entrepreneurs who have business acumen but are not experts in photovoltaic engineering. It provides a clear, predictable path from investment decision to revenue generation.

Frequently Asked Questions (FAQ)

-

What does ‘turnkey project’ mean in this context?

A turnkey project means a single provider, like an EU-based photovoltaic manufacturing solution partner, manages all aspects of setting up the factory. This includes designing the layout, supplying and installing all machinery, training the local staff, and establishing quality control processes, ultimately handing over a fully operational facility to the owner. -

Why is bifacial glass-glass technology essential for the MENA region?

Its dual-glass construction makes it highly resistant to the region’s specific challenges: sand abrasion, high temperatures, and humidity. In addition, its ability to capture reflected light from the ground significantly increases energy output in desert environments, delivering a better return on investment. -

What is the typical investment required for a 50 MW factory?

The investment required varies based on the level of automation and specific machinery choices. A detailed financial model is a key component of the initial planning phase. -

Do I need a technical background to own and operate such a factory?

No. The turnkey model is designed specifically for business professionals and investors who are not solar experts. The provider supplies the technical expertise, training, and operational frameworks, allowing the owner to focus on business management and strategy.

Next Steps in Your Journey

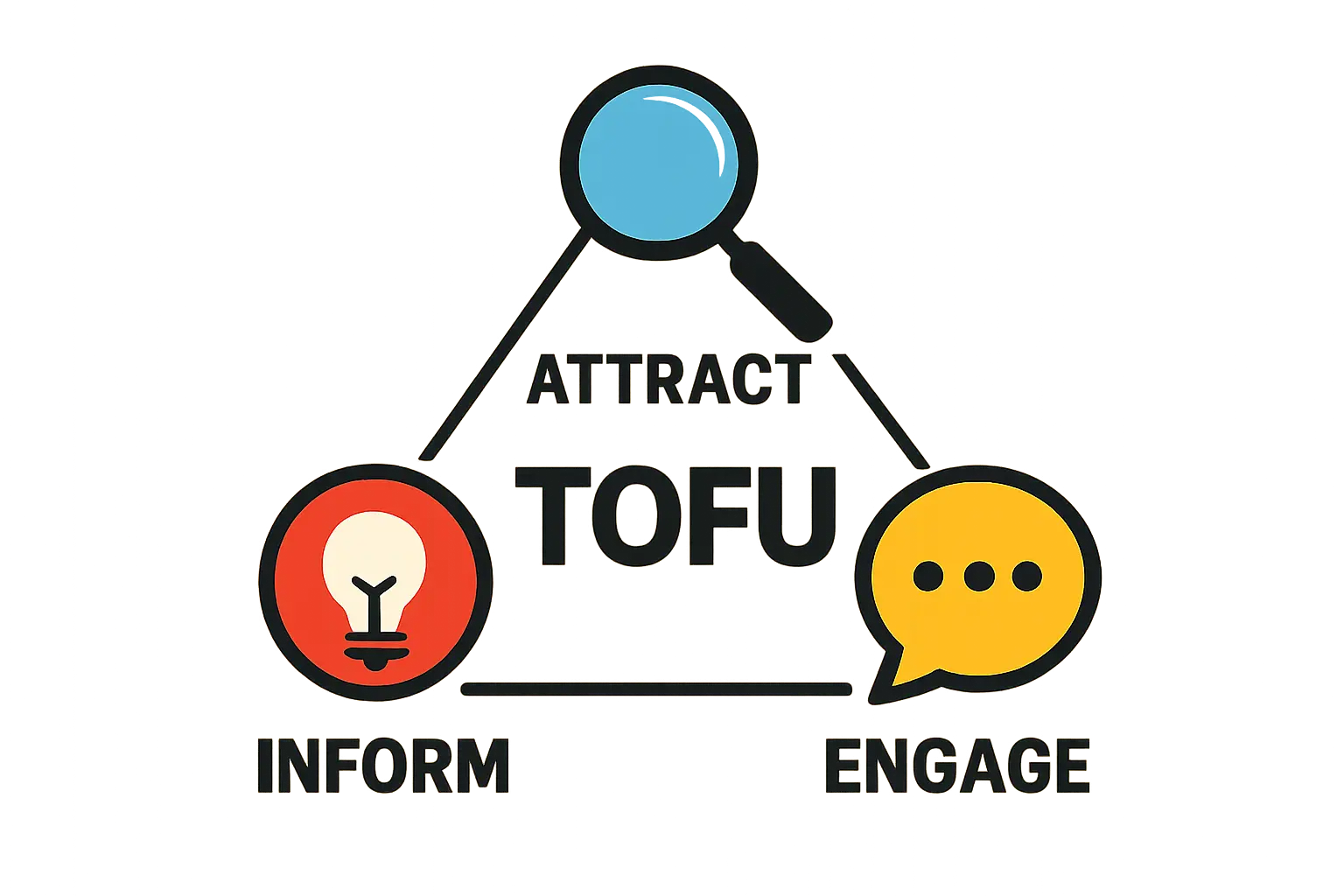

This case study showcases a viable, strategic model for entering the MENA solar manufacturing market. The combination of a prime logistical location, climate-appropriate technology, and expert guidance on trade creates a powerful formula for success.

The foundation of any such venture is a robust and bankable business plan. A comprehensive plan should detail market analysis, technological choices, financial projections, and operational strategy to secure financing and guide decision-making. With the right preparation and partners, the immense solar potential of the MENA region is well within reach for the forward-thinking investor.

Download the 50 MW Bifacial Module Factory Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.