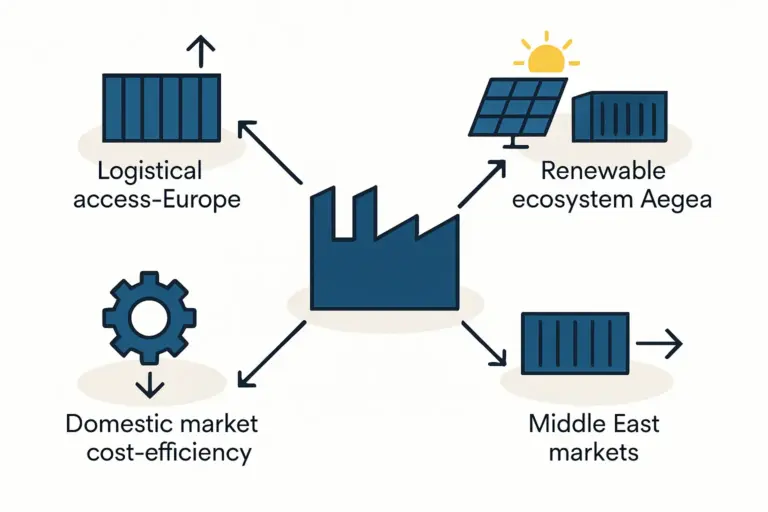

An international investor eyeing the Turkish solar market sees immense potential: high solar irradiation, growing energy demand, and strong government support. The business plan is solid, the technology selected, and the financing viable.

Yet, a crucial factor often overlooked in the initial stages can determine a project’s profitability: a local regulation known as the Yerli Malı Belgesi, or Domestic Goods Certificate.

This certificate is not merely administrative paperwork. It’s the key that unlocks preferential government tariffs and incentives, capable of transforming a standard solar manufacturing venture into a highly profitable one. For any entrepreneur considering a solar module production line, understanding this requirement is fundamental to success in the Turkish market.

Understanding the ‘Yerli Malı Belgesi’: A Strategic Advantage

The ‘Yerli Malı Belgesi’ is a certificate issued by Turkish authorities to verify that a product has been manufactured with a significant proportion of local content. The policy’s goal is to bolster the national economy, encourage domestic manufacturing, and reduce reliance on imports.

For a solar module manufacturer, obtaining this certificate provides a critical competitive edge. Certified “domestic” modules are eligible for higher feed-in tariffs under the Renewable Energy Resources Support Mechanism (YEKDEM).

Solar power plants using these modules can sell electricity to the grid at a premium price, making them far more attractive investments. As a result, developers of large-scale solar projects prioritize and will often pay a premium for modules that carry the ‘Yerli Malı’ certification.

The Core Requirement: Achieving the Domestic Contribution Rate

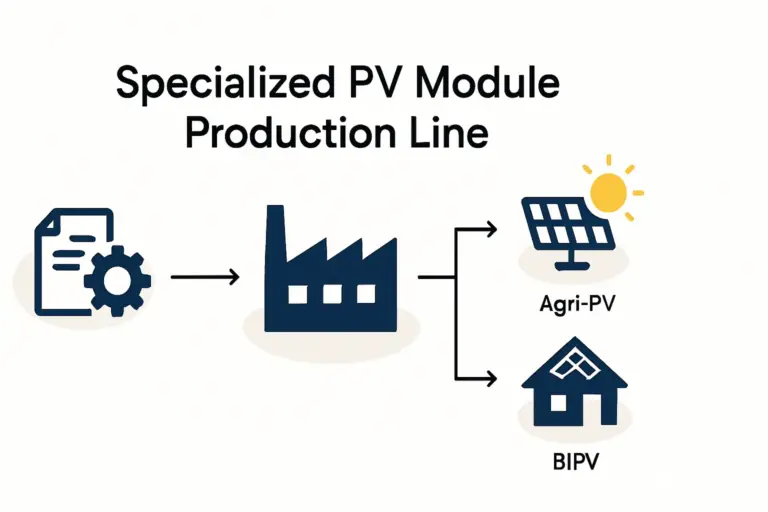

The central requirement for certification is proving that at least 55% of the solar module’s components and associated costs are of Turkish origin. This is not, however, a simple calculation based on the purchase price of materials.

The Turkish Ministry of Industry and Technology has established a specific framework that assigns a percentage value to each component and manufacturing step. To achieve certification, the combined percentage value of the locally sourced components and manufacturing processes must meet or exceed this threshold.

A typical breakdown includes contributions from:

- Solar Cells: The single most significant component, often representing the largest percentage contribution. Sourcing cells locally is a major step toward compliance.

- Solar Glass: A key structural component.

- Aluminum Frame: The module’s exterior structure.

- Junction Box and Diodes: The electrical interface of the module.

- Encapsulant (EVA/POE) and Backsheet: Materials used to laminate and protect the cells.

- Labor and General Factory Expenses: The value of local labor and operational costs also contributes to the total.

This system requires a strategic approach. A manufacturer must carefully analyze the local supply chain and decide which components to source domestically to reach the 55% target—a decision that directly impacts the factory’s setup and the required machinery.

A Step-by-Step Guide to the Certification Process

The certification process is systematic and requires meticulous preparation. Based on experience from J.v.G. turnkey projects, it generally follows four main stages.

1. Strategic Planning and Supplier Qualification

This phase begins long before production starts. Within your solar manufacturing business plan, you must identify and vet potential local suppliers for every component you intend to source within Turkey. Establishing relationships with reliable, high-quality local partners is critical. Due diligence must confirm their production capacity, quality standards, and their own ‘Yerli Malı’ compliance for the goods they supply.

2. Documentation and Application

Once the production facility is operational, you can submit the formal application, typically to the local Chamber of Commerce or directly to the Turkish Standards Institution (TSE). The application dossier is extensive and must include:

- Company registration documents.

- A detailed production flowchart.

- A capacity report for the manufacturing line.

- Invoices and certificates of origin for all locally sourced materials.

- A formal declaration of the domestic contribution ratio calculation.

3. The On-Site Audit

After reviewing the application, auditors from the designated institution will conduct an on-site inspection of the factory. During this audit, they will:

- Verify that the production process matches the submitted documents.

- Inspect raw material storage to confirm the origin of components.

- Observe the machinery in operation.

- Review production records and quality control procedures.

A well-organized factory with clear and traceable documentation is essential for a successful audit.

4. Issuance and Renewal

If the audit is successful and all documentation is in order, the ‘Yerli Malı Belgesi’ is issued. The certificate is typically valid for one year and must be renewed annually through a similar review and potential re-audit to ensure ongoing compliance.

Common Challenges for New Entrants

While the process is straightforward on paper, international investors often encounter several common challenges:

- Local Supply Chain Reliability: The quality and availability of some components from local suppliers can be inconsistent. Securing a stable supply of high-performance, locally manufactured solar cells is often the most significant hurdle.

- Documentation Complexity: The administrative requirements can be demanding, particularly for those unfamiliar with Turkish commercial regulations. Minor errors or omissions in the paperwork can lead to significant delays.

- Balancing Cost and Compliance: Sourcing a component locally can sometimes be more expensive than importing it. The manufacturer must perform a careful cost-benefit analysis, weighing the higher component cost against the substantial long-term revenue gains from the feed-in tariff premium. This strategic trade-off is a core component of building a turnkey solar factory in Turkey.

Frequently Asked Questions (FAQ)

What is the primary benefit of obtaining the ‘Yerli Malı’ certificate?

The primary benefit is financial. Solar power plants using certified domestic modules qualify for a significantly higher, government-guaranteed price (feed-in tariff) for the electricity they generate, making your modules more valuable to project developers.

Can a company fully owned by foreign investors obtain this certificate?

Yes. The ownership structure of the company is not the deciding factor. The key is that the manufacturing takes place within Turkey and the final product meets the 55% domestic content threshold as defined by the regulations.

How long does the initial certification process typically take?

Once the factory is operational and all documentation is prepared, the process from application to issuance usually takes two to four months. However, the preparatory phase of qualifying suppliers should begin much earlier.

What happens if a manufacturer does not meet the 55% threshold?

The manufacturer can still produce and sell solar modules in Turkey and for export. However, their products will not be eligible for the preferential YEKDEM tariffs, placing them at a significant price disadvantage for large-scale domestic projects.

Is it necessary to source every single component locally?

No. The goal is to reach a cumulative value of at least 55% based on the government’s pre-defined contribution list. A typical strategy involves sourcing the highest-value components locally, such as cells and glass, while potentially importing others where a local option is not feasible or cost-effective.

Conclusion: Your Path Forward

For entrepreneurs and investors looking to enter the Turkish solar manufacturing sector, the ‘Yerli Malı’ regulation is not a bureaucratic obstacle but a strategic framework for success—one that requires a diligent and forward-thinking approach.

Success depends on integrating domestic content compliance into the business plan from the very beginning, as it influences the choice of machinery, factory layout, supply chain development, and the overall financial model.

For professionals without a deep background in photovoltaic production, navigating these regulatory nuances can be a significant challenge. Structured guidance and expert support can de-risk this process, ensuring a factory is designed for both compliance and profitability from day one.