Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For international entrepreneurs, the United Arab Emirates holds immense potential. Government initiatives like the UAE Net Zero 2050 strategy are driving unprecedented demand for renewable energy, creating a prime opportunity for local solar module manufacturing. However, entering a new market, especially one with a distinct business culture and regulatory framework, presents significant challenges. The challenge isn’t the opportunity itself, but how to access it effectively and securely.

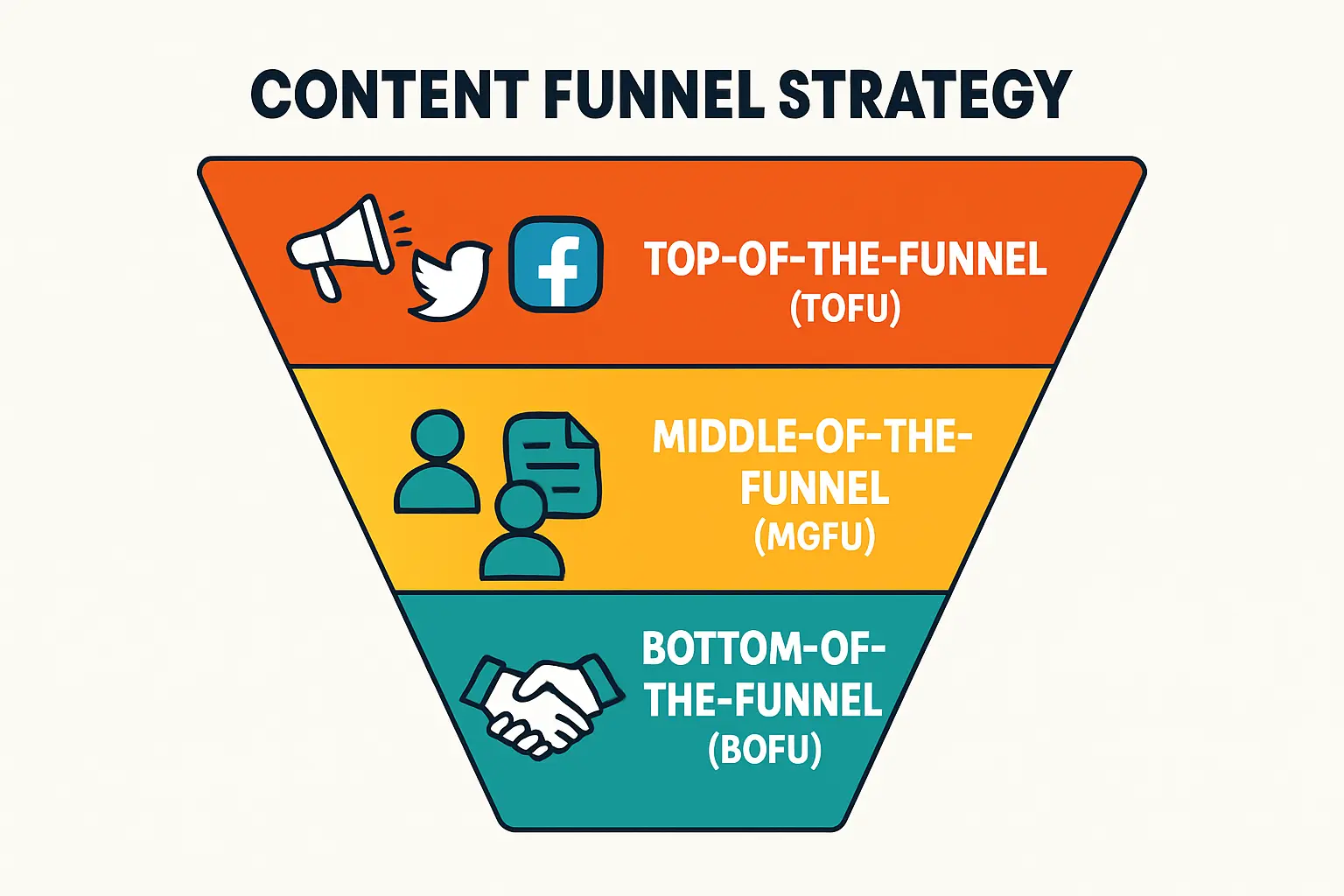

For many successful international investors, the answer lies in a Joint Venture (JV) with a local Emirati sponsor. This model is far more than a legal formality; it is a strategic partnership combining foreign capital and vision with invaluable local market access and influence. This guide outlines how to structure such a partnership—from navigating legal frameworks to implementing the technical production line—to ensure all parties are aligned for success.

Understanding the UAE’s Strategic Position in Solar Manufacturing

The UAE’s commitment to diversifying its economy beyond oil and gas has positioned it as a global hub for clean energy. This is not just a policy statement but a well-funded national priority, creating a stable and highly attractive environment for investment in solar manufacturing.

Key drivers include:

-

National Energy Goals: The Dubai Clean Energy Strategy 2050 aims to generate 75% of the emirate’s power from clean sources, requiring a massive and sustained supply of high-quality solar modules.

-

Economic Incentives: The UAE offers significant advantages, including zero income tax for corporations and individuals, creating a highly favorable financial environment for new enterprises.

-

Geographic Hub: Situated at the crossroads of Europe, Asia, and Africa, the UAE provides unparalleled logistical access to rapidly growing solar markets across the MENA region and beyond. Its world-class port infrastructure, like Jebel Ali, streamlines the import of raw materials and the export of finished goods.

This government-backed push creates reliable, long-term demand for locally produced solar modules, reducing the market risk for new manufacturers.

The Joint Venture Model with an Emirati Sponsor: A Framework for Success

A Joint Venture in the UAE involves a formal agreement between a foreign investor and a local partner to establish a new business entity. Executed correctly, this structure becomes a powerful vehicle for mitigating risk and accelerating growth.

The Role of the Local Sponsor

An effective Emirati sponsor is far more than a silent partner merely fulfilling a legal requirement. A strategic local partner provides critical advantages that an outside investor cannot easily replicate:

-

Navigating Bureaucracy: Deep knowledge of local administrative processes, from business registration and licensing to securing permits and environmental clearances.

-

Market Access: The ability to facilitate introductions to key decision-makers, government entities, and major local buyers—often essential for securing large-scale projects and tenders.

-

Cultural Insight: An understanding that helps bridge cultural gaps in business negotiations and management practices, ensuring smoother operations.

Legal Structures and Ownership

The most common legal vehicle for a JV on the UAE mainland is a Limited Liability Company (LLC). While foreign ownership laws have evolved to permit 100% foreign ownership for many activities, a partnership structure remains strategically compelling.

For a manufacturing enterprise, establishing a strong local foundation is critical. A JV where the Emirati sponsor holds a 51% stake can provide preferential treatment in government procurement and offer a more stable platform for navigating the local business landscape. The initial structuring of this partnership is a critical step. A comprehensive solar panel manufacturing business plan is essential to define the roles, responsibilities, and financial projections for all partners from the outset.

Structuring Profit-Sharing and Management Control

A key concern for any international investor is maintaining operational control and ensuring a fair return on their investment. A common misconception is that a 51% local ownership stake automatically dictates a corresponding 51% share of profits or complete control.

The division of profits, management responsibilities, and operational control are defined in the company’s Memorandum of Association (MOA). This legally binding document can be structured to protect the foreign investor’s interests by:

-

Allocating profits in a proportion different from the shareholding (e.g., 80% to the foreign investor).

-

Granting the foreign partner full management authority over the factory’s daily operations.

-

Defining clear decision-making processes and outlining the responsibilities of each partner.

Navigating the Technical Implementation with a Neutral Partner

While the JV structure solves market access and legal challenges, a critical gap often remains: technical expertise. The foreign investor provides the capital and the local sponsor brings the connections, but neither typically possesses the specialized engineering knowledge to design, build, and operate a state-of-the-art solar module factory.

The Role of the Turnkey Technology Partner

This is where a neutral, third-party technology partner becomes essential. A firm like an EU-based photovoltaic manufacturing solutions partner acts as the project’s technical guarantor, aligning the interests of both the investor and the sponsor. Drawing on experience from its turnkey projects, the EU PV factory turnkey supplier ensures all decisions related to machinery, process, and quality control are based on sound engineering principles, free from conflicts of interest. The technology partner is responsible for the complete technical execution, from factory layout planning to the final acceptance test.

Implementing a DESERT+ Production Line

Manufacturing solar modules for the UAE and surrounding regions requires a specialized approach. The extreme environmental conditions—high ambient temperatures, intense UV radiation, and abrasive sand—demand modules built to a higher standard.

A DESERT+ production line is specifically engineered to manufacture modules that can withstand these harsh conditions. This involves:

-

Optimized Bill of Materials (BOM): Selecting materials like specialized encapsulants and backsheets that resist heat and UV degradation.

-

Advanced Cell Technology: Integrating high-efficiency cells like TOPCon or HJT that perform better in high-temperature conditions.

-

Robust Manufacturing Processes: Ensuring superior lamination and junction box sealing to prevent moisture and dust ingress.

Setting up a turnkey solar production line designed for these specifications ensures the final product is reliable, durable, and can command a premium in a market where quality is paramount.

Common Challenges and Strategic Considerations

Even with a well-structured JV, entrepreneurs should remain aware of potential challenges.

-

Cultural Alignment: Clear and continuous communication is vital to ensure both partners’ business expectations and management styles are aligned.

-

Regulatory Navigation: While a local partner is an invaluable asset, the foreign investor must maintain a working knowledge of the UAE’s commercial and labor laws.

-

Supply Chain Logistics: Sourcing raw materials is crucial. Although the UAE’s logistics are excellent, establishing reliable supply chains for solar cells, glass, and other components requires careful planning.

Success in this venture ultimately relies on the careful integration of strategic partnership, legal diligence, and technical excellence.

Frequently Asked Questions (FAQ)

What is the typical initial investment for a solar factory in the UAE?

For a modern, semi-automated production line with an annual capacity of 50–100 MW, the initial investment in machinery and setup is typically between 3 and 5 million USD. This does not include the cost of the building or working capital.

How does a JV in a Free Zone differ from a Mainland setup?

A Free Zone company allows for 100% foreign ownership and is ideal for businesses focused purely on export. A Mainland LLC, typically structured as a JV, is often better suited for selling directly into the UAE domestic market and participating in government tenders.

Can the foreign investor have full management control with less than 50% ownership?

Yes. Management control, profit distribution, and operational authority are defined in the company’s Memorandum of Association (MOA), not by the shareholding percentage alone. A well-drafted MOA can grant the foreign partner full control over the business operations.

How long does it take to set up a production line from planning to operation?

With a clear plan and an experienced turnkey partner, a solar module production line can be fully operational in approximately 9 to 12 months. This includes factory planning, machine procurement, installation, commissioning, and staff training.

Why is a specialized ‘DESERT+’ line necessary for the UAE market?

Standard solar modules lose efficiency significantly in high heat and can degrade quickly due to intense UV radiation and sand abrasion. A DESERT+ line uses specific materials and manufacturing processes to produce robust modules that maintain high performance and have a longer lifespan in harsh desert climates.

Conclusion: A Strategic Path to Market Entry

The Joint Venture model with a local Emirati sponsor offers a structured, de-risked pathway for international entrepreneurs to enter the lucrative UAE solar manufacturing market. Combining foreign investment, local market expertise, and proven German engineering from a neutral technology partner, this tripartite structure creates a formidable enterprise. It aligns financial, strategic, and technical interests, paving the way for a profitable and sustainable business venture.

For investors ready to explore this opportunity, the next logical step is to conduct detailed feasibility studies and financial modeling to build a robust business case.

Download the UAE Solar Joint Venture Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.