Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

The United Arab Emirates, and Dubai in particular, is a globally recognized hub for commerce and logistics. For entrepreneurs, this strategic position opens up opportunities that extend far beyond trade into high-tech manufacturing.

Establishing a solar module production facility within the Jebel Ali Free Zone (JAFZA) provides a unique launchpad into one of the world’s fastest-growing renewable energy markets: the Middle East and North Africa (MENA) region.

This analysis outlines a comprehensive investment scenario for a 200 MW export-focused solar module factory. We explore the strategic advantages of JAFZA, the technical requirements for producing specialized ‘DESERT+’ modules, and a practical framework for financing and market entry based on a turnkey implementation model from engineering firms like European industrial solutions provider.

The Strategic Rationale: Why JAFZA is a Prime Location for Solar Manufacturing

An investor’s choice of location is one of their most critical decisions. JAFZA presents a compelling business case built on three core advantages: unparalleled logistics, a supportive regulatory environment, and strong alignment with national strategic goals.

-

Logistical Supremacy: JAFZA is home to the Port of Jebel Ali, one of the world’s largest container ports. This provides direct, cost-effective access to global supply chains for raw materials and efficient sea-freight routes for exporting finished modules across the MENA region and beyond. Its proximity to Al Maktoum International Airport also strengthens air cargo capabilities for time-sensitive components.

-

Favorable Business Environment: As a free zone, JAFZA offers significant financial incentives, including 100% foreign ownership, zero corporate taxes, and no customs duties on imports or re-exports. This framework simplifies business operations and substantially improves the financial viability of an export-oriented manufacturing venture.

-

Alignment with UAE’s Energy Strategy 2050: The UAE’s commitment to achieving Net Zero by 2050 is driving massive investment in renewable energy. By establishing local production, a new manufacturer contributes directly to this national vision, creating opportunities for preferential treatment in government tenders and building a strong local brand identity.

Analyzing the MENA Market Opportunity

Demand for solar energy in the MENA region is expanding rapidly. Projections indicate that regional investments in solar power are set to exceed USD 20 billion by 2025. This growth is driven by national decarbonization goals, falling solar technology costs, and an urgent need for energy security.

Many regional projects, however, still rely on imported modules from Asia, introducing supply chain vulnerabilities and logistical delays. A factory in JAFZA is perfectly positioned to address this gap. It can offer regional customers:

- Reduced shipping times and costs.

- Modules specifically engineered for the local climate.

- Greater supply chain resilience and transparency.

By manufacturing in the region, for the region, an enterprise can gain a significant competitive advantage. A sound financial plan starts with understanding the full scope of capital required, which makes it crucial to review the typical investment requirements for a solar module factory.

Defining the Product: The ‘DESERT+’ Module Specification

The MENA region’s climate presents unique challenges for solar technology. Extreme heat, high UV radiation, and abrasive sand demand modules that are far more durable than standard products. A successful manufacturing strategy hinges on producing a specialized ‘DESERT+’ module with specific technical attributes.

Key Features of a DESERT+ Module:

-

High-Temperature Performance: Uses cells with a low temperature coefficient to minimize power loss in ambient temperatures that regularly exceed 45°C.

-

Bifacial Technology: This technology enables modules to capture sunlight on both sides. The rear side absorbs light reflected from the ground (albedo)—a feature particularly effective over sandy or light-colored surfaces that can increase energy yield by up to 15%.

-

Durable Encapsulation: Employs advanced materials like POE (Polyolefin Elastomer) instead of standard EVA (Ethylene Vinyl Acetate) to prevent degradation from heat and humidity.

-

Robust Framing: A reinforced frame design to withstand high wind loads and the logistical demands of transport to remote project sites.

Producing a premium, climate-specific module allows a new manufacturer to compete on quality and performance rather than price alone, commanding higher margins and building a reputation for reliability.

A Blueprint for a 200 MW Production Facility

A 200 MW annual capacity strikes a strong balance between economies of scale and a manageable initial investment. Such a facility can be established efficiently using a structured, turnkey approach.

Facility and Investment

A 200 MW facility typically requires a factory floor space of 8,000 to 10,000 square meters. The total capital expenditure for equipment, installation, and commissioning generally falls in the range of USD 15–20 million. This investment covers all core machinery, from cell stringing and lamination to framing and final testing. Experienced engineers suggest that a phased approach to reaching full capacity can optimize cash flow during the initial years of operation.

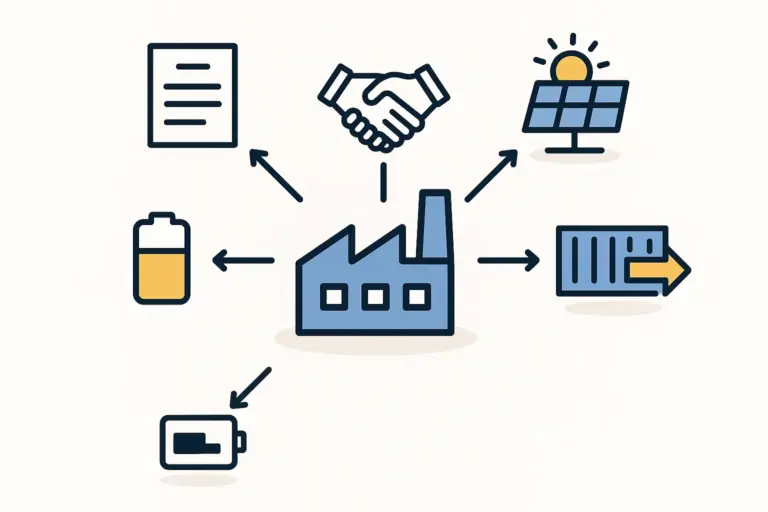

Turnkey Implementation with European Solar PV Equipment Provider

For entrepreneurs without a background in solar engineering, a turnkey solution de-risks the entire process. A turnkey solar module production line partner like EU PV factory turnkey supplier manages every step of the project, from concept to completion. This service typically includes:

-

Line Design and Layout: Optimizing the factory floor for efficient material flow.

-

Equipment Sourcing and Integration: Selecting and procuring machinery from leading global suppliers.

-

Installation and Commissioning: On-site management of the entire setup process.

-

Staff Training and Knowledge Transfer: Equipping the local workforce with the skills to operate and maintain the production line.

This guided approach ensures the facility is built to international standards and becomes operational on a predictable timeline.

Navigating Regulatory and Operational Hurdles

While the opportunity is significant, any new manufacturing venture must navigate several practical challenges.

-

JAFZA Registration and Compliance: The process involves establishing a Free Zone Establishment (FZE) and obtaining the necessary industrial licenses. Although JAFZA’s processes are streamlined, professional guidance is recommended to ensure complete compliance.

-

Supply Chain Management: A turnkey partner can assist in establishing reliable supply chains for critical raw materials such as solar cells, glass, and aluminum frames.

-

Certification and Quality Assurance: To export modules across the MENA region and beyond, obtaining certifications from bodies like TÜV Rheinland (IEC 61215, IEC 61730) is essential. A robust quality management system must be integrated into the production process from day one.

Financial Modeling and Go-to-Market Strategy

A sound financial plan will likely involve a blended approach, combining owner’s equity with debt financing from local or international banks. Securing this financing hinges on a detailed business plan supported by feasibility studies from an experienced consultant.

The go-to-market strategy should be phased:

-

Phase 1 (Year 1): Focus on establishing a foothold in the UAE market, targeting utility-scale projects and commercial rooftop installations.

-

Phase 2 (Years 2-3): Expand into key neighboring markets such as Saudi Arabia, Oman, and Kuwait, leveraging JAFZA’s logistical advantages.

-

Phase 3 (Years 3+): Explore opportunities in the wider North African region, including Egypt and Morocco, which are also seeing rapid growth in solar energy.

Frequently Asked Questions (FAQ)

What is the estimated capital expenditure for a 200 MW factory?

The investment for a 200 MW turnkey production line, including all machinery and commissioning, typically ranges from USD 15 to 20 million. This does not include the cost of the building or working capital.

What is the typical timeframe from project start to first module production?

With a structured turnkey approach, a facility can become operational within 10 to 14 months of the final investment decision. This includes factory planning, equipment procurement, shipping, installation, and staff training.

Why is a ‘DESERT+’ module necessary for the MENA region?

The region’s high ambient temperatures and intense solar irradiance can cause standard solar modules to degrade faster and produce less power. A ‘DESERT+’ module is specifically engineered with materials and technologies like bifacial cells to ensure long-term performance and a higher energy yield in these harsh conditions.

Is prior experience in solar manufacturing required to undertake such a project?

No, many successful solar manufacturers are entrepreneurs from other industries. The key is to partner with an experienced technical consultant and turnkey provider. They can guide the project from business planning through to full-scale operation, mitigating risks and ensuring adherence to global best practices.

Conclusion: Your Next Steps in Exploring This Opportunity

Establishing a 200 MW export-focused solar module factory in JAFZA represents a timely and strategic investment. It capitalizes on the convergence of a booming regional market, a world-class logistics hub, and a favorable business environment.

By focusing on a specialized, high-performance product engineered for the local climate, a new enterprise can build a durable competitive advantage. While the undertaking is significant, it is an achievable goal. With a clear plan, the right partners, and a structured implementation process, entrepreneurs can confidently enter and succeed in this dynamic industry. The journey begins with thorough education and detailed planning.

Download the JAFZA 200 MW Solar Factory Case Study (PDF)

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.