Disclaimer: This case study represents a composite example derived from real-world

consulting work by J.v.G. Technology GmbH in solar module production and factory optimization. All data points are realistic but simplified for clarity and educational purposes.

For generations, family offices in the United Arab Emirates have built diversified, resilient portfolios that stand the test of time. As the nation pursues a sustainable future, guided by ambitious goals like the UAE Net Zero by 2050 Strategic Initiative, a new class of industrial assets is coming into focus.

For those looking beyond financial instruments toward tangible production, solar module manufacturing presents a compelling opportunity to align wealth preservation with national strategic interests. This is not merely an investment in renewable energy; it is an investment in industrial capacity, supply chain security, and the very infrastructure that will power the nation’s future.

This article outlines an investment framework for UAE-based family offices and private investment firms considering entry into this high-growth sector. It details a structured, de-risked approach to establishing a high-tech solar module factory, accessible even to investors without prior technical expertise in photovoltaics.

The Strategic Imperative: Why Solar Manufacturing in the UAE?

The UAE’s commitment to clean energy is firm and well-documented. The Dubai Clean Energy Strategy 2050 aims for 75% of the emirate’s energy to come from clean sources. Nationwide, the goal is to generate 50% of all power from renewables by 2050. These are not distant targets; they are driving massive utility-scale projects today, such as the Mohammed bin Rashid Al Maktoum Solar Park, one of the largest in the world.

This rapid expansion creates a vast and sustained domestic demand for high-quality solar modules. Currently, a significant portion of these modules is imported, creating a clear strategic gap in the value chain. For investors, this gap represents a durable opportunity.

By establishing local manufacturing, a family office can:

- Capture Domestic Value: Serve the growing needs of national projects and the private sector.

- Enhance Supply Chain Security: Reduce the nation’s reliance on international supply chains, a key lesson from recent global disruptions.

- Align with National Policy: Directly support the ‘Make it in the Emirates’ initiative, potentially unlocking government support and preferential procurement.

- Create a Tangible Asset: Invest in a physical industrial plant that generates long-term value, distinct from the volatility of financial markets.

Deconstructing the Investment: A Phased Approach

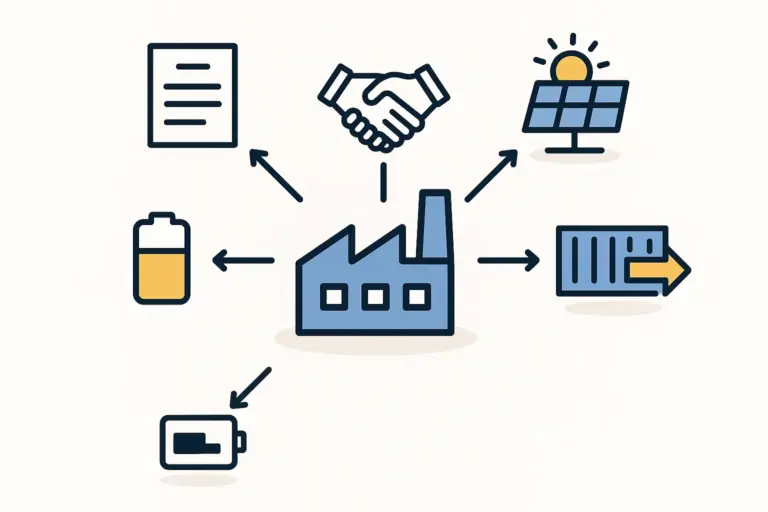

Entering a new industrial sector demands a methodical, risk-managed process. A turnkey partnership model allows the investor to focus on strategic oversight while technical experts manage the complex details of implementation. The process breaks down into three distinct phases.

Phase 1: Due Diligence and Feasibility

The foundation of any successful industrial project is a robust feasibility study. This initial phase moves beyond high-level market data to develop a detailed, bankable plan. Key activities include a thorough analysis of the solar panel manufacturing process, technology selection (e.g., high-efficiency TOPCon or HJT cells), and the development of a comprehensive solar factory business plan. This plan models operational costs, revenue projections, and cash flow under various market scenarios, providing a clear picture of the investment’s financial viability.

Phase 2: Turnkey Setup and Commissioning

Once the decision to proceed is made, the focus shifts to execution. A turnkey approach significantly de-risks this phase. An experienced European turnkey engineering team, manages the entire setup process. This includes factory design, procurement of all solar manufacturing equipment, installation, line integration, and commissioning.

This integrated model ensures that all components work together seamlessly, avoiding costly delays and compatibility issues. Based on experience gained from numerous European PV manufacturers’ turnkey projects, a state-of-the-art 50-100 MW production line can be fully operational in less than 12 months from project start.

Phase 3: Operational Oversight and Management

For an investor without a background in solar technology, managing the day-to-day operations of a factory can seem daunting. This is where a strategic partnership becomes invaluable. This partnership model extends beyond commissioning to include initial operational management.

This involves on-site training for the local workforce, implementing rigorous German-led quality control systems (in line with TÜV and ISO standards), and gradually transferring knowledge. The goal is to build a self-sufficient, highly skilled local team capable of running the plant independently, ensuring the long-term success and value of the asset.

Financial Framework and Risk Management

An investment in solar manufacturing should be evaluated with the same rigor as any other significant portfolio allocation. The financial profile is characterized by a moderate initial capital expenditure followed by a long tail of steady revenue from module sales.

A typical investment for a 50-100 MW semi-automated factory ranges from USD 5 million to USD 10 million. This capital covers all machinery, installation, training, and initial raw materials.

Return on Investment and Projections

The return on investment (ROI) is driven by the consistently falling Levelized Cost of Energy (LCOE) from solar, making it the most affordable source of new electricity generation globally. While market prices for modules fluctuate, a locally produced, high-quality product certified to international standards can command a strong position. This is particularly true when supplying large-scale domestic projects that prioritize reliability and local content. The long-term ROI is realized not just through operational profit but also in the appreciating value of the industrial asset itself.

Risk Mitigation Strategies

A structured investment framework must proactively address potential risks:

- Technology Risk: Partnering with experienced engineers mitigates this risk by selecting proven, high-performance technologies with a clear future roadmap. The focus is on reliability and efficiency, not unproven concepts.

- Operational Risk: The turnkey setup and initial management partnership are designed to eliminate this risk. Quality control is embedded in the process from day one.

- Market Risk: The strong, policy-driven domestic demand in the UAE provides a significant buffer against global market volatility. Furthermore, the ability to serve regional export markets (e.g., Saudi Arabia, Oman) adds another layer of diversification.

The EU-based Photovoltaic Manufacturing Solutions Provider Partnership Model

The model developed by a specialized EU engineering partner offers a clear example of how such a partnership functions. This model offers investors a comprehensive framework to enter the solar manufacturing industry with confidence.

It combines deep technical expertise in turnkey factory implementation with extensive experience in managing industrial operations. This structure allows the investor to function as the strategic sponsor, providing capital and local market insight, while the European engineering partner handles the technical and operational execution. This clear division of responsibilities ensures that all aspects of the project—from initial planning to full-scale production—are managed by seasoned experts.

Comprehensive FAQ for UAE Investors

What is the typical initial investment required?

For a semi-automated 50-100 MW production facility, the initial capital expenditure typically falls between USD 5 million and USD 10 million.

How long does it take for a factory to become operational?

With an experienced turnkey partner managing the project, a new solar module factory can be fully commissioned and producing certified modules in under 12 months.

Is prior technical or manufacturing experience required for the investor?

No. The partnership model is specifically designed for strategic investors without a technical background. The engineering partner manages all technical and operational aspects, ensuring a smooth entry into the market.

What about international certifications and quality standards?

Achieving certifications such as IEC and TÜV is critical for market acceptance. A reputable partner will design the production line and quality control processes to meet these standards from the outset and will manage the entire certification process.

How can a local factory compete with large-scale international imports?

Local manufacturing offers several competitive advantages: superior supply chain reliability, elimination of long-distance shipping costs and risks, faster delivery times, local customer service, and alignment with national ‘Made in the Emirates’ procurement policies.

What does the total solar panel manufacturing plant cost include?

A turnkey investment proposal typically covers all machinery, shipping, installation, commissioning, on-site staff training, initial raw material packages, and support through the certification process.

Conclusion: A Future-Proof Asset Class

For UAE family offices, diversifying into solar module manufacturing is a strategic decision that aligns with both long-term financial objectives and the national vision. It represents a move into a stable, high-demand industrial sector, creating a tangible asset that contributes directly to the country’s energy independence and sustainable development.

With a structured, partnership-based framework, the complexities of technology and operations are expertly managed, enabling investors to participate in one of the most significant economic transitions of our time. The path from initial consideration to a fully operational, profitable manufacturing plant is clear, methodical, and achievable.

Download: UAE Family Office Solar Investment Case Study [PDF]

Author: This case study was prepared by the

turnkey solar module production specialists at J.V.G. Technology GmbH

It is based on real data and consulting experience from J.v.G. projects

worldwide, including installations ranging from 20 MW to 500 MW capacity.