An entrepreneur’s vision for a new solar module factory often centers on state-of-the-art machines, skilled labor, and market demand. A critical and frequently underestimated factor, however, is the stability of the electrical supply powering the entire operation. In a dynamic economy like Uganda’s, assuming the grid will be as reliable as it is in Germany or Japan can lead to costly operational failures.

A brief power fluctuation lasting less than a second is a minor inconvenience in an office. In a solar module factory, it can destroy an entire batch of materials in a high-temperature laminator, leading to thousands of dollars in losses and hours of downtime. Planning for the local power infrastructure, therefore, isn’t just a secondary technical detail; it’s a primary business imperative.

Understanding Uganda’s National Power Landscape

Uganda has made significant strides in expanding its electrical grid. According to World Bank data, access to electricity grew from approximately 11% in 2010 to over 45% by 2022. This impressive growth reflects a national commitment to development. For an industrial investor, however, the story behind these numbers is crucial.

A USAID Power Africa fact sheet notes that over 90% of Uganda’s electricity comes from hydropower. While this is a clean, renewable source, it’s also vulnerable to climate patterns like droughts, which can impact generation capacity. As in many rapidly expanding networks, industrial consumers also face challenges with grid stability, transmission losses, and fluctuating voltage.

For a professional planning a solar factory, this means that while the national grid provides a foundation for operations, relying on it completely introduces an unacceptable level of business risk. A detailed analysis of the local grid’s performance history is therefore an essential step in the due diligence process when assessing the right location.

The Real Cost of Unstable Power for a Solar Factory

The financial impact of power interruptions goes far beyond a temporary shutdown. A semi-automated 50 MW solar module production line requires a continuous power supply of approximately 250–350 kWh, and its critical machinery is highly sensitive to power quality.

Consequences of Power Failure:

-

Material Waste: The most immediate impact is on machines like the laminator. An interrupted lamination cycle—where layers of glass, EVA, and solar cells are bonded under heat and pressure—is irreversible. The entire module, and often several others in the same batch, must be discarded.

-

Equipment Damage: Modern production equipment, such as stringers that precisely solder solar cells together, contains sensitive electronic controls. Abrupt power cuts or surges can damage these components, leading to expensive repairs and extended downtime.

-

Lost Production: Every hour the factory is not running represents lost revenue and a potential failure to meet client delivery schedules.

This is not a theoretical risk. Julius Etim, a factory owner in Nigeria who established a plant with J.v.G. Technology GmbH, shared his early experience: ‘We underestimated the impact of micro-outages. The first month, we lost nearly 15% of our raw materials in the laminator due to split-second power cuts. Planning for a UPS and a backup generator was the best decision we made.’

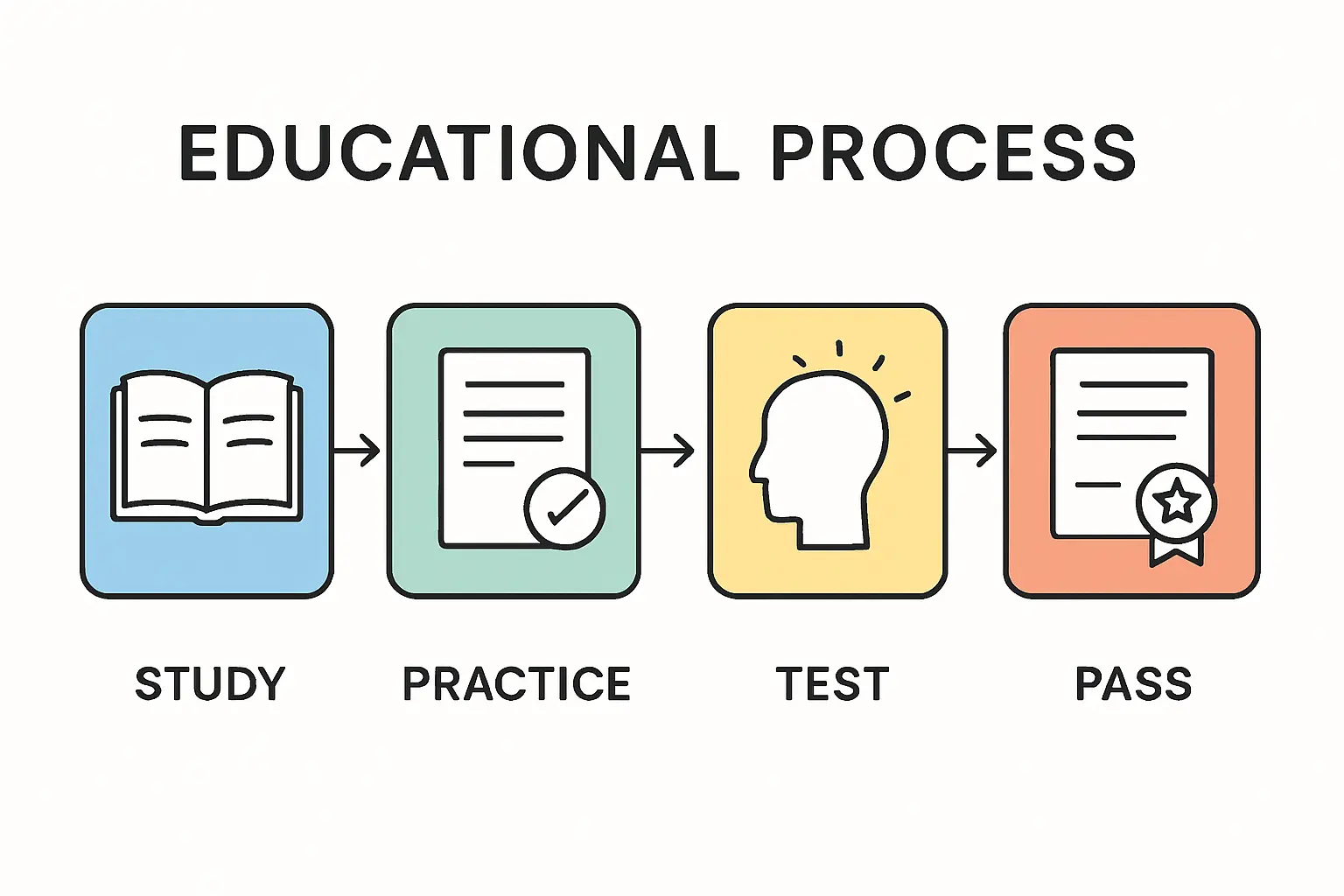

A Two-Layered Strategy for Power Stability

To insulate a manufacturing operation from grid volatility, a robust, two-layered backup power system is industry standard. This strategy ensures production can continue seamlessly, regardless of external power conditions.

Layer 1: The Uninterruptible Power Supply (UPS) for Critical Loads

An industrial UPS is essentially a large, sophisticated battery system. Its purpose isn’t to run the factory for hours, but to supply instant, clean, and uninterrupted power to the most sensitive machines—primarily the laminator and stringer—the moment a grid irregularity is detected.

This system acts as a bridge, covering the critical seconds or minutes between a grid failure and the backup generator taking over. It completely eliminates the threat of ‘micro-outages’ that can be so destructive to production processes.

Layer 2: The Standby Generator for Sustained Operation

For power outages lasting longer than a few minutes, a standby generator is essential. Typically powered by diesel, this unit is sized to handle the entire factory’s electrical load, from production machines to lighting and air conditioning.

When the grid fails, an automatic transfer switch (ATS) signals the generator to start. Once it reaches a stable operating speed, the ATS transfers the factory’s electrical load from the grid to the generator. This process usually takes less than a minute, during which the UPS has kept all critical systems operating without interruption.

Integrating Power Planning into Your Business Case

The cost of a UPS and a suitably sized generator is a significant capital expense. However, it shouldn’t be viewed as an optional add-on, but as an essential insurance policy protecting the entire multi-million dollar investment in the factory.

This cost must be factored into the initial financial model for a solar factory from day one. Failing to do so can lead to budget overruns or, worse, a decision to proceed without adequate backup power, exposing the business to severe operational and financial risks. When structuring a turnkey solar production line, experienced technical partners make the design and commissioning of the power backup system a core part of the project plan.

Frequently Asked Questions (FAQ)

Q: Can the solar factory power itself with the panels it produces?

A: While theoretically possible, it’s not practical or economically viable. A production line requires a massive, constant, and stable supply of power, 24 hours a day. Powering it with solar would require an enormous battery storage system far exceeding the cost of a generator. The primary business goal is to manufacture and sell modules, not consume them for internal operations.

Q: What is the typical investment for a generator and UPS system?

A: The investment varies based on the factory’s size (e.g., 50 MW vs. 200 MW) and the specific equipment used. As a general estimate, a comprehensive power backup system can account for 5–10% of the total machinery investment. It’s a necessary cost to guarantee production continuity.

Q: How much fuel should be kept on-site for a backup generator?

A: This depends on the reliability of the local fuel supply chain and the typical duration of power outages in the area. It’s prudent to maintain a fuel reserve sufficient to run the factory for a minimum of 48 to 72 hours continuously.

Conclusion: From Planning to Production Certainty

Entering the solar manufacturing industry in a market like Uganda offers immense potential. Success, however, depends on a clear-eyed assessment of local operating conditions. By acknowledging the realities of the developing power grid and proactively investing in a robust backup power infrastructure, an entrepreneur turns a significant business risk into a manageable operational challenge. This foresight is what separates a struggling plant from a highly efficient and profitable manufacturing business.