A Practical Guide to Building a Technical Workforce for a Solar Factory Near Kampala

When planning a solar module factory, an entrepreneur’s focus often falls first on machinery and capital. Yet, experience from countless turnkey projects shows that the most critical long-term asset is the technical team.

Without a skilled and well-trained workforce, even the most advanced equipment will fail to deliver on its promise of output and quality. For a new venture in Uganda, sourcing and training this workforce successfully is paramount.

The challenge may seem daunting, especially in a market where solar manufacturing is not yet widespread. But Uganda, particularly the area around its economic hub of Kampala, presents a unique opportunity.

With over 77% of its population under 30 and a government committed to increasing solar capacity to 3,200 MW by 2040, the key elements for success are already in place. This guide outlines a practical, structured approach to building a competent technical team for a solar module assembly plant near Kampala.

The Strategic Advantage of Kampala’s Labor Pool

Kampala is the commercial and industrial heart of Uganda. For a new manufacturing enterprise, proximity to this hub offers logistical benefits, access to services, and, most importantly, a concentration of human capital. The region’s high solar irradiation of 5.1 kWh/m²/day provides the natural resource, while its young, growing population provides the human one.

This demographic advantage is supported by a national focus on vocational skills. The Ugandan government, often partnering with international bodies like GIZ and the World Bank, has placed a strong emphasis on Technical and Vocational Education and Training (TVET).

This focus creates a pool of individuals with foundational technical aptitudes, making them ideal candidates for specialized training in solar module assembly. Investors are not starting from scratch; they are building on an existing educational framework.

Identifying the Right Skill Sets for Solar Module Assembly

A common misconception is that a solar factory requires a large team of highly specialized engineers. In reality, a well-designed 20-50 MW production line can be run efficiently by a core team of 20-30 technicians who possess the right foundational skills. The key is not to find pre-existing solar experts but to recruit individuals with transferable technical skills.

The most critical roles and their required skills include:

-

Machine Operators: Individuals with a background in electronics or electromechanical systems are well-suited for this role. They must be detail-oriented to manage equipment like solar cell stringers and laminators.

-

Maintenance Technicians: A strong foundation in mechanical and electrical maintenance is essential. Their role is to ensure maximum uptime by performing preventive maintenance and troubleshooting equipment.

-

Quality Control Inspectors: This role requires meticulous attention to detail and an understanding of process standards. Technicians trained in general quality assurance or electronics inspection can adapt quickly to processes like electroluminescence (EL) testing and visual inspection of finished modules.

-

Logistics and Materials Handlers: While less technical, these roles are crucial for a smooth production flow. Experience in a manufacturing or warehouse environment is beneficial.

Sourcing Talent: Collaboration with Technical Institutions

The most effective recruitment strategy is to build direct relationships with Uganda’s leading technical and vocational institutes. They are the primary source of talent with the desired foundational skills. Engaging with these institutions allows a new enterprise to create a sustainable pipeline of qualified candidates.

Key institutions in and around Kampala include:

-

Uganda Technical Colleges (UTCs): Campuses like UTC Kyema and UTC Bushenyi offer diplomas and certificates in electrical, mechanical, and civil engineering disciplines.

-

Nakawa Vocational Training Institute (NVTI): Known for its practical, hands-on training programs in areas directly applicable to a manufacturing environment.

-

Kyambogo University: The university’s Faculty of Engineering provides a source for supervisors and managers with a deeper theoretical understanding of engineering principles.

A proactive approach includes contacting career services departments, participating in job fairs, and offering internships or apprenticeships. This not only helps with recruitment but also establishes the new factory as a desirable local employer. For a broader perspective, the Labor Market Overview for Solar Manufacturing in East Africa provides additional context on regional trends.

Building In-House Expertise: The Critical Role of Training

Recruiting individuals with the right aptitude is only the first step. Solar module manufacturing involves specific processes and quality standards that demand dedicated training. A structured in-house training program is essential for achieving consistent output and long-term success.

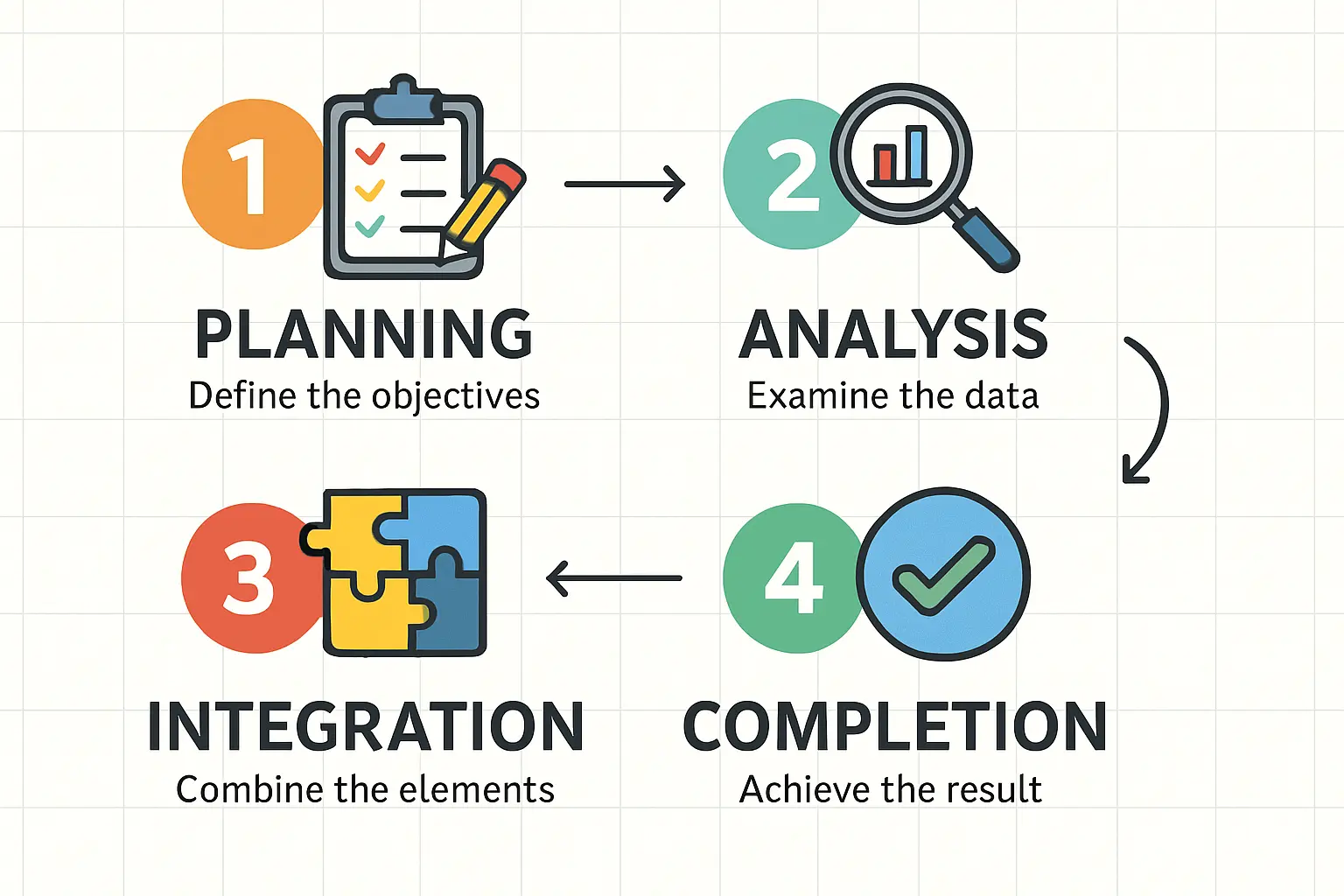

This training is typically divided into two phases:

Phase 1: Foundational Classroom Training

Before operators touch any equipment, they must understand the ‘why’ behind their tasks. This phase, often lasting several weeks, covers theoretical concepts, safety protocols, quality standards (such as IEC 61215), and the function of each machine in the production line.

Phase 2: On-the-Job Practical Training

Following classroom instruction, trainees move to the factory floor under the supervision of experienced trainers, often provided by the turnkey equipment supplier like J.v.G. Technology. This hands-on phase allows them to apply their knowledge, develop muscle memory for delicate tasks, and learn troubleshooting on the actual production equipment. The guidance of a skilled production manager is crucial during this period to ensure best practices are embedded from day one. Understanding The Role of a Production Manager in a Solar Factory is essential for investors planning their management structure.

This methodical approach ensures that local staff are not just taught to operate machines but are empowered to become self-sufficient technical experts. As Mr. Julius Etim, an entrepreneur who established a solar factory in Nigeria, noted based on his experience, ‘The on-site training from the German engineers was the turning point. Our local team went from being cautious operators to confident technicians who could solve problems independently. This transfer of knowledge was more valuable than the hardware itself.’

Frequently Asked Questions (FAQ)

How many technical staff are needed to start a small-scale factory?

A typical 20-50 MW semi-automated assembly line requires a workforce of approximately 20 to 30 employees. This includes operators for two shifts, maintenance staff, quality control inspectors, and a production supervisor.

What is the typical timeline for training a new team from scratch?

A comprehensive training program, from classroom instruction through to confident operation on the factory floor, generally takes between three and six months. The initial period is intensive, with ongoing coaching required as production ramps up.

Is prior experience in the solar industry necessary for new hires?

No, it is not a prerequisite. It is more important to hire for attitude, technical aptitude, and a willingness to learn. A robust training program can effectively bridge the knowledge gap for individuals with a background in general electronics, mechanics, or manufacturing.

What is the role of expatriate staff in a new factory?

Expatriate experts are often vital during the setup and initial ramp-up phases. Their primary role is to oversee equipment commissioning and lead the initial training of the local management and technical team. The long-term goal should always be a complete knowledge transfer to achieve full operational autonomy with local staff.

Next Steps in Your Project Planning

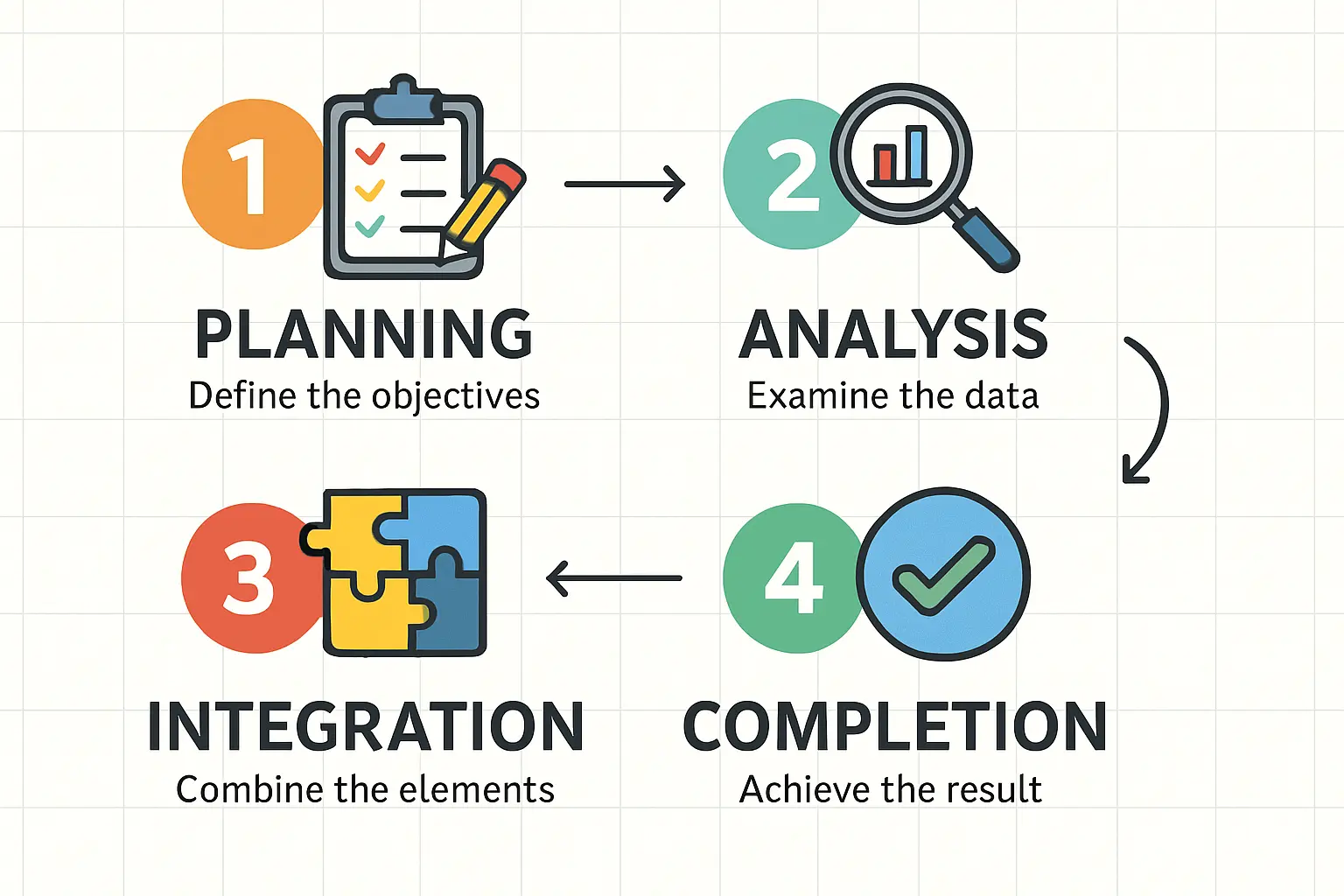

Building a competent workforce is a cornerstone of any successful solar manufacturing business. It requires a strategic approach that begins with understanding the local labor market and culminates in a rigorous, well-structured training program.

With this foundation in human capital, an investor can more confidently tackle other critical aspects of the project, such as selecting the right machinery, designing the factory layout, and securing the necessary certifications. Each element builds on the last, leading toward a resilient and profitable enterprise.